In bearing technology, Polytetrafluoroethylene (PTFE), commonly known by the trade name Teflon, is used to create maintenance-free sliding bearings, low-friction coatings, seals, and gaskets. Its value comes from a unique combination of extremely low friction, chemical inertness, and a wide operating temperature range, making it ideal for specialized applications where traditional lubricated metal bearings would fail.

The core reason for using Teflon in bearings is not just its non-stick quality, but its ability to provide consistent, self-lubricating performance under conditions—such as chemical exposure, extreme temperatures, or the need for clean, oil-free operation—that are hostile to other materials.

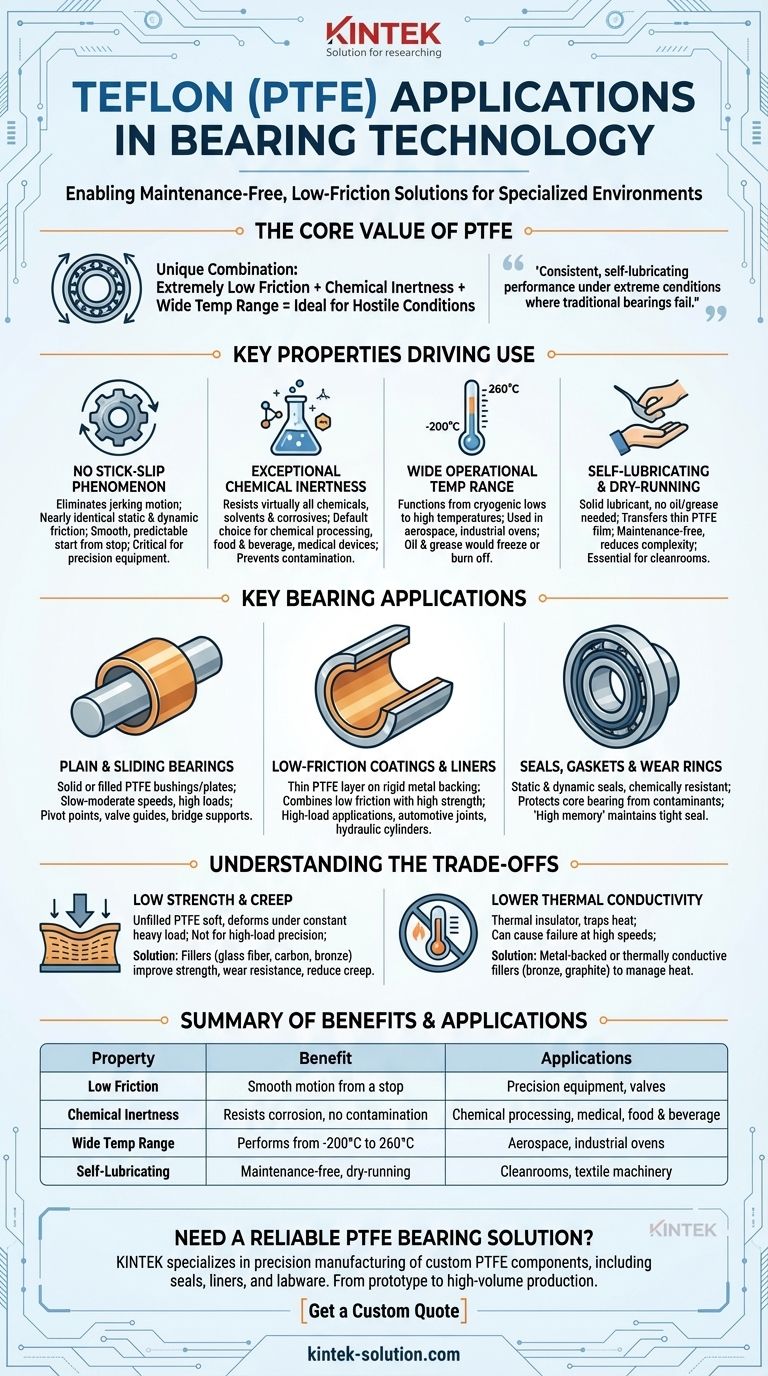

The Core Properties Driving Teflon's Use in Bearings

To understand its applications, we must first look at the material properties that make PTFE so effective in bearing systems. These properties work in concert to solve specific engineering challenges.

The 'No Stick-Slip' Phenomenon

Stick-slip is the jerking motion that occurs at very low speeds when the static friction is significantly higher than the dynamic friction.

PTFE has one of the lowest coefficients of friction of any solid material. Crucially, its static and dynamic coefficients of friction are nearly identical. This eliminates stick-slip, ensuring smooth, predictable motion from a complete stop, which is critical in precision equipment.

Exceptional Chemical Inertness

PTFE is almost entirely inert, resisting virtually all industrial chemicals, solvents, and corrosives.

This property makes PTFE bearings the default choice for equipment used in chemical processing, food and beverage production, and medical devices, where contamination from lubricants or bearing degradation is unacceptable.

Wide Operational Temperature Range

PTFE maintains its key properties over an exceptionally broad temperature spectrum, from cryogenic lows (-200°C) up to high temperatures (260°C).

This allows PTFE-based bearings to function in extreme environments like aerospace applications or industrial ovens where oils and greases would either freeze or burn off.

Self-Lubricating and Dry-Running Capability

PTFE functions as a solid lubricant, requiring no external oil or grease. During initial operation, it transfers a thin film of material to the mating surface, creating a highly effective PTFE-on-PTFE sliding interface.

This characteristic is essential for creating maintenance-free bearing systems, reducing complexity and lifetime cost. It also prevents contamination from lubricants, a vital benefit in medical, food, and textile applications.

Key Applications in Bearing Systems

These properties translate directly into specific components used within and around bearing assemblies.

Plain and Sliding Bearings

These are simple bushings or plates made from solid or filled PTFE. A shaft or sliding element moves directly against the PTFE surface.

They are best suited for applications with slow-to-moderate speeds and high loads, such as pivot points on heavy equipment, valve guides, and architectural support pads for bridges.

Low-Friction Coatings and Liners

In this design, a thin layer of PTFE is bonded to a rigid metal backing (like steel or bronze). This creates a composite bearing that combines the low friction of PTFE with the high mechanical strength and heat dissipation of metal.

This is the most common form for high-performance applications, offering excellent load capacity and dimensional stability for everything from automotive suspension joints to industrial hydraulic cylinders.

Seals, Gaskets, and Wear Rings

Because it is both malleable and chemically resistant, PTFE is widely used for static and dynamic seals within bearing assemblies.

These components protect the core bearing from contaminants like dust and moisture while providing a low-friction surface for rotating or reciprocating parts. Its "high memory" allows it to maintain a tight seal even after compression.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Understanding its limitations is critical for proper application.

Low Mechanical Strength and Creep

Unfilled, pure PTFE is a relatively soft material. Under a constant, heavy load, it can slowly deform over time in a process known as creep.

This makes pure PTFE unsuitable for high-load precision applications where dimensional stability is paramount.

The Role of Fillers

To counteract its softness, PTFE is often blended with fillers like glass fiber, carbon, bronze, or graphite. This creates a "filled PTFE" composite.

Fillers dramatically improve wear resistance, reduce creep, and increase load-bearing capacity. For example, bronze-filled PTFE offers higher strength, while carbon-filled PTFE provides better conductivity to dissipate heat.

Lower Thermal Conductivity

Pure PTFE is a thermal insulator, meaning it does not dissipate heat well. In high-speed applications, friction can generate heat that gets trapped, potentially causing the bearing to fail.

Metal-backed bearings or the use of thermally conductive fillers (like bronze or graphite) are necessary to manage heat in applications involving higher speeds.

Making the Right Choice for Your Goal

Selecting the correct PTFE solution depends entirely on the demands of your application.

- If your primary focus is maintenance-free operation in a clean environment: A pure or filled PTFE plain bearing is an excellent choice for low-speed, moderate-load applications like those in food processing or medical devices.

- If your primary focus is supporting high loads with structural rigidity: A metal-backed bearing with a PTFE liner provides the best of both worlds, combining the strength of steel with the self-lubricating surface of PTFE.

- If your primary focus is extreme chemical or temperature resistance: A PTFE-based bearing, either solid or lined, is often the only viable choice, outperforming nearly all traditional metal bearings in corrosive or high-temperature settings.

By understanding these properties and trade-offs, you can confidently specify a Teflon-based solution precisely where it delivers the most engineering value.

Summary Table:

| Property | Benefit for Bearings | Common Applications |

|---|---|---|

| Low Friction (No Stick-Slip) | Smooth motion from a stop | Precision equipment, valves |

| Chemical Inertness | Resists corrosion, no contamination | Chemical processing, medical, food & beverage |

| Wide Temperature Range | Performs from -200°C to 260°C | Aerospace, industrial ovens |

| Self-Lubricating | Maintenance-free, dry-running | Cleanrooms, textile machinery |

Need a reliable PTFE bearing solution for your specialized application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you require a maintenance-free sliding bearing for a medical device, a chemically inert seal for a semiconductor tool, or a high-temperature liner for an industrial process, we can fabricate the perfect solution—from prototype to high-volume production.

Contact us today to discuss how our expertise in PTFE can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are PTFE O-rings and their key characteristics? Solve Extreme Chemical & Thermal Sealing Challenges

- What should be placed between a shirt and a heat press? Protect Your Gear with the Right Barrier

- What is creep in PTFE gasket sheets and how can it be mitigated? Prevent Seal Failure and Leaks

- What are the advantages of spring-energized PTFE seals? Achieve Superior Sealing in Extreme Conditions

- How does the chemical resistance of PTFE oil seals benefit their use? Ensure Leak-Free Reliability in Harsh Chemical Environments

- Which industries commonly use PTFE expansion bellows and why? Essential for Corrosion and Contamination Control

- How are PTFE Teflon washers used in the automotive industry? Essential for High-Temp, Corrosive Seals

- How does the versatility of PTFE gaskets and sheets benefit users? Achieve a Perfect Seal for Any Application