To be direct, PTFE-lined bottle caps are exceptionally reusable and highly durable. Their construction is engineered for demanding applications, allowing for repeated sterilization cycles via autoclaving without degrading. They are designed to resist wear from both aggressive chemical exposure and long-term physical use.

The core strength of a PTFE-lined cap is its resilient integrity. The unique combination of chemical inertness, extreme temperature stability, and physical robustness ensures it maintains a protective, non-reactive seal through repeated use in the most challenging environments.

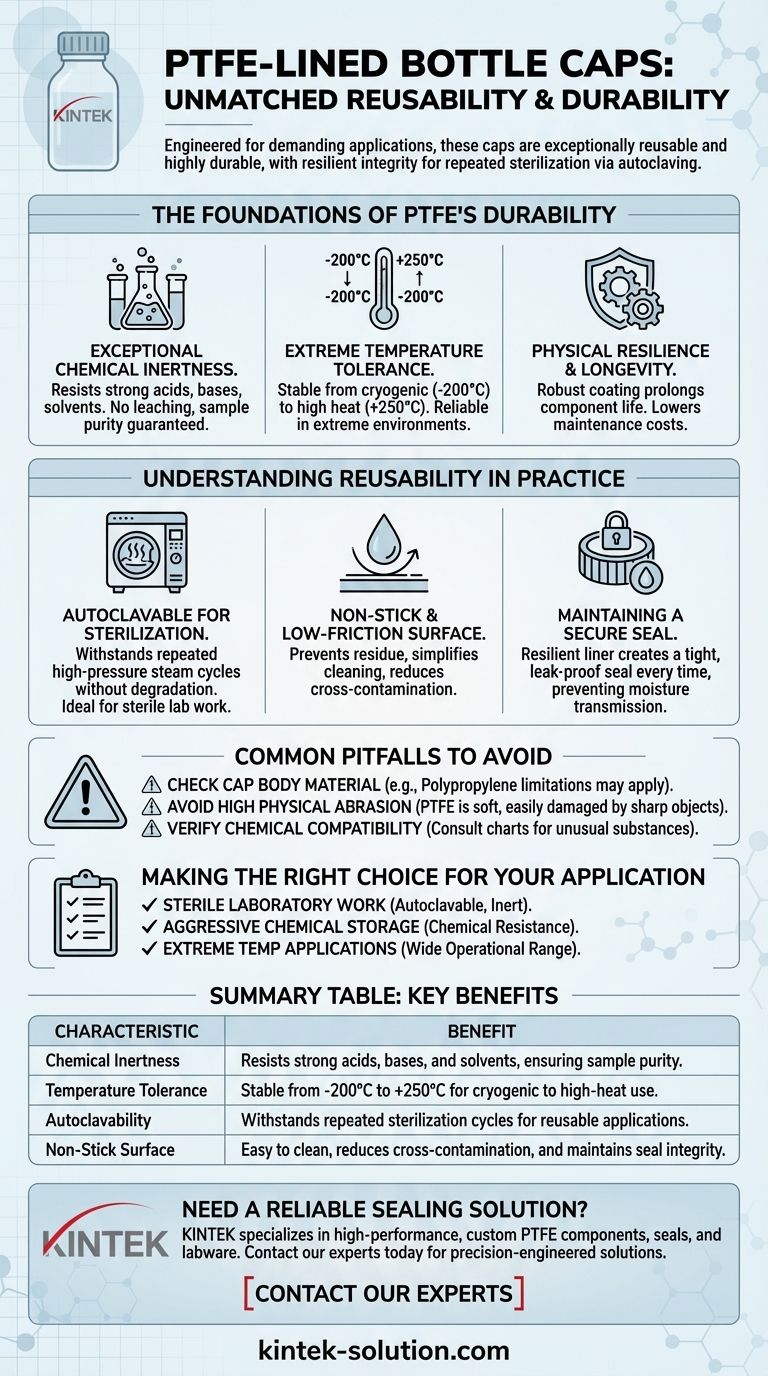

The Foundations of PTFE's Durability

To understand why these caps are so reliable, we must look at the intrinsic properties of Polytetrafluoroethylene (PTFE), the material used for the liner.

Exceptional Chemical Inertness

The primary feature of PTFE is its status as one of the most non-reactive materials known. It is highly resistant to a vast range of substances.

This includes strong acids, bases, solvents, and other corrosive chemicals. The liner does not react with, nor does it leach into, the stored contents, ensuring sample purity.

Extreme Temperature Tolerance

PTFE maintains its properties across an exceptionally wide temperature range, typically from -200°C to +250°C (-328°F to +482°F).

This thermal stability means the liner will not become brittle in cryogenic conditions or degrade under high heat, ensuring a consistent and reliable seal in extreme environments.

Physical Resilience and Longevity

The PTFE coating is robust and designed to prolong the life of the component. It is highly resistant to wear and tear under normal laboratory and industrial conditions.

This durability reduces the need for frequent replacement and lowers long-term maintenance costs, ensuring equipment remains operational and reliable.

Understanding Reusability in Practice

Durability is meaningless if a component cannot be reliably reused. PTFE liners are engineered specifically for a multi-use lifecycle.

Autoclavable for Sterilization

A key feature enabling reuse is autoclavability. These caps can withstand repeated sterilization cycles with high-pressure steam without compromising the liner's integrity.

This makes them ideal for applications in pharmaceutical, medical, and biological laboratories where sterility is non-negotiable.

Non-Stick and Low-Friction Surface

PTFE's famous "non-stick" property prevents residue from adhering to the liner surface. This simplifies cleaning procedures and reduces the risk of cross-contamination between uses.

The low-friction nature of the material also allows the cap to be screwed on and off easily without binding, preserving the integrity of both the cap's threads and the seal itself.

Maintaining a Secure Seal

The combination of PTFE's resilience and low friction ensures that the liner can create a tight, leak-proof seal over and over again. It effectively prevents moisture transmission, protecting the contents from the outside environment.

Common Pitfalls to Avoid

While highly effective, understanding the complete system is crucial for proper application and avoiding failure.

The Liner vs. The Cap Body

The PTFE liner provides the chemical and thermal resistance. However, the cap body itself is often made from a different material, such as polypropylene.

The cap's overall performance is limited by its weakest component. Always verify that the temperature and chemical resistance of the cap body are also suitable for your specific application.

Physical Abrasion

PTFE offers excellent chemical resistance but is a relatively soft material. While resistant to general wear, it is not intended for high-abrasion environments. Repeated contact with sharp or abrasive materials can physically damage the liner, compromising the seal.

Compatibility Verification

Although PTFE is resistant to most chemicals, it is not universally inert. It's always best practice to consult a detailed chemical compatibility chart before using these caps with highly aggressive or unusual substances to ensure long-term integrity.

Making the Right Choice for Your Application

Selecting the correct components is critical for safety and experimental success. Your decision should be based on the primary demand of your task.

- If your primary focus is sterile laboratory work: The certified non-toxic, inert properties combined with proven autoclavability make these caps a reliable choice for maintaining sample purity.

- If your primary focus is long-term storage of aggressive chemicals: The exceptional chemical resistance of the PTFE liner ensures the integrity of both the stored substance and the seal over time.

- If your primary focus is high or low-temperature applications: The liner's vast operational temperature range provides a dependable seal in environments where other materials would fail.

Ultimately, PTFE-lined caps provide a robust and reliable sealing solution for your most critical applications.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents, ensuring sample purity. |

| Temperature Tolerance | Stable from -200°C to +250°C for cryogenic to high-heat use. |

| Autoclavability | Withstands repeated sterilization cycles for reusable applications. |

| Non-Stick Surface | Easy to clean, reduces cross-contamination, and maintains seal integrity. |

Need a reliable sealing solution for demanding applications?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE-lined caps are designed for maximum reusability and durability, ensuring long-term reliability and cost-effectiveness for your critical processes.

Contact our experts today to discuss your specific requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- What are PTFE ferromagnetic support discs composed of? A Dual-Material Design for Superior Grinding & Polishing

- What are the benefits of using a PTFE safety cover? Enhance Safety, Cut Costs & Mitigate Hazards

- How does the ergonomic design of PTFE shovels benefit users? Reduce Strain and Boost Lab Efficiency

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- What types of PTFE labware are commonly available? Find the Right Tools for Your Lab

- Why is vial type and size compatibility important for PTFE-coated septums? Ensure a Perfect Seal for Reliable Results

- How should PTFE plugs be handled with corrosive liquids? Prevent Costly Glassware Damage