In short, Teflon (PTFE) packing is not the optimal choice in applications involving extreme temperatures above 260°C (500°F), when sealing certain aggressive chemicals like molten alkali metals, in high-pressure situations where material creep is a concern, or when handling abrasive media. In these scenarios, the material's inherent limitations can lead to seal failure, equipment damage, or safety hazards.

While Teflon packing is a versatile workhorse for general-purpose sealing, its effectiveness is defined by its physical and chemical boundaries. Understanding these limits is the key to preventing premature failure and selecting a truly reliable sealing solution.

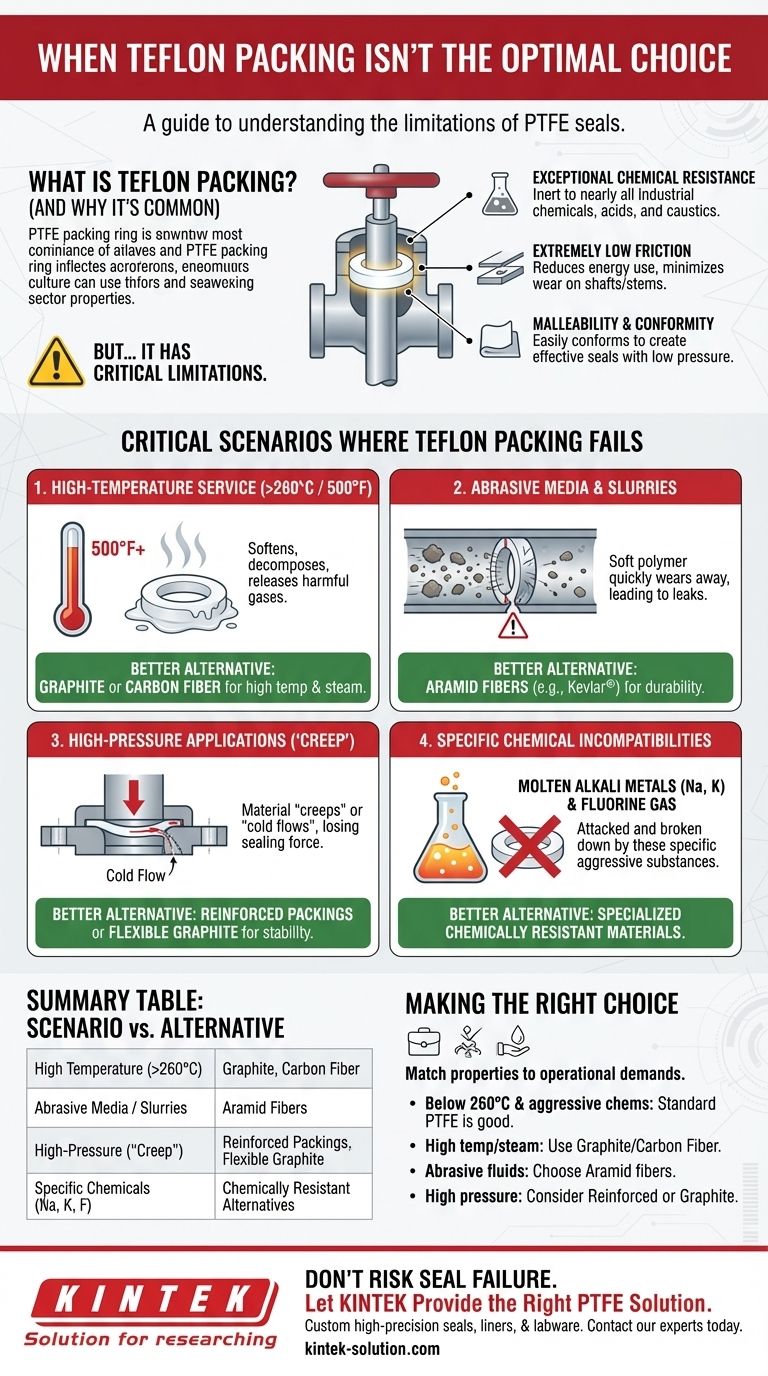

Why Teflon is a Common Go-To Sealant

Before examining its limitations, it is important to understand why PTFE packing is so widely used. Its popularity stems from a powerful combination of three key properties.

Exceptional Chemical Resistance

With very few exceptions, Teflon is inert to nearly all industrial chemicals, acids, and caustics. This makes it a safe and reliable choice for a vast range of fluid-handling applications.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This reduces the energy needed to operate a valve or pump and minimizes wear on shafts and stems.

Malleability and Conformity

PTFE is a soft, pliable material. This allows the packing to easily conform to the shape of the stuffing box and shaft, creating an effective seal with relatively low gland pressure.

Critical Scenarios Where Teflon Packing Fails

Despite its strengths, selecting Teflon packing in the wrong environment can be a critical mistake. Its properties become liabilities under certain operational stresses.

1. High-Temperature Service

This is the most well-known limitation. Above 260°C (500°F), PTFE begins to soften significantly and decompose. This process not only causes a loss of the seal but also releases potentially harmful gases.

For high-temperature applications, such as steam valves or exhaust systems, materials like graphite or carbon fiber are required as they can withstand much higher temperatures without degradation.

2. Abrasive Media and Slurries

Teflon is a relatively soft polymer. When the fluid being sealed contains hard particles, grit, or suspended solids (a slurry), it acts like sandpaper against the packing.

This abrasive action will quickly wear away the soft PTFE, leading to leakage in a very short time. Harder, more durable materials like aramid fibers (e.g., Kevlar®) are specifically designed for these punishing services.

3. High-Pressure Applications with "Creep"

A significant, often overlooked, weakness of PTFE is its tendency to "creep" or "cold flow." Under sustained pressure, the material will slowly deform and flow away from the point of highest stress.

In a high-pressure valve or flange, this means the packing can lose its sealing force over time, even at room temperature, resulting in a gradual leak that requires constant re-tightening. For high-pressure static seals, graphite-based or reinforced packings offer far greater dimensional stability.

4. Specific Chemical Incompatibilities

While chemically resistant to most substances, Teflon is attacked by a few. The most common exceptions are molten alkali metals (like liquid sodium or potassium) and, in some cases, hot, high-pressure elemental fluorine gas. These substances can react with and break down the polymer structure.

Understanding the Trade-offs

The choice of sealing material is always a matter of balancing competing properties. Teflon's strengths are directly linked to its weaknesses.

Malleability vs. Extrusion Resistance

The softness that allows Teflon to seal easily also makes it susceptible to being pushed or "extruded" out of gaps under high pressure. This is why anti-extrusion rings are often used with PTFE seals in higher-pressure systems.

Low Friction vs. Low Strength

Teflon's slick, non-stick surface is a result of weak molecular bonds. This same property contributes to its relatively low tensile strength and poor resistance to abrasion and creep compared to engineered fiber packings.

Environmental Persistence

The same chemical stability that makes Teflon so durable also means it does not biodegrade. For applications where environmental impact is a primary design driver, alternative materials may need to be considered.

Making the Right Choice for Your Application

Selecting the correct packing material prevents unplanned downtime, improves safety, and optimizes performance. Use the specific demands of the service to guide your decision.

- If your primary focus is sealing aggressive chemicals below 260°C (500°F): Standard Teflon (PTFE) packing is an excellent and cost-effective choice.

- If your application involves high temperatures, especially steam: Graphite or carbon-fiber-based packing is the industry standard for reliability.

- If you are pumping abrasive fluids, crystals, or slurries: Choose a packing made from tough aramid fibers or a durable composite blend.

- If you have a high-pressure static seal that must maintain torque: Consider flexible graphite or a reinforced packing that resists creep and cold flow.

Ultimately, matching the material's properties to the operational demands of your equipment is the foundation of a reliable sealing strategy.

Summary Table:

| Scenario | Why Teflon Fails | Better Alternative |

|---|---|---|

| High Temperature (>260°C / 500°F) | Softens, decomposes, releases harmful gases | Graphite, Carbon Fiber |

| Abrasive Media / Slurries | Soft polymer wears away quickly | Aramid Fibers (e.g., Kevlar®) |

| High-Pressure Applications | Material "creeps" or "cold flows," losing seal | Reinforced Packings, Flexible Graphite |

| Specific Chemicals | Attacked by molten alkali metals, fluorine gas | Chemically Resistant Alternatives |

Don't Risk Seal Failure. Let KINTEK Provide the Right PTFE Solution.

While Teflon has its limits, the right PTFE component—designed for your specific pressure, temperature, and chemical environment—is critical for reliability. KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact performance demands. Contact our experts today to discuss your application and get a sealing solution that won't let you down.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the minimum and maximum sizes for machining PTFE parts? Design for Success with No Universal Limits

- What are the different grades of PTFE used in rotary shaft seals? Choose the Right Filler for Peak Performance

- What are some alternatives to Teflon for machining? Optimize Your Material Selection for Specialized Applications

- What factors should be considered when determining if PTFE bellows are the best material? Select the Right Material for Your System

- What are the key benefits of PTFE energized seals for the aerospace industry? Unmatched Reliability in Extreme Environments

- How is structured PTFE manufactured? The Process Behind High-Performance PTFE Components

- What are PTFE gaskets and what are their key properties? Solve Sealing Challenges in Extreme Conditions

- What are the advantages of using Teflon lip seals? Achieve Unmatched Reliability in Extreme Conditions