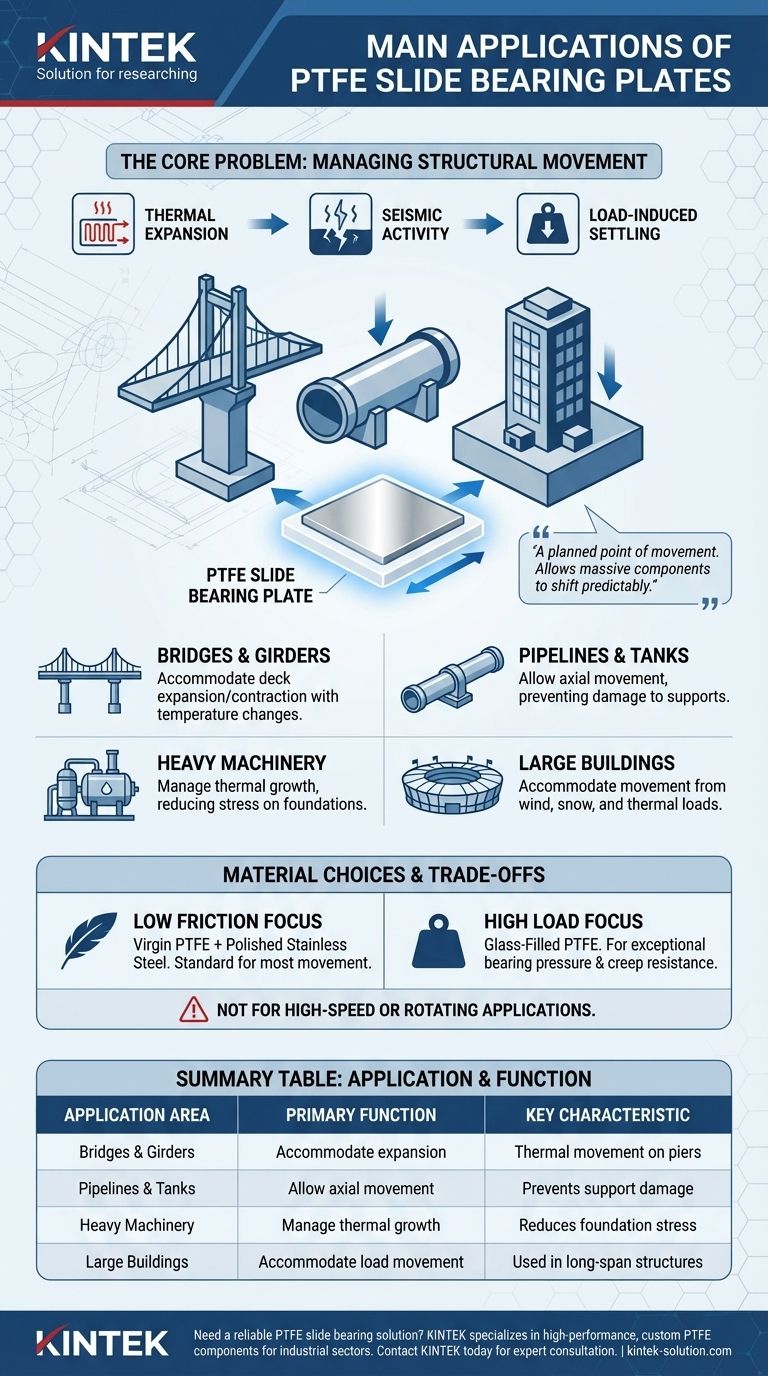

PTFE slide bearing plates are primarily used in large-scale structural and industrial applications where controlled, low-friction movement is essential. Their main function is to safely accommodate the movement of heavy structures like bridge girders, pipelines, and heavy machinery caused by thermal expansion, seismic forces, or load-induced settling.

The core purpose of a PTFE slide bearing plate is not simply to reduce friction, but to act as a planned point of movement. It allows massive, interconnected components to shift predictably and safely, preventing the buildup of destructive internal stresses.

The Core Problem: Managing Structural Movement

Nearly all large structures move. A slide bearing is an engineered solution that isolates a structure from its foundation or from other components, allowing this movement to occur without causing damage.

Thermal Expansion and Contraction

Materials like steel and concrete expand when heated and shrink when cooled. Over the length of a bridge or pipeline, this change can amount to several inches, creating immense force.

PTFE slide plates provide a surface that allows heavy structural elements, like bridge decks or long pipe runs, to slide freely as temperatures fluctuate.

Seismic Activity and Differential Settling

In seismically active regions, buildings and bridges must be able to move with the ground to dissipate energy. Slide bearings can act as a base isolation system.

They also accommodate the slow, uneven settling of a structure's foundation over time, preventing cracks and structural failure.

High Loads and Low Speeds

PTFE is uniquely suited for these applications because it performs best under high pressure and very low speeds.

Its self-lubricating properties mean it provides a consistently low coefficient of friction without requiring maintenance, which is ideal for components that are often inaccessible after construction.

Key Application Areas in Detail

The principle of accommodating slow, high-load movement is applied across several key industries.

Bridges and Girders

The most common application is between a bridge deck's support girders and the concrete piers. The plates allow the deck to expand and contract with daily and seasonal temperature changes.

Pipelines and Tank Farms

Long pipelines, especially in the oil and gas industry, experience significant thermal expansion. Support saddles equipped with PTFE slide plates allow the pipe to move axially without damaging the supports.

Similarly, large storage tanks use these plates to manage thermal movement and foundation settling.

Heavy Machinery and Industrial Equipment

Massive vessels, boilers, or heavy machinery often operate at high temperatures. Slide plates installed at their support points allow for thermal growth without putting stress on the equipment or its foundation.

Large-Scale Architectural Structures

Stadium roofs, convention centers, and other large buildings with long-span steel trusses use PTFE bearings. These plates accommodate movement from thermal changes, wind loads, and even snow loads.

Understanding the Trade-offs and Material Choices

While the concept is simple, material selection is critical for performance and longevity. The bearing is a system, not just a single material.

The Mating Surface is Critical

For the lowest friction, PTFE is almost always paired with a highly polished stainless steel surface. The quality of this mating surface directly impacts the performance of the bearing.

Virgin PTFE vs. Filled Grades

Virgin PTFE offers the lowest coefficient of friction, making it ideal for most standard applications.

However, for structures with exceptionally high bearing pressures, glass-filled PTFE is used. The glass fibers increase the material's compressive strength and resistance to "creep" (slow deformation under load), but at the cost of slightly higher friction.

Not for High-Speed Applications

It is critical to understand that these plates are designed for slow, intermittent movement. They are not suitable for dynamic, high-speed, or rotating applications where traditional roller or ball bearings are required.

Making the Right Choice for Your Goal

Selecting the correct slide bearing plate system depends on the specific forces at play in your project.

- If your primary focus is minimizing friction: A virgin PTFE plate sliding on a polished stainless steel surface is the standard solution for accommodating most structural movement.

- If your primary focus is supporting extreme loads: A filled material like 25% glass-filled PTFE is necessary to prevent material deformation under exceptionally high bearing pressure.

- If your primary focus is a high-temperature environment: Standard PTFE may not be sufficient; specialized materials like graphite slide plates are designed for applications exceeding 500°F (260°C).

By understanding these principles, you can select a slide bearing plate that safely and reliably manages structural forces for the life of your project.

Summary Table:

| Application Area | Primary Function | Key Characteristic |

|---|---|---|

| Bridges & Girders | Accommodate deck expansion/contraction | Manages thermal movement on piers |

| Pipelines & Tanks | Allow axial movement from temperature changes | Prevents damage to supports |

| Heavy Machinery | Manage thermal growth of equipment | Reduces stress on foundations |

| Large Buildings | Accommodate movement from wind/snow loads | Used in long-span structures |

Need a reliable PTFE slide bearing solution for your project?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including slide bearing plates—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require virgin PTFE for minimal friction or glass-filled grades for extreme loads, our precision production ensures your structural movement is managed safely and effectively, from prototype to high-volume orders.

Contact KINTEK today to discuss your specific requirements and receive a expert consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation