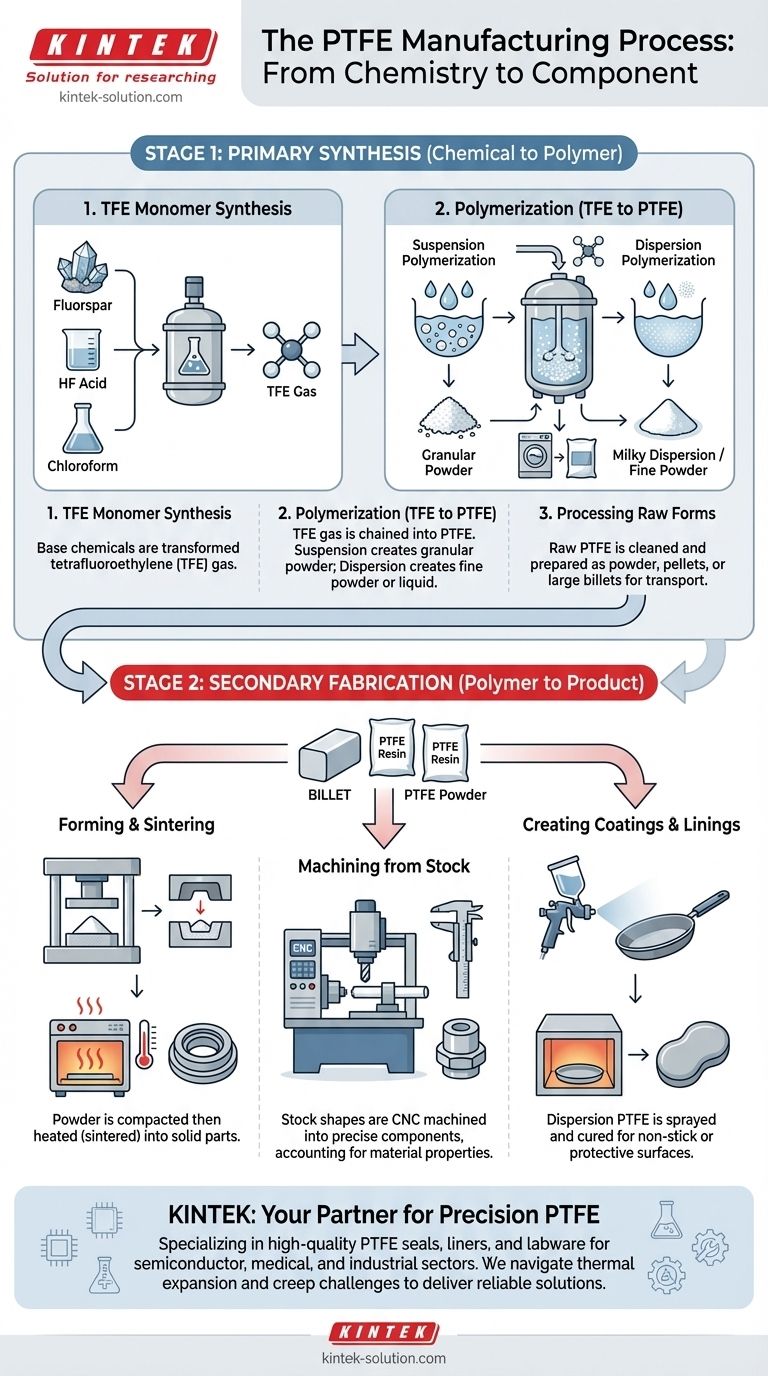

At its core, the manufacturing of Polytetrafluoroethylene (PTFE) involves a highly controlled chemical process. The fundamental steps are the synthesis of the tetrafluoroethylene (TFE) monomer from base chemicals, the polymerization of this monomer into raw PTFE, and finally, the processing of this raw polymer into a usable form for industrial applications.

Understanding PTFE manufacturing requires seeing it as two distinct stages. The first is the chemical synthesis of the raw polymer, and the second is the physical processing of that polymer into a finished product like a machined part or a non-stick coating.

The Foundational Synthesis: From Raw Materials to Polymer

The creation of PTFE begins at a chemical level, transforming common industrial chemicals into a high-performance polymer. This is the primary stage of manufacturing.

Step 1: Synthesizing the TFE Monomer

The journey starts by creating the essential building block: tetrafluoroethylene (TFE) gas. This process begins with ingredients like fluorspar, hydrofluoric acid, and chloroform.

These raw materials undergo a multi-stage synthesis, first producing chlorodifluoromethane. This intermediate compound is then heated to create the TFE monomer, the molecule that will be linked together to form PTFE.

Step 2: Polymerizing TFE into PTFE

Polymerization is the chemical reaction where individual TFE monomer molecules are chained together to form long, stable polymer chains of PTFE. There are two primary methods for this, each yielding a different form of raw material.

- Suspension Polymerization: In this method, the reaction occurs in water, resulting in grainy, larger particles of PTFE. This granular powder is ideal for molding into solid stock shapes like rods, tubes, and sheets.

- Dispersion Polymerization: This process also uses water but produces much smaller, finer PTFE particles. The result is a milky dispersion that is perfect for creating coatings and films or can be processed into a fine powder for specialized molding.

Step 3: Processing Raw PTFE into Usable Forms

The raw PTFE from the polymerization reactor is not yet a finished product. It must be processed into a stable, transportable, and usable format.

The granular resins or fine powders are washed, dried, and prepared. They may be sold as powders, converted into pellets, or pre-formed into large blocks called billets that serve as the raw material for secondary manufacturing.

From Raw Polymer to Finished Part: Secondary Manufacturing

Once the raw PTFE polymer is synthesized, it must be fabricated into a final component. This secondary stage is what most engineers and designers interact with.

Forming and Sintering

For many solid parts, granular PTFE powder is compressed into a desired shape using a mold—a process called compaction.

This "green" part is then heated in a controlled oven to a high temperature below its melting point. This step, known as sintering, causes the PTFE particles to fuse into a solid, durable mass.

Machining from Stock Shapes

Many PTFE components are CNC machined from pre-made stock shapes (rods, sheets). While PTFE is soft and easy to cut, achieving precision can be challenging.

Its properties demand special consideration, including a high coefficient of thermal expansion (it changes size with temperature), a tendency to compress under clamping pressure, and a propensity for stress creep (slow deformation). Using extremely sharp tools and moderate cutting speeds is critical to prevent heat buildup and ensure dimensional accuracy.

Creating Coatings and Linings

For applications like non-stick pans or corrosion-resistant tank linings, the dispersion-grade PTFE is used. The liquid dispersion is sprayed or applied to a prepared surface.

The object is then heated, which evaporates the liquid and bonds the PTFE layer to the substrate, creating a durable, low-friction surface.

Understanding the Trade-offs

The properties that make PTFE uniquely useful also create its manufacturing challenges. Ignoring them leads to component failure.

Thermal Expansion is a Critical Factor

PTFE expands and contracts with temperature changes more than almost any other plastic. During machining, heat from cutting can cause the material to expand, leading to inaccurate final dimensions once it cools. This must be managed with coolants or controlled cutting strategies.

Softness and Creep Limit Precision

PTFE's softness makes it easy to machine but difficult to hold tight tolerances. Over-tightening clamps during machining will deform the part. Furthermore, under a constant load, PTFE will slowly deform over time—a phenomenon known as creep—which must be accounted for in the design of seals and gaskets.

Sintering Determines Final Quality

The final properties of a molded PTFE part are highly dependent on the sintering process. Improper temperature control, heating rates, or cooling cycles can result in a part with poor mechanical strength, high porosity, or internal stresses.

Making the Right Choice for Your Application

Your end-use application should dictate which manufacturing path and PTFE grade you choose.

- If your primary focus is machined seals, bearings, or insulators: You will start with stock shapes made from granular PTFE, and your design must account for thermal expansion and creep during machining and in final use.

- If your primary focus is non-stick surfaces or chemical-resistant linings: You will use a product made from dispersion-grade PTFE, and the quality will depend heavily on the surface preparation and application process.

- If your primary focus is high-purity components for medical or semiconductor use: The specific polymerization route and any processing aids are critical, as trace contaminants can be a significant issue.

By understanding both the chemical origin and the physical fabrication of PTFE, you can make more informed decisions and design more reliable products.

Summary Table:

| Manufacturing Stage | Key Steps | Resulting PTFE Form |

|---|---|---|

| Primary (Chemical Synthesis) | 1. TFE Monomer Synthesis 2. Polymerization (Suspension/Dispersion) |

Granular Resin or Fine Powder |

| Secondary (Fabrication) | 3. Processing (Compaction, Sintering, Machining, Coating) | Finished Parts (Seals, Liners, Labware, etc.) |

Need Precision PTFE Components for Your Industry?

Understanding the intricacies of PTFE manufacturing is key to specifying the right material and process for your application. KINTEK specializes in manufacturing high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine deep material expertise with precision production, offering everything from custom prototypes to high-volume orders. Let us help you navigate the challenges of thermal expansion, creep, and sintering to deliver a component that performs reliably.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the monomer used in the preparation of PTFE? Mastering the Synthesis of Tetrafluoroethylene

- What are the key takeaways about PTFE and expanded PTFE? Choosing the Right High-Performance Polymer

- Why is flow regulation important in control systems? Ensure Stability, Safety, and Efficiency

- How are fillers used to enhance PTFE properties? Boost Wear, Strength, and Thermal Performance

- What makes PTFE suitable for electrical applications? Superior Insulation for Demanding Environments

- What makes PTFE/Teflon suitable for medical applications? Discover Its Unique Biocompatibility & Performance

- How does material selection impact PCB manufacturing and cost? Optimize Performance and Budget

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments