The primary advantages of PTFE lined butterfly valves are their exceptional chemical resistance against corrosive media, their ability to operate across a very wide temperature range, and their superior, leak-proof sealing performance. These characteristics make them a highly reliable and cost-effective solution for demanding industrial applications where standard valves would quickly fail.

The core value of a PTFE lined butterfly valve is its ability to provide the performance of an expensive, exotic alloy valve at a fraction of the cost. The inert PTFE liner protects a standard valve body, making it a specialized tool for controlling aggressive fluids in challenging environments.

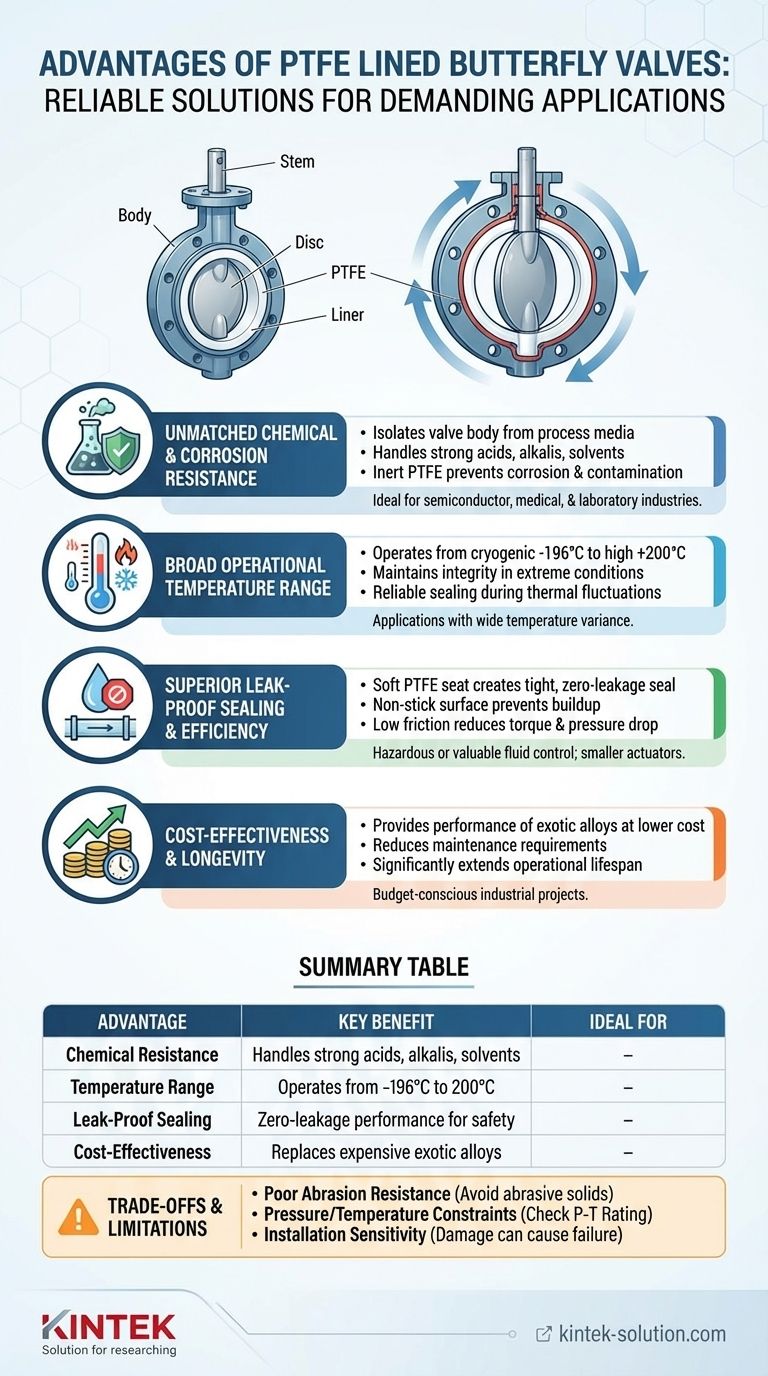

The Core Strengths of a PTFE Lining

The Polytetrafluoroethylene (PTFE) liner is not merely a coating; it is a substantial, non-porous barrier that fundamentally changes the valve's capabilities. It isolates the valve's structural body from the process media.

Unmatched Chemical and Corrosion Resistance

PTFE is one of the most chemically inert materials known. This property is its most significant advantage.

This makes the valve suitable for handling a vast array of strong acids, alkalis, solvents, and other corrosive substances that would rapidly degrade even high-grade stainless steel.

By protecting the valve body (typically made of cast iron or carbon steel), the liner prevents corrosion and contamination of the process media.

Broad Operational Temperature Range

PTFE maintains its integrity and performance across an impressive spectrum of temperatures.

It can handle cryogenic applications, remaining soft and functional at temperatures as low as -196°C (-320°F).

It also excels at high temperatures, with continuous service ratings often reaching 200°C (392°F) and sometimes higher for short durations. This thermal stability ensures reliable sealing even when process temperatures fluctuate.

Superior Sealing and Leak Prevention

The design of these valves, combined with the properties of PTFE, results in an extremely reliable seal.

The soft, flexible nature of the PTFE seat allows it to create a tight shut-off against the disc, often achieving zero-leakage performance.

This is critical in applications involving hazardous or valuable chemicals, where any leakage is unacceptable for safety and financial reasons.

Enhanced Flow Efficiency

The surface of PTFE is extremely smooth and has a very low coefficient of friction, a property famously used in non-stick cookware.

This non-stick characteristic prevents media from building up on the valve's internal surfaces, ensuring a smooth and consistent flow while minimizing pressure drop.

It also reduces the torque required to open and close the valve, allowing for smaller, more energy-efficient actuators.

Practical Advantages in Operation

Beyond its core material properties, a PTFE lining delivers tangible benefits in terms of reliability and total cost of ownership.

Reduced Maintenance and Extended Lifespan

Because the liner resists both chemical attack and media buildup, the valve's internal components are shielded from wear and tear.

This directly translates to reduced maintenance requirements and a significantly longer operational lifespan compared to unlined valves in the same service.

Cost-Effectiveness in Demanding Roles

PTFE lined valves offer a powerful economic advantage.

They allow the use of a lower-cost valve body material (like ductile iron) in services that would otherwise demand valves constructed entirely from expensive, exotic alloys like Hastelloy or Titanium.

This provides the necessary chemical resistance without the prohibitive cost of an all-alloy body.

Understanding the Trade-offs

While highly capable, PTFE lined valves are not a universal solution. Understanding their limitations is key to successful application.

Susceptibility to Abrasives

PTFE is a relatively soft material. It provides excellent corrosion resistance but poor abrasion resistance.

Using these valves in services with hard, abrasive particles or slurries can quickly damage the liner, leading to seal failure and corrosion of the valve body.

Pressure and Temperature Constraints

While the temperature range is wide, it is not unlimited. The mechanical strength of PTFE decreases as temperature increases.

Therefore, every valve has a specific pressure-temperature (P-T) rating. High pressures combined with high temperatures can cause the PTFE to deform, compromising the seal. Always operate within the manufacturer's specified P-T curve.

Installation Sensitivity

The integrity of the liner is paramount. Any scratch, gouge, or damage to the PTFE surface during installation can create a pathway for corrosive media to attack the valve body.

Proper handling and careful installation procedures are absolutely critical to ensure the long-term reliability of the valve.

Making the Right Choice for Your Goal

Selecting the correct valve depends entirely on the demands of your specific process.

- If your primary focus is handling highly corrosive media: A PTFE lined butterfly valve is an ideal and cost-effective choice, providing protection against a wide range of aggressive chemicals.

- If your application involves a wide temperature variance: The exceptional thermal stability of PTFE makes it a strong contender for both very low and moderately high-temperature services.

- If your media contains abrasive solids or is a high-pressure slurry: You should exercise caution and strongly consider a more robust alternative, such as a metal-seated or rubber-lined valve designed for abrasion.

- If your priority is zero-leakage sealing in a chemical process: The reliable, tight shut-off of a PTFE lined valve offers a high degree of safety and performance.

By understanding both the powerful advantages and the specific limitations of PTFE, you can confidently specify the right valve for your most demanding applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Handles strong acids, alkalis, and solvents | Semiconductor, medical, and laboratory industries |

| Temperature Range | Operates from -196°C to 200°C | Applications with thermal fluctuations |

| Leak-Proof Sealing | Zero-leakage performance for safety | Hazardous or valuable fluid control |

| Cost-Effectiveness | Replaces expensive exotic alloys | Budget-conscious industrial projects |

Need a reliable PTFE lined butterfly valve for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services ensure you get the exact valve solution, from prototypes to high-volume orders, without compromising on durability or chemical resistance.

Let us help you enhance your process efficiency and safety. Contact us today for a tailored quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability