At its core, an expanded PTFE (ePTFE) gasket retains the most valued chemical and thermal properties of standard PTFE. You can expect the same exceptional chemical resistance across the full pH range, a very wide operational temperature window, and an extremely low-friction, non-contaminating surface.

The critical takeaway is that ePTFE is not a compromise; it's an enhancement. It takes the superior chemical and thermal stability of PTFE and fundamentally improves its mechanical properties as a sealing material, solving common gasket-related failures like creep and cold flow.

The Shared Foundation: Core PTFE Characteristics

The expansion process transforms PTFE's physical structure from a rigid solid into a soft, fibrous material, but it does not alter its fundamental molecular composition. This means the core benefits are fully preserved.

Unmatched Chemical Inertness

An ePTFE gasket is just as chemically resistant as a standard PTFE one. It remains stable when exposed to the most aggressive media across the 0-14 pH range.

The only common exceptions are highly reactive substances like molten alkali metals and elemental fluorine.

Broad Temperature Stability

The ability to perform reliably in extreme temperatures is a hallmark of PTFE that ePTFE fully retains.

These gaskets operate effectively in a wide range, from cryogenic conditions around -200°C (-328°F) up to continuous service temperatures of 260°C (500°F) or higher.

Low-Friction, Non-Contaminating Surface

Like its solid counterpart, ePTFE is non-wetting, odorless, and non-contaminating. This makes it an ideal clean sealing solution for sensitive industries like food, beverage, and pharmaceuticals.

It also keeps PTFE's characteristically low coefficient of friction and excellent electrical insulation properties.

The "Expansion" Advantage: How ePTFE Improves Sealing Performance

While the chemical properties remain the same, the physical expansion process creates a multidirectional fibrous structure that gives ePTFE gaskets a significant mechanical advantage over solid PTFE.

Overcoming Creep and Cold Flow

Standard PTFE gaskets can be susceptible to creep and cold flow, where the material slowly deforms under pressure and heat, leading to a loss of bolt load and potential leaks.

The interlocking fiber structure of ePTFE fundamentally resists this tendency, ensuring a more reliable and long-lasting seal that maintains its integrity over time.

Superior Conformability and Flexibility

ePTFE is highly compressible and flexible. This allows it to conform easily to rough, pitted, or irregular flange surfaces where a rigid gasket would fail.

This softness also makes it an excellent choice for fragile equipment, such as glass-lined steel or plastic flanges, as it requires less bolt torque to create an effective seal.

Enhanced Pressure Resistance

The fibrous structure that resists creep also gives ePTFE gaskets the toughness to handle much higher internal pressures.

While a pure PTFE gasket might be rated for pressures around 5 MPa (~725 psi), an ePTFE gasket can often seal pressures well over 3000 psi, depending on the flange design and application.

Understanding the Trade-offs

The choice between standard PTFE and ePTFE is less about good versus bad and more about form versus function. They are different physical forms of the same base material, each suited for different tasks.

Gasket vs. Machined Part

ePTFE excels as a soft, conformable gasket. Its purpose is to compress and fill imperfections between two surfaces.

Standard PTFE is a rigid plastic. It is the correct choice for applications requiring a solid, structural component, such as a machined spacer, an insulator, or a valve seat. Using it as a gasket for anything but perfectly flat, rigid flanges invites problems like cold flow.

Cost and Complexity

Generally, the advanced processing required to create ePTFE makes it a more premium material than standard PTFE stock shapes. The trade-off is paying for superior sealing reliability and a wider application window.

Making the Right Choice for Your Application

Selecting the correct material requires matching its physical form to your primary engineering goal.

- If your primary focus is sealing aggressive chemicals in a high-temperature flange: ePTFE is the superior choice because it offers PTFE's chemical resistance combined with robust mechanical stability against creep.

- If your primary focus is sealing a fragile or uneven flange surface: ePTFE is the definitive solution due to its high compressibility and ability to conform with minimal bolt load.

- If your primary focus is creating a rigid, load-bearing component or insulator: Standard, solid PTFE is the correct material, as it is designed for structural rather than compressive sealing applications.

By understanding this distinction, you can leverage the exceptional properties of PTFE in the correct physical form for your specific challenge.

Summary Table:

| Property | PTFE | ePTFE Gaskets |

|---|---|---|

| Chemical Resistance | Excellent (0-14 pH) | Excellent (0-14 pH) |

| Temperature Range | -200°C to 260°C+ | -200°C to 260°C+ |

| Low-Friction Surface | Yes | Yes |

| Resistance to Creep/Cold Flow | Low | High |

| Conformability & Flexibility | Low (Rigid) | High |

| Pressure Resistance (Typical) | ~5 MPa (~725 psi) | >20 MPa (>3000 psi) |

Leverage the Superior Sealing Performance of PTFE

Choosing the right PTFE material form is critical for your application's success. KINTEK specializes in manufacturing high-performance PTFE and ePTFE components, including custom gaskets, seals, and labware.

We help engineers and procurement specialists in the semiconductor, medical, laboratory, and industrial sectors by providing:

- Expert Material Selection: Guidance on whether standard PTFE or enhanced ePTFE is the right choice for your specific chemical, thermal, and mechanical requirements.

- Precision Manufacturing: Components produced to exact specifications for reliable performance.

- Custom Fabrication: From initial prototypes to high-volume production runs.

Ensure leak-free operation and long-term reliability in your most demanding applications.

Contact KINTEK today to discuss your project requirements and get a quote.

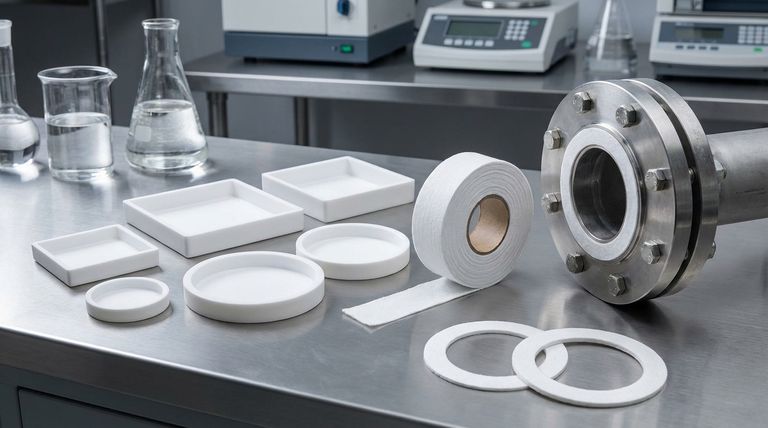

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes Teflon plastic sheets versatile across industries? The Ultimate High-Performance Solution

- What temperature ranges can FEP and PTFE encapsulated O-rings withstand? A Guide to Extreme Environment Sealing

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What is the PH range and temperature tolerance of pure PTFE gaskets? Master Extreme Chemical and Thermal Sealing

- What precautions should be taken when handling PTFE gaskets? Ensure Longevity & Performance

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What are some common PTFE-based sealing components and their functions? Discover High-Performance Sealing Solutions

- What is the temperature range that PTFE instrumentation tube fittings can withstand? A Guide to Extreme Thermal Performance