While incredibly robust, the primary disadvantages of bronze bushings are their consistent need for lubrication to prevent failure and their potential to be noisy, especially when lubrication is inadequate. These characteristics stem from their metal-on-metal design, which offers high strength at the cost of higher friction compared to other bearing types.

The perceived "disadvantages" of bronze bushings are not flaws, but inherent trade-offs. Understanding these trade-offs is the key to knowing when they are the ideal engineering choice versus when an alternative like a plastic or ball bearing is more appropriate.

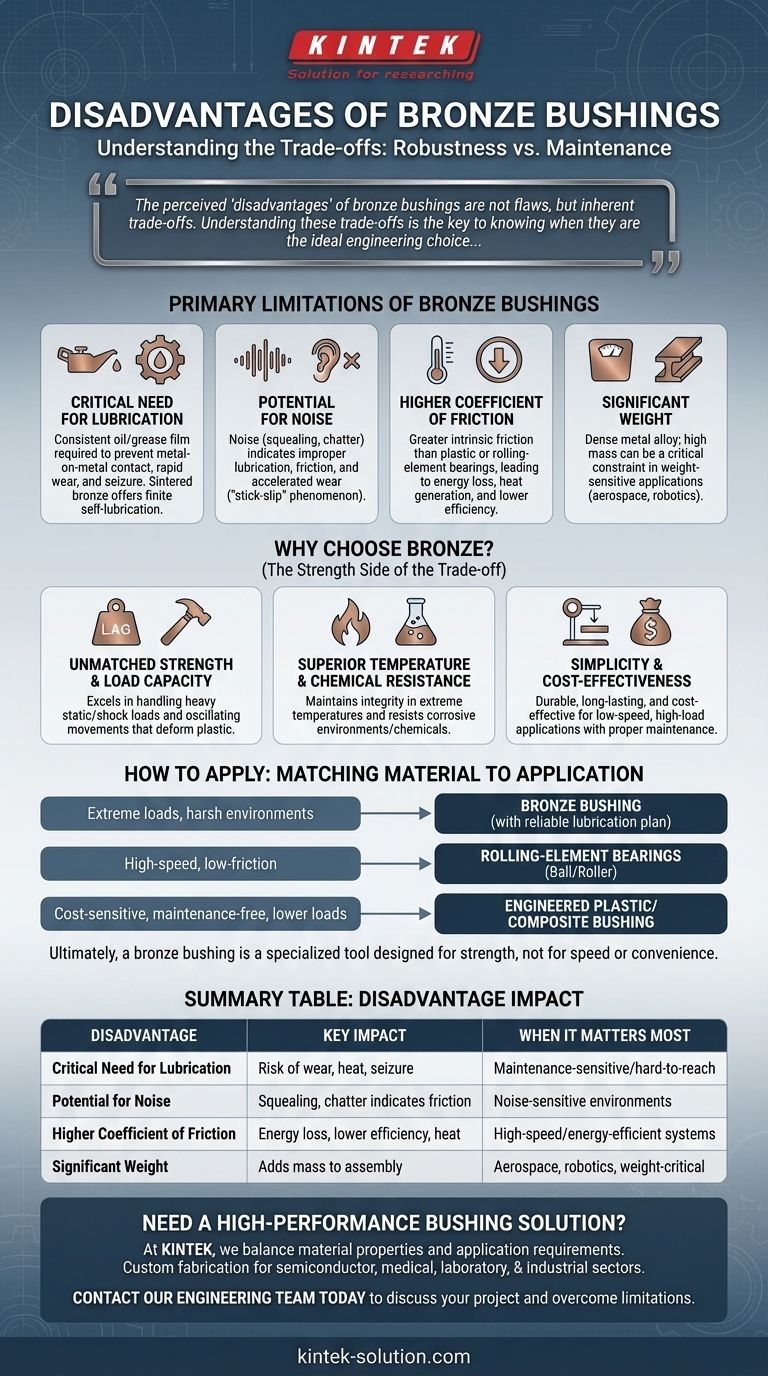

The Primary Limitations of Bronze Bushings

Bronze bushings are a fundamental machine component, but their effectiveness is entirely dependent on their operating environment and maintenance. Their limitations are most apparent when misapplied.

The Critical Need for Lubrication

Solid bronze bushings require a consistent film of lubricant (oil or grease) to separate the bushing surface from the rotating shaft. Without it, direct metal-on-metal contact occurs, leading to rapid wear, high heat generation, and eventual seizure of the joint.

Some variants, like sintered bronze bushings, are oil-impregnated and considered "self-lubricating." However, this internal lubrication is finite and can be depleted over time, especially under high heat or speed, eventually requiring supplemental lubrication.

Potential for Noise

The noise associated with bronze bushings is almost always a symptom of improper lubrication. A phenomenon known as stick-slip can occur as the surfaces momentarily weld and break apart, creating chatter or squealing. This is a clear indicator that friction is too high and wear is accelerating.

Higher Coefficient of Friction

Compared to polymer (plastic) bushings or rolling-element bearings (ball bearings), bronze has a higher intrinsic coefficient of friction. This translates directly to a loss of energy, which manifests as heat. In high-speed or efficiency-critical systems, this energy loss is a significant drawback.

Significant Weight

Bronze is a dense metal alloy. In applications where weight is a critical design constraint, such as in aerospace or performance robotics, the high mass of bronze bushings can be a distinct disadvantage compared to lighter alternatives like engineered plastics.

Understanding the Trade-offs: Why Choose Bronze?

The limitations of bronze bushings are directly tied to their greatest strengths. They are chosen specifically for applications where other bearing types would fail.

Unmatched Strength and Load Capacity

The core advantage of bronze is its high compressive strength and load-bearing capacity. It excels in handling heavy static loads, shock loads, and oscillating movements that would deform or destroy a plastic bushing.

Superior Temperature and Chemical Resistance

Bronze maintains its structural integrity and performance at temperatures far exceeding the limits of most polymers. It is also highly resistant to a wide range of chemicals, solvents, and corrosive environments, making it ideal for heavy industrial or outdoor machinery.

Simplicity and Cost-Effectiveness

For low-speed, high-load applications, a simple bronze bushing is an extremely durable and cost-effective solution. Its design is simple, and its lifespan can be exceptionally long with a proper maintenance schedule.

How to Apply This to Your Project

Choosing the correct bearing requires matching the material's properties to the specific demands of your application.

- If your primary focus is handling extreme loads and ensuring durability in harsh environments: A bronze bushing is likely the superior choice, provided you can implement a reliable lubrication plan.

- If your primary focus is high-speed rotation and low-friction efficiency: You must look to rolling-element bearings, such as ball or roller bearings.

- If your primary focus is cost-sensitive, maintenance-free operation at lower loads: An engineered plastic or composite bushing is often the more practical solution.

Ultimately, a bronze bushing is a specialized tool designed for strength, not for speed or convenience.

Summary Table:

| Disadvantage | Key Impact | When It Matters Most |

|---|---|---|

| Critical Need for Lubrication | Risk of wear, heat, and seizure without it. | In maintenance-sensitive or hard-to-reach applications. |

| Potential for Noise | Squealing or chatter indicates high friction. | In noise-sensitive environments or equipment. |

| Higher Coefficient of Friction | Energy loss, lower efficiency, heat generation. | In high-speed or energy-efficient systems. |

| Significant Weight | Adds mass to the assembly. | In aerospace, robotics, or weight-critical designs. |

Need a high-performance bushing solution tailored to your specific demands?

At KINTEK, we understand that the right component is a balance of material properties and application requirements. Whether your priority is handling extreme loads in harsh environments or achieving maintenance-free operation, our expertise in custom fabrication can help.

We manufacture precision components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize durability and performance.

Contact our engineering team today to discuss your project and discover how we can provide a solution that overcomes the limitations of standard bushings.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts