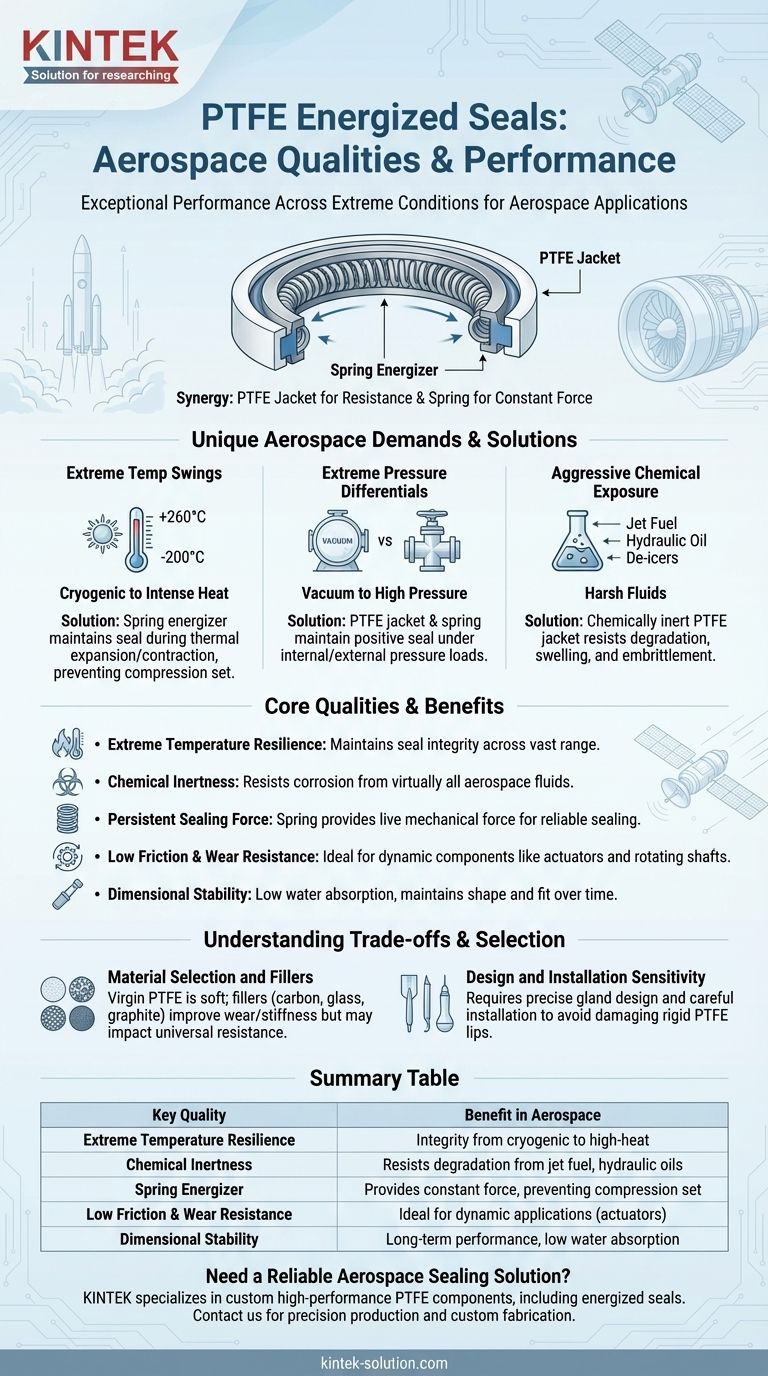

In addition to their foundational properties, PTFE energized seals are uniquely suited for aerospace applications due to their exceptional performance across extreme temperature and pressure ranges, their near-universal chemical inertness, and the persistent sealing force provided by the internal spring energizer. These characteristics ensure seal integrity in the volatile conditions found in aircraft engines, hydraulic actuators, and fuel systems.

The core advantage of a PTFE energized seal in aerospace is not just the resilience of the PTFE material itself, but the synergy between the stable PTFE jacket and the live spring energizer. This combination provides a constant, reliable sealing force under conditions where traditional elastomer seals would fail due to thermal effects or compression set.

The Unique Demands of Aerospace Environments

To appreciate why these seals are so critical, we must first understand the hostile conditions they operate in. Aerospace applications are defined by rapid and extreme environmental changes that place immense stress on components.

Extreme Temperature Swings

Aerospace systems must function flawlessly from ground temperatures to the frigid conditions at high altitudes and the intense heat generated by engines. Seals may be exposed to cryogenic fuels and then, moments later, extreme operational heat.

Extreme Pressure Differentials

Seals must perform reliably in both the vacuum of space and within high-pressure hydraulic or fuel systems. This requires a solution that can seal effectively against both internal and external pressure without failure.

Aggressive Chemical Exposure

Components are routinely exposed to a variety of harsh fluids, including jet fuel, hydraulic oils, de-icing agents, and cleaning solvents. A seal material must resist chemical attack to prevent degradation, swelling, or embrittlement.

How PTFE Energized Seals Meet These Demands

The design of a spring-energized PTFE seal directly addresses each of these challenges by combining the strengths of two distinct components: the seal jacket and the energizer.

The Role of the PTFE Jacket

The outer jacket, made from Polytetrafluoroethylene (PTFE), serves as the primary interface.

Its material properties provide three key benefits:

- Chemical Inertness: PTFE is one of the most corrosion-resistant materials known, capable of withstanding virtually all aerospace fluids without degrading.

- Low Friction: The exceptionally low coefficient of friction minimizes drag and wear in dynamic applications like actuators and rotating shafts, improving efficiency and service life.

- Dimensional Stability: PTFE has very low water absorption and excellent stability, ensuring it maintains its shape and fit over time.

The Function of the Spring Energizer

Inside the PTFE jacket sits a metallic spring. This is the critical component for ensuring reliability across wide temperature ranges.

While the PTFE jacket provides the sealing surface, the spring provides a constant, live mechanical force. This force pushes the seal lips against the gland walls, maintaining a tight seal even when temperature changes cause the hardware or the seal itself to expand or contract.

This is a direct solution to compression set and aging embrittlement, common failure modes for traditional elastomer seals in extreme cold or heat.

The Synergy of the System

The PTFE jacket offers the robust, low-friction, and chemically resistant surface. The spring energizer provides the persistent force needed to maintain a positive seal across the vast temperature and pressure spectrums that define aerospace operations.

Understanding the Trade-offs

While highly effective, PTFE energized seals are not a universal solution without considerations. Understanding their limitations is key to successful implementation.

Material Selection and Fillers

Pure, or "virgin," PTFE can be relatively soft and susceptible to "cold flow" or creep under load. To counter this, various fillers (such as carbon, glass, or graphite) are blended with the PTFE.

These fillers enhance properties like wear resistance and stiffness. However, selecting a filled PTFE compound is a trade-off, as it can sometimes slightly reduce the material's universal chemical resistance or increase friction.

Design and Installation Sensitivity

Compared to a simple O-ring, a spring-energized seal is a more complex component. The hardware gland must be designed with precise dimensions and surface finishes to ensure proper seal performance.

Furthermore, installation requires care to avoid damaging the relatively rigid PTFE sealing lips, which could compromise the seal's integrity from the start.

Making the Right Choice for Your Application

Selecting the right seal requires aligning its strengths with your specific engineering goal. The combination of the jacket material and spring energizer can be tailored to meet precise demands.

- If your primary focus is dynamic sealing (actuators, rotating shafts): The key is the low friction and high wear resistance of the filled PTFE jacket, which ensures long life and low energy loss.

- If your primary focus is static sealing in extreme temperatures (fuel lines, cryogenics): The spring energizer's ability to compensate for thermal expansion and contraction is the most critical factor for maintaining seal integrity.

- If your primary focus is chemical compatibility (aggressive hydraulic fluids, fuel systems): The inherent inertness of the PTFE material itself is the primary benefit, preventing seal degradation over its service life.

By understanding the interplay between the PTFE jacket and the spring energizer, you can confidently specify a sealing solution that ensures reliability in the most demanding aerospace conditions.

Summary Table:

| Key Quality | Benefit in Aerospace |

|---|---|

| Extreme Temperature Resilience | Maintains seal integrity from cryogenic to high-heat conditions |

| Chemical Inertness | Resists degradation from jet fuel, hydraulic oils, and solvents |

| Spring Energizer | Provides constant sealing force, preventing compression set |

| Low Friction & Wear Resistance | Ideal for dynamic applications like actuators and rotating shafts |

| Dimensional Stability | Ensures long-term performance with low water absorption |

Need a reliable sealing solution for your aerospace application? KINTEK specializes in manufacturing high-performance PTFE components, including custom energized seals designed to withstand extreme temperatures, pressures, and aggressive chemicals. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal that meets the rigorous demands of the aerospace industry. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations for successful PTFE machining? Master Precision for Soft Materials

- What makes PTFE suitable for custom industrial parts? Discover the Ideal Material for Harsh Environments

- Why is PTFE an ideal material for butterfly valves? Superior Sealing and Chemical Resistance

- What makes PTFE bushes durable in extreme conditions? Unmatched Thermal & Chemical Stability

- What is counter rotation in rotary seals and why is it problematic? Prevent Catastrophic Seal Failure

- What is Expanded PTFE joint sealant used for? Seal Imperfect Flanges in Extreme Conditions

- Why are ePTFE gaskets more expensive? Unlocking Superior Sealing Performance

- What are the main technical features of PTFE rotary shaft seals? Unlock Extreme Performance & Reliability