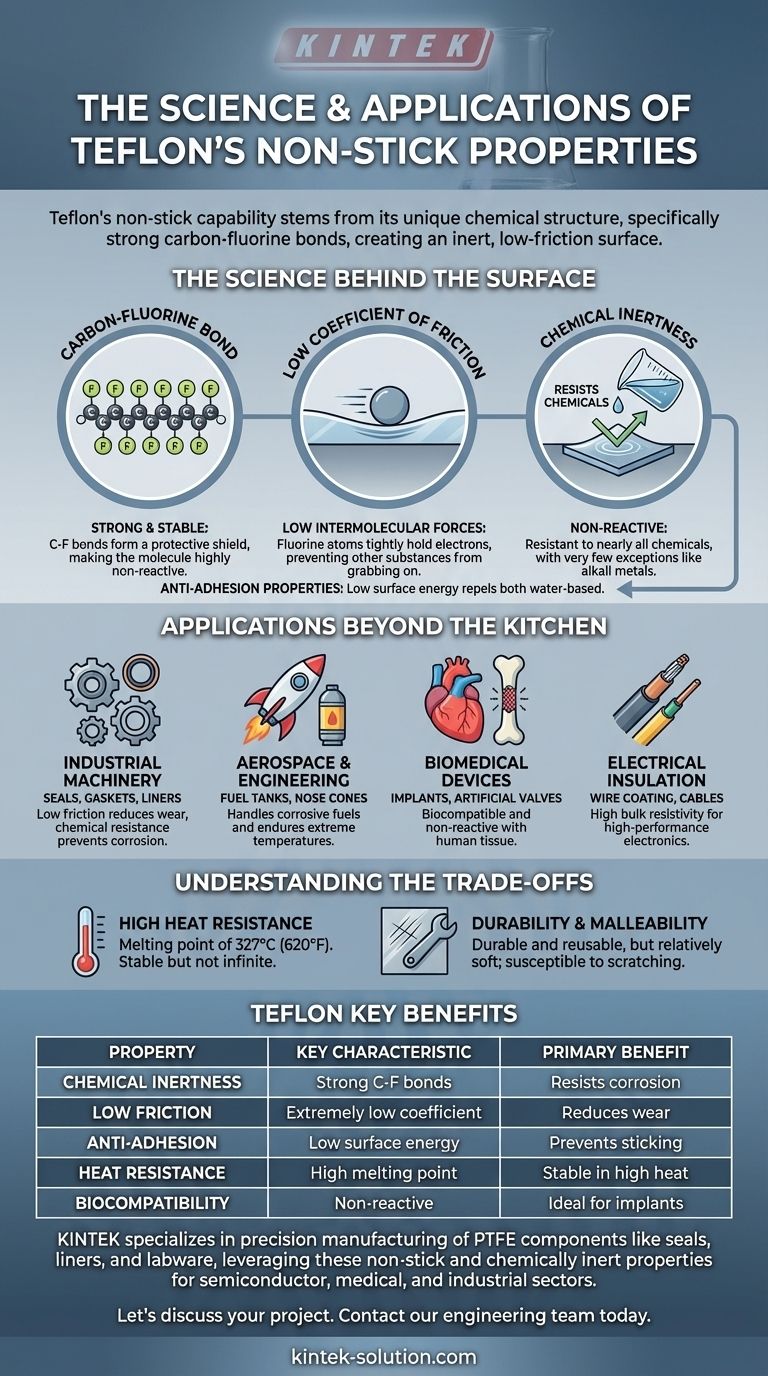

At its core, Teflon's famous non-stick property is a direct result of its unique chemical structure, specifically the incredibly strong and stable bonds between carbon and fluorine atoms. This creates a chemically inert, low-friction surface that prevents other materials from adhering to it, a characteristic most famously applied to cookware but essential in a vast range of industrial and technical fields.

The key insight is that Teflon's non-stick nature isn't just a surface effect; it's an intrinsic property of the material itself. This inherent chemical stability is what makes it invaluable not only in kitchens but also in demanding aerospace, medical, and industrial environments where reliability is critical.

The Science Behind Teflon's Non-Stick Surface

To understand Teflon's applications, you must first understand the fundamental properties that make it so unique. Its performance is rooted in its molecular composition.

The Carbon-Fluorine Bond

Teflon, or Polytetrafluoroethylene (PTFE), is a polymer consisting of a long chain of carbon atoms completely surrounded by fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable.

This structure creates a molecule that is highly non-reactive. It effectively shields the carbon backbone from interacting with other chemicals.

Low Coefficient of Friction

Because the fluorine atoms hold their electrons so tightly, they create a surface with very low intermolecular forces. This results in an extremely low coefficient of friction.

In practical terms, this means other substances have little to nothing to "grab onto" at the molecular level, causing them to slide right off.

Chemical Inertness

Teflon is resistant to nearly all chemicals, with only rare substances like alkali metals being able to affect it.

This chemical inertness is a crucial component of its non-stick capability. If a material cannot chemically react with a surface, it is far less likely to bond with it.

Anti-Adhesion Properties

The combination of these factors gives Teflon powerful anti-adhesion characteristics. It has a low surface energy, meaning it repels both water-based and oil-based substances.

This prevents materials from "wetting" the surface, which is the first step in adhesion.

Applications Beyond the Kitchen

While non-stick cookware is its most famous application, it represents only a fraction of Teflon's use. Its properties are critical in sectors where performance cannot be compromised.

Industrial Machinery

Machined Teflon is widely used to create seals, gaskets, and liners for pipes and tanks. Its low friction reduces wear on moving parts, and its chemical resistance prevents corrosion from harsh industrial materials.

Aerospace and Engineering

In aerospace, Teflon is used in fuel tanks and systems because it can handle corrosive fuels without degrading.

Its high heat resistance also makes it suitable for components like nose cones and heat shields that must endure extreme temperatures.

Biomedical Devices

Because Teflon is chemically inert, the human body does not reject it. This biocompatibility makes it essential for medical applications like artificial heart valves, dentures, and synthetic bone grafts.

Electrical Insulation

The same strong carbon-fluorine bonds that provide chemical stability also make Teflon an excellent electrical insulator. It has very high bulk resistivity, making it ideal for coating wires and cables, especially in high-performance electronics.

Understanding the Trade-offs

No material is perfect for every situation. Understanding Teflon's properties also means recognizing its practical limitations.

High Heat Resistance

Teflon has a high melting point of 600 K (327°C / 620°F), making it stable for most applications, including cooking. However, it is not infinite and has operational temperature limits that must be respected in industrial design.

Durability and Malleability

Teflon is a durable and reusable material that can last for many years. However, it is also relatively soft and malleable compared to metals.

This malleability is an advantage when machining precise gaskets, but it is also why Teflon coatings on cookware can be scratched by sharp metal utensils.

Water Absorption

Teflon has a very low water absorption capacity. This is a significant benefit in most applications, preventing swelling or changes in dimension, but it's a critical design parameter to remember when engineering components.

Making the Right Choice for Your Goal

Selecting Teflon or a similar material requires matching its primary strengths to your specific challenge.

- If your primary focus is reducing friction: Its incredibly low coefficient of friction makes it the definitive choice for self-lubricating seals, bearings, and industrial liners.

- If your primary focus is chemical resistance: Its inertness is essential for equipment that handles corrosive chemicals, from laboratory vessels to large-scale industrial fuel tanks.

- If your primary focus is biocompatibility: Its non-reactive nature makes it a trusted material for medical implants that must function safely inside the human body.

Ultimately, Teflon's value comes from a rare combination of chemical stability and physical slipperiness that solves critical engineering challenges.

Summary Table:

| Property | Key Characteristic | Primary Benefit |

|---|---|---|

| Chemical Inertness | Strong carbon-fluorine bonds | Resists corrosion from harsh chemicals |

| Low Friction | Extremely low coefficient of friction | Reduces wear on moving parts |

| Anti-Adhesion | Low surface energy | Prevents materials from sticking |

| Heat Resistance | High melting point (327°C / 620°F) | Stable in high-temperature environments |

| Biocompatibility | Non-reactive with human tissue | Ideal for medical implants and devices |

Need High-Performance PTFE Components?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, gaskets, and custom labware—that leverage these exact non-stick, chemically inert, and durable properties.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders. Our expertise ensures your components meet the demanding requirements of your application.

Let's discuss your project requirements. Contact our engineering team today for a quote or to learn more.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability