At its core, a PTFE lined butterfly valve is an industrial valve designed for one primary purpose: to safely control the flow of highly corrosive or high-purity fluids. It combines the simple, quick-action mechanism of a standard butterfly valve with a protective internal layer of Polytetrafluoroethylene (PTFE), effectively isolating the valve's metal body from aggressive media.

The critical takeaway is that the PTFE liner transforms the valve from a general-purpose component into a specialized, cost-effective solution for handling harsh chemicals. It delivers the chemical resistance of expensive exotic alloys without the associated high cost.

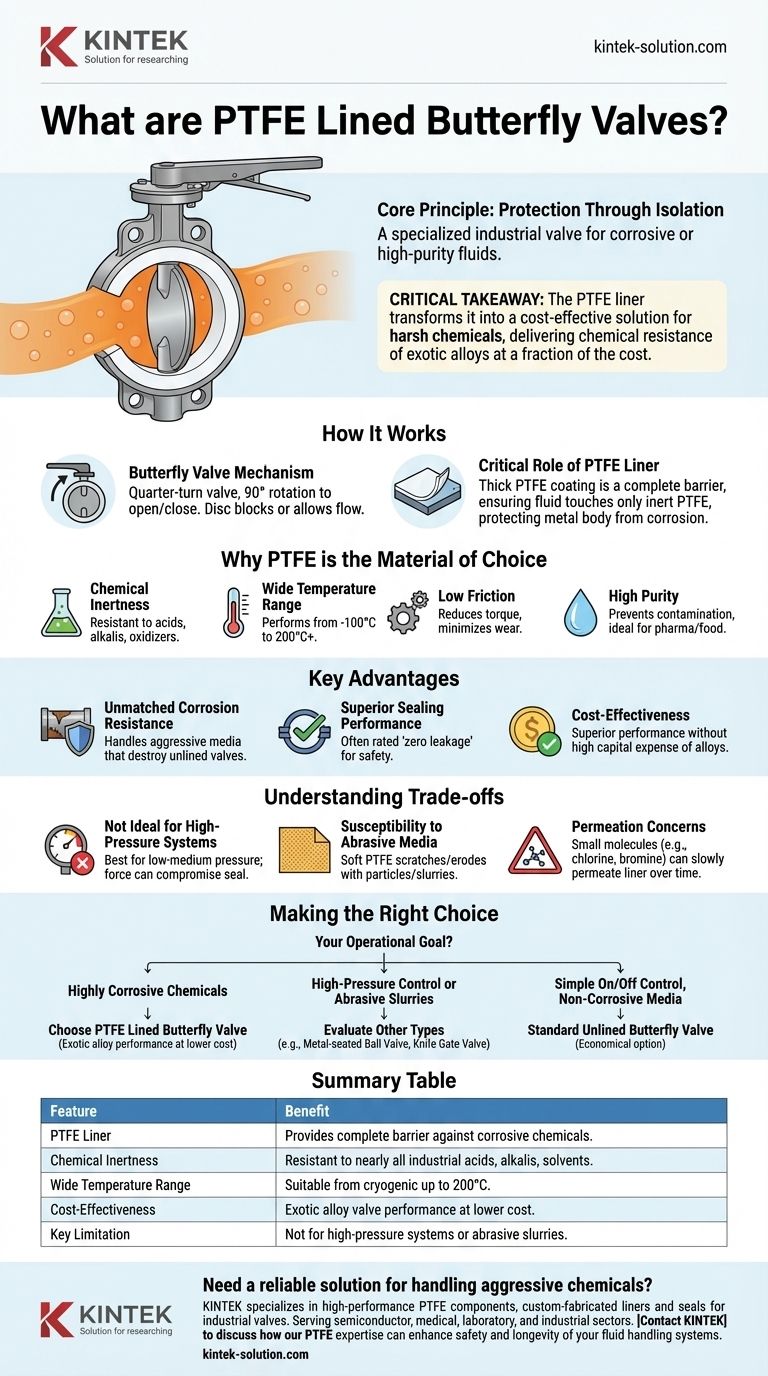

The Core Principle: Protection Through Isolation

To understand the value of this design, it's important to grasp how its two main parts work together to solve a difficult industrial challenge.

How a Butterfly Valve Works

A butterfly valve is a quarter-turn valve, meaning it goes from fully open to fully closed in a 90-degree turn of the handle.

Inside the valve body, a metal disc is mounted on a central stem. When the valve is open, the disc is parallel to the flow, offering minimal resistance. To close it, the disc rotates to block the passageway, sealing against a seat.

The Critical Role of the PTFE Liner

The key innovation is the PTFE liner, which is a thick, non-reactive coating molded to the entire interior surface of the valve body.

This liner acts as a complete barrier, ensuring that the fluid passing through the valve only ever touches the inert PTFE material. This protects the structural metal of the valve (typically cast iron or carbon steel) from corrosion.

Why PTFE is the Material of Choice

PTFE, widely known by the brand name Teflon, is chosen for its unique combination of properties that make it ideal for demanding industrial environments.

- Chemical Inertness: It is resistant to nearly all industrial chemicals, including strong acids, alkalis, and oxidizers.

- Wide Temperature Range: It performs reliably in extreme conditions, from cryogenic temperatures as low as -100°C up to high temperatures of 200°C or more.

- Low Friction: The material has an extremely low coefficient of friction, which means the valve disc can turn easily, reducing the torque required for operation and minimizing wear.

- High Purity: PTFE is inherently a pure material, preventing contamination of the media flowing through it, which is essential in pharmaceutical or food processing applications.

Key Advantages in Industrial Applications

Choosing a PTFE lined valve over alternatives is a strategic decision driven by several distinct benefits.

Unmatched Corrosion Resistance

The primary advantage is the ability to handle aggressive media that would quickly destroy unlined metal valves. This eliminates the need for valves constructed entirely from expensive materials like stainless steel or exotic alloys.

Superior Sealing Performance

The design allows for a tight, reliable seal. Many PTFE lined butterfly valves are rated for "zero leakage," which is critical for ensuring safety and preventing the release of hazardous fluids into the environment.

Cost-Effectiveness

For corrosive applications at normal temperatures and pressures, these valves offer superior cost performance. They provide the necessary chemical resistance without the high capital expense of alloy-based valves, also reducing long-term maintenance and replacement costs.

Understanding the Trade-offs

While highly effective, these valves are not a universal solution. Understanding their limitations is key to using them correctly.

Not Ideal for High-Pressure Systems

Butterfly valves, in general, are best suited for low-to-medium pressure applications. In high-pressure systems, the force on the disc can make it difficult to operate and can compromise the seal.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. These valves excel with corrosive liquids and gases but are not recommended for services containing abrasive particles or slurries, which can scratch or erode the liner and lead to premature failure.

Permeation Concerns with Certain Chemicals

While chemically resistant, very small molecules (like chlorine or bromine) can sometimes slowly permeate the PTFE liner over time, especially at high temperatures. This is a specific consideration for highly specialized applications.

Making the Right Choice for Your System

Selecting the correct valve requires matching its capabilities to your specific operational goal.

- If your primary focus is handling highly corrosive chemicals: A PTFE lined butterfly valve offers the performance of an exotic alloy valve at a fraction of the cost, making it the default choice.

- If your primary focus is high-pressure control or abrasive slurries: You should evaluate other valve types, such as a metal-seated ball valve or a knife gate valve, as the PTFE liner is likely to be a point of failure.

- If your primary focus is simple on/off control for non-corrosive media (like water or air): A standard, unlined butterfly valve with a rubber seat is a more economical and perfectly suitable option.

Ultimately, choosing a PTFE lined butterfly valve is a strategic decision to gain superior chemical resistance and safety in applications where standard materials would quickly fail.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Liner | Provides a complete barrier against corrosive chemicals, protecting the metal valve body. |

| Chemical Inertness | Resistant to nearly all industrial acids, alkalis, and solvents. |

| Wide Temperature Range | Suitable for use from cryogenic temperatures up to 200°C. |

| Cost-Effectiveness | Offers the performance of exotic alloy valves at a significantly lower cost. |

| Key Limitation | Not recommended for high-pressure systems or abrasive slurries. |

Need a reliable solution for handling aggressive chemicals?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-fabricated liners and seals for industrial valves. Our expertise ensures your equipment is protected against even the most corrosive media.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom solutions from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE expertise can enhance the safety and longevity of your fluid handling systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Can machined PTFE parts be customized? Achieve Precision Solutions for Demanding Applications

- What is a potential downside of PTFE bushings under heavy loads? Prevent Deformation with the Right Material

- Why is hardness important for mating parts in PTFE seals? Extend Seal Life and Prevent Failure

- What are the properties of standard Polytetrafluoroethylene (PTFE)? The Ultimate Guide to Its Strengths & Limitations

- What is PTFE packing and what is its primary use? The Ultimate Sealing Solution for Harsh Environments

- What are some examples of specialty PTFE formulations and their benefits? Enhance Performance with Filled PTFE

- What makes PTFE gaskets and sheets ideal for chemical and pharmaceutical industries? Achieve Uncompromising Purity and Safety

- How do PTFE rotary shaft seals perform in high-speed applications? Master High-Speed Sealing with Low Friction