In high-performance applications, Polytetrafluoroethylene (PTFE) is a primary material for specialty cable insulation and jacketing. It is most commonly found in high-frequency coaxial cables where signal integrity is paramount, and in insulated wires designed to operate in extreme environments, such as those with very high or low temperatures and exposure to aggressive chemicals.

PTFE is not a default choice for cable insulation but a strategic one. It is specified when operational demands—extreme temperatures, chemical exposure, or critical signal integrity—exceed the capabilities of more common and less expensive materials like PVC or polyethylene.

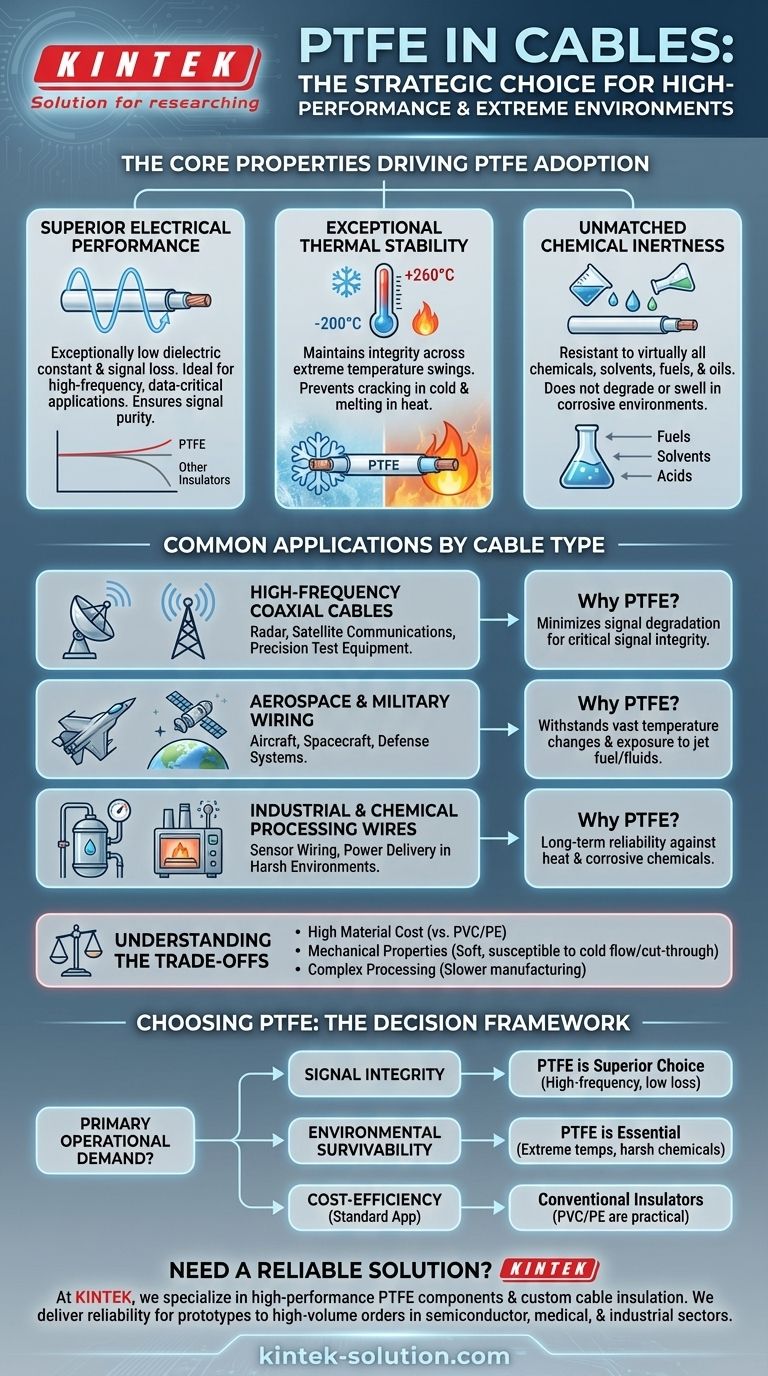

The Core Properties Driving PTFE Adoption in Cabling

To understand why PTFE is chosen for these niche applications, you must understand its unique combination of electrical, thermal, and chemical properties. It is a material engineered for performance, not for cost-savings.

Superior Electrical Performance

PTFE has an exceptionally low dielectric constant and low signal loss, even at very high frequencies. This means it is an almost perfectly transparent medium for electrical signals.

For high-frequency signals, like those in radar or satellite communications, other insulators can absorb and distort the signal. PTFE minimizes this degradation, ensuring the signal that enters the cable is nearly identical to the one that exits.

Exceptional Thermal Stability

PTFE maintains its integrity across an incredibly wide temperature range. It is reliably used in applications from cryogenic temperatures (-200°C) found in aerospace to high-temperature environments (up to 260°C) near engines or industrial heaters.

This stability prevents the insulation from becoming brittle and cracking in the cold or melting and deforming in the heat, which would lead to cable failure and short circuits.

Unmatched Chemical Inertness

PTFE is resistant to virtually all common chemicals, solvents, fuels, and oils. It does not swell, dissolve, or degrade when exposed to corrosive substances.

This makes it the only viable choice for wiring in chemical processing plants, medical equipment that undergoes harsh sterilization, and automotive or aerospace applications where contact with hydraulic fluids or fuel is possible.

Common Applications by Cable Type

These properties make PTFE the material of choice in several distinct categories of high-performance cables.

High-Frequency Coaxial Cables

These cables are the backbone of modern communication and testing. PTFE's low signal loss is critical for systems like radar, satellite uplinks, and high-precision electronic test equipment where signal purity is non-negotiable.

Aerospace and Military Wiring

In aircraft and spacecraft, every component must be lightweight, reliable, and resistant to extreme conditions. PTFE insulation provides excellent electrical performance while withstanding the vast temperature swings and exposure to jet fuel and hydraulic fluids common in these environments.

Industrial and Chemical Processing Wires

For sensor wiring and power delivery inside chemical reactors, industrial ovens, or downhole oil drilling equipment, no other insulator offers the same level of resistance to heat and corrosive chemicals. PTFE ensures long-term reliability in environments that would destroy a standard cable in minutes.

Understanding the Trade-offs

While its performance is unparalleled, PTFE is not the solution for every problem. An objective assessment requires acknowledging its limitations.

High Material Cost

PTFE is significantly more expensive than commodity plastics like Polyvinyl Chloride (PVC) or Polyethylene (PE). Its use is only justified when the performance requirements demand it and the cost of failure is high.

Mechanical Properties

PTFE is a relatively soft material. It has a high susceptibility to "cold flow," or creep, where the material deforms over time under sustained pressure. It is also more susceptible to cut-through damage than harder plastics unless jacketed or reinforced.

Processing Challenges

Manufacturing cables with PTFE is a more complex and slower process than working with typical thermoplastics. This specialized handling contributes further to the final product's higher cost.

Choosing PTFE Cable for Your Application

Your decision should be driven entirely by the operational demands of your project.

- If your primary focus is signal integrity: PTFE is the superior choice for high-frequency or high-data-rate applications where minimizing signal loss and distortion is critical.

- If your primary focus is environmental survivability: PTFE is essential for cables that must function reliably despite extreme temperatures or direct contact with harsh chemicals.

- If your primary focus is cost-efficiency for a standard application: Conventional insulators like PVC or PE are more practical and appropriate for general-purpose wiring in controlled environments.

Ultimately, selecting PTFE is an engineering decision to prioritize performance and reliability in environments where failure is not an option.

Summary Table:

| Cable Type | Key Application | Why PTFE is Used |

|---|---|---|

| High-Frequency Coaxial | Radar, Satellite Communications | Superior signal integrity, low dielectric loss |

| Aerospace & Military | Aircraft, Spacecraft Wiring | Extreme temperature stability, chemical resistance |

| Industrial & Chemical | Sensors in harsh environments | Unmatched chemical inertness, heat resistance |

Need a reliable cable solution for a demanding environment?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom cable insulation and jacketing. Our expertise in precision fabrication ensures your cables can withstand extreme temperatures, harsh chemicals, and maintain critical signal integrity.

Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver the reliability your application demands.

Contact us today to discuss your specific requirements and let our experts provide a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components