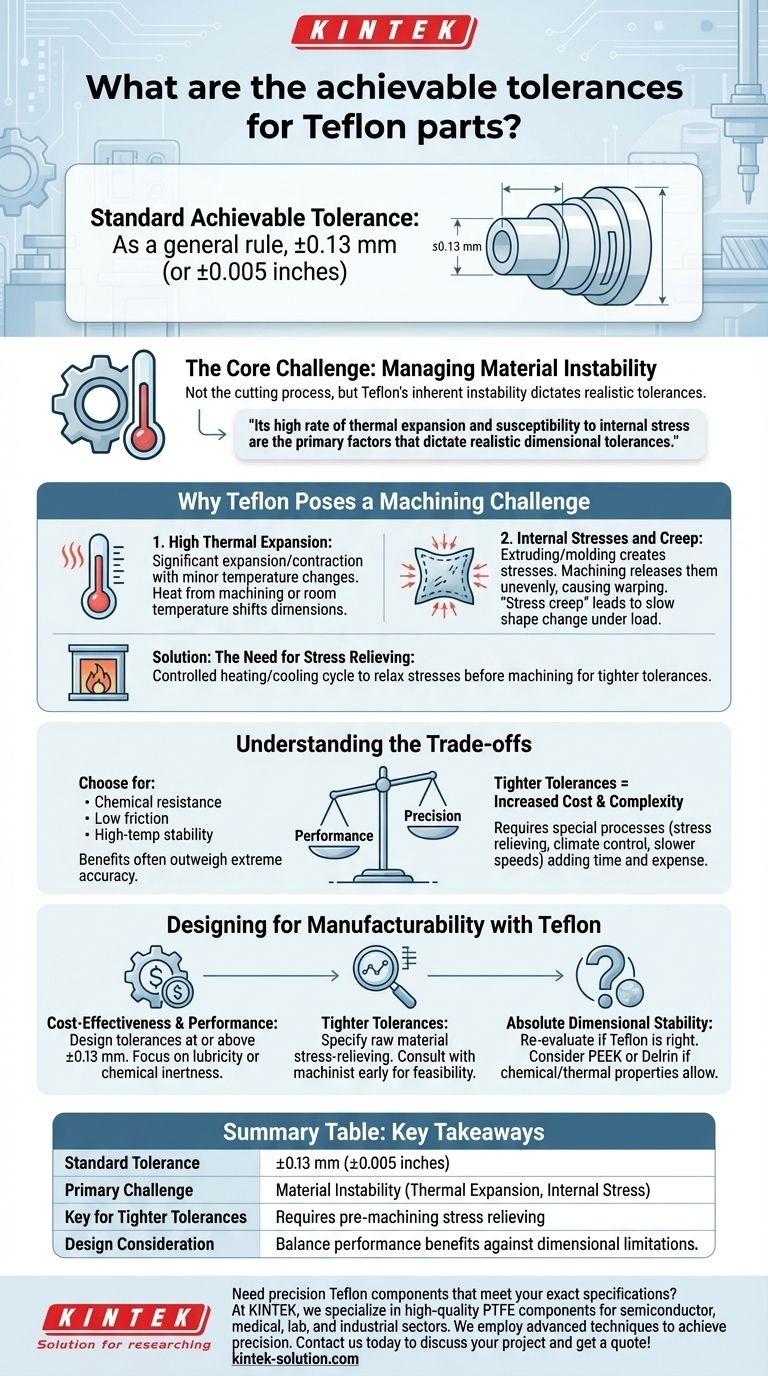

As a general rule, the standard achievable tolerance for machined Teflon (PTFE) parts is approximately ±0.13 mm (or ±0.005 inches). Attempting to hold dimensions tighter than this is challenging due to Teflon's inherent material properties, which cause it to move and change shape both during and after the machining process. Achieving higher precision is possible but requires special handling and pre-treatment of the material.

The core challenge in machining Teflon is not the cutting process itself, but managing the material's instability. Its high rate of thermal expansion and susceptibility to internal stress are the primary factors that dictate realistic dimensional tolerances.

Why Teflon Poses a Machining Challenge

Understanding why Teflon is difficult to machine is key to designing parts that are both functional and manufacturable. The material's unique characteristics present several hurdles for precision work.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. This means it expands and contracts significantly with even minor changes in temperature.

The heat generated during machining, or even a change in room temperature, can cause the part's dimensions to shift, making it difficult to hold tight tolerances consistently.

Internal Stresses and Creep

The process of manufacturing raw Teflon stock (extruding or molding) induces internal stresses. When material is machined away, these stresses can be released unevenly, causing the part to warp or deform.

Furthermore, Teflon is susceptible to stress creep, meaning it can slowly change shape over time if under load. This can affect long-term dimensional stability.

The Need for Stress Relieving

To achieve tolerances tighter than the standard ±0.13 mm, the raw material must often be stress-relieved before machining.

This involves a controlled heating and cooling cycle to relax the internal stresses, creating a more stable workpiece that is less likely to deform after machining.

Understanding the Trade-offs

Engineers choose Teflon for its exceptional properties, not its ease of machining. This creates a natural trade-off between performance characteristics and dimensional precision.

Performance vs. Precision

You specify Teflon for its outstanding chemical resistance, low coefficient of friction, and high-temperature stability.

These benefits often outweigh the need for the extreme dimensional accuracy you might achieve with materials like aluminum or steel. The design must accommodate Teflon's inherent dimensional limitations.

The Cost of Tighter Tolerances

Requesting tolerances beyond the standard capability of Teflon directly translates to increased cost and complexity.

Achieving higher precision requires special processes like stress relieving, climate-controlled machining environments, and slower cutting speeds. These steps add significant time and expense to the manufacturing process.

Designing for Manufacturability with Teflon

To ensure a successful outcome, your design approach must align with the material's physical realities.

- If your primary focus is cost-effectiveness and performance: Design your part with tolerances at or above the standard ±0.13 mm and focus on features that leverage Teflon's key strengths, like its lubricity or chemical inertness.

- If your design genuinely demands tighter tolerances: Specify that the raw material must be stress-relieved before machining and consult with your machinist early in the design process to discuss feasibility.

- If absolute dimensional stability is the top priority: Re-evaluate if Teflon is the right choice. Materials like PEEK or Delrin (Acetal) may offer better stability if your application can accommodate their different chemical and thermal properties.

Ultimately, successful design with Teflon comes from embracing its strengths while respecting its physical limitations.

Summary Table:

| Aspect | Key Information |

|---|---|

| Standard Tolerance | ±0.13 mm (±0.005 inches) |

| Primary Challenge | Material instability (thermal expansion, internal stress) |

| Key for Tighter Tolerances | Requires pre-machining stress relieving |

| Design Consideration | Balance performance benefits against dimensional limitations |

Need precision Teflon components that meet your exact specifications?

At KINTEK, we specialize in manufacturing high-quality PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of machining Teflon and employ advanced techniques, including stress relieving and controlled environments, to achieve the precision your application demands.

Let us help you navigate the trade-offs between material performance and dimensional stability. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts are manufactured to the highest standards.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications