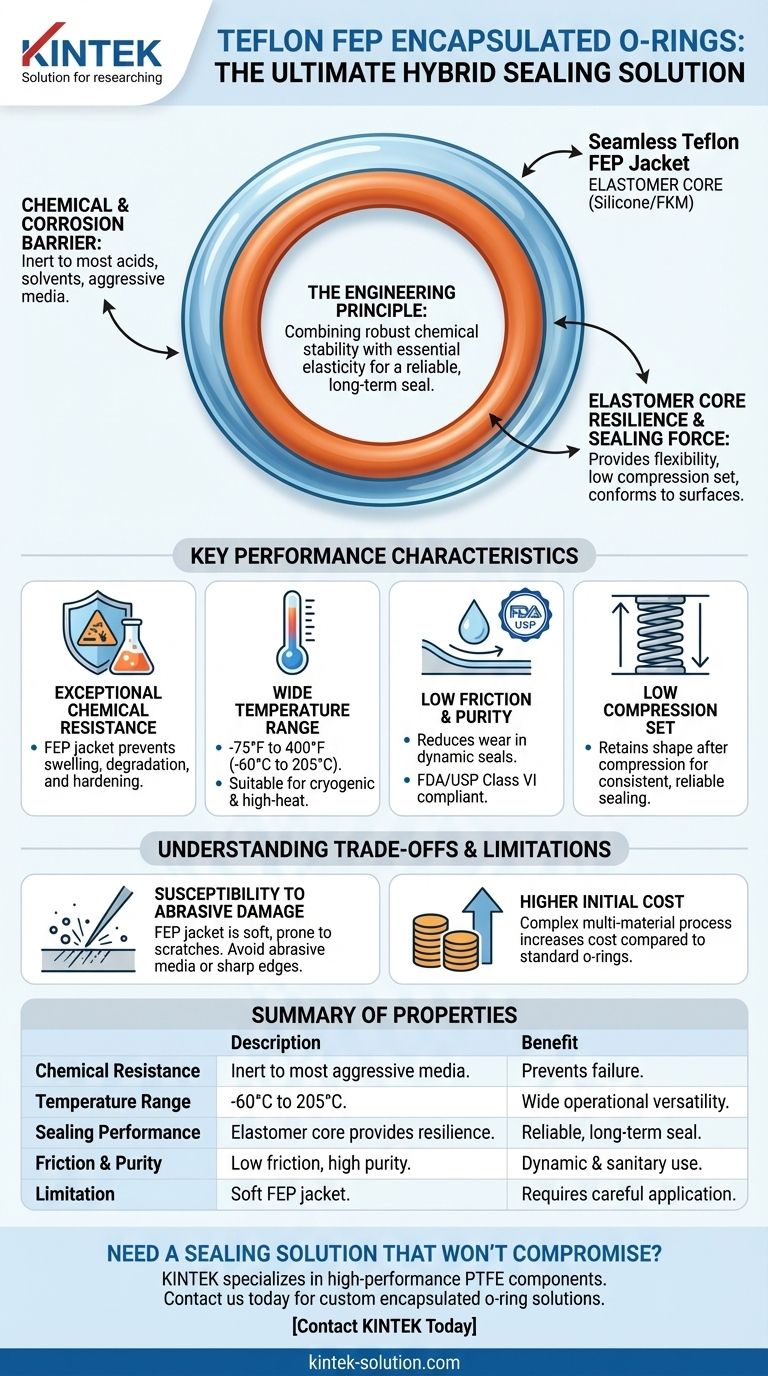

At their core, Teflon FEP encapsulated o-rings are composite seals that combine the exceptional chemical inertness and temperature resistance of a Teflon FEP outer jacket with the flexibility and compression of an inner elastomer core, typically silicone or FKM (Viton). This hybrid design provides a unique sealing solution for demanding applications where a standard elastomer o-ring would quickly fail.

The central takeaway is that encapsulated o-rings solve a fundamental engineering conflict: they provide the robust chemical and thermal stability of Teflon without sacrificing the essential elasticity needed for a reliable, long-term seal.

The Engineering Principle: A Hybrid Design

The effectiveness of an encapsulated o-ring comes from its two-part construction. Each component is chosen specifically to contribute a property the other lacks, resulting in a seal that is greater than the sum of its parts.

The Seamless Teflon Jacket

The outer layer is a seamless jacket made of Fluorinated Ethylene Propylene (FEP), a type of Teflon. This jacket is the primary barrier against the operating environment.

Its main function is to provide outstanding chemical and corrosion resistance against a broad spectrum of aggressive media, including acids, solvents, and petroleum spirits.

The Elastomer Core

Inside the jacket lies a solid or hollow core made of an elastomer like silicone or FKM (Viton). Standard Teflon is rigid and has poor "memory," meaning it doesn't spring back into shape after being compressed.

The elastomer core provides the resilience, flexibility, and sealing force that the Teflon jacket lacks. It is this core that allows the o-ring to conform to surface imperfections and maintain a tight seal under pressure.

How They Work Together

The design is simple yet effective: the Teflon jacket completely protects the vulnerable elastomer core from chemical attack. In turn, the core provides the constant, gentle pressure needed for the Teflon jacket to maintain a reliable seal against the hardware surfaces.

Key Performance Characteristics

This dual-material construction results in a unique set of properties that define its use in challenging industrial, chemical, and pharmaceutical applications.

Exceptional Chemical Resistance

The FEP jacket makes the o-ring inert to nearly all industrial chemicals and solvents. This prevents the swelling, degradation, or hardening that would cause a standard o-ring to fail.

Wide Temperature Range

The combination of materials allows for a very broad operational temperature range, typically from -75°F to 400°F (-60°C to 205°C). This accommodates applications involving both cryogenic and high-heat processes.

Low Friction and Contamination

Teflon is known for its extremely low coefficient of friction, which reduces wear and drag in dynamic sealing applications. Furthermore, the materials used are often FDA compliant and USP Class VI approved, making them suitable for sanitary processes.

Low Compression Set

Thanks to the elastomer core, these o-rings exhibit a low compression set. This means they effectively retain their original shape after being compressed for long periods, ensuring a consistent and reliable seal throughout their service life.

Understanding the Trade-offs and Limitations

While highly effective, encapsulated o-rings are not a universal solution. Their specialized construction introduces specific limitations that must be considered.

Susceptibility to Abrasive Damage

The primary weakness is the Teflon jacket's relative softness. It is prone to scratching and damage in applications involving abrasive media or sharp edges on hardware. Any breach of the jacket will expose the core and lead to rapid failure.

Higher Initial Cost

The complex, multi-material manufacturing process makes encapsulated o-rings more expensive than both standard elastomer o-rings and solid Teflon o-rings. This cost must be justified by the demands of the application.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to the specific challenges of your operating environment.

- If your primary focus is sealing against highly corrosive chemicals: The FEP jacket provides the near-universal chemical inertness required for these applications.

- If your primary focus is reliable sealing across a wide temperature spectrum: The combination of an FEP jacket and a stable silicone or FKM core is an excellent choice.

- If your primary focus is a dynamic seal in an environment with abrasive particles: You should exercise caution, as the FEP jacket can be damaged and a more robust material may be required.

Ultimately, an FEP encapsulated o-ring is a precision-engineered solution for when you cannot afford to compromise on chemical resistance but still require the physical performance of an elastic seal.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Resistance | Outer FEP Teflon jacket is inert to most acids, solvents, and aggressive media. | Prevents swelling, degradation, and failure of the seal. |

| Temperature Range | Operates from -75°F to 400°F (-60°C to 205°C). | Suitable for both cryogenic and high-heat processes. |

| Sealing Performance | Elastomer core (silicone/FKM) provides resilience and a low compression set. | Ensures a reliable, long-term seal by conforming to surfaces. |

| Friction & Purity | Low coefficient of friction; materials are often FDA/USP Class VI compliant. | Ideal for dynamic seals and sanitary applications like pharmaceuticals. |

| Limitation | FEP jacket is soft and can be damaged by abrasive particles or sharp edges. | Requires careful consideration of the operating environment. |

Need a sealing solution that won't compromise?

Teflon FEP encapsulated o-rings are precision-engineered for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom encapsulated o-rings.

We deliver the precision and reliability your application demands, from prototyping to high-volume production.

Contact KINTEK today to discuss your specific sealing challenges and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance