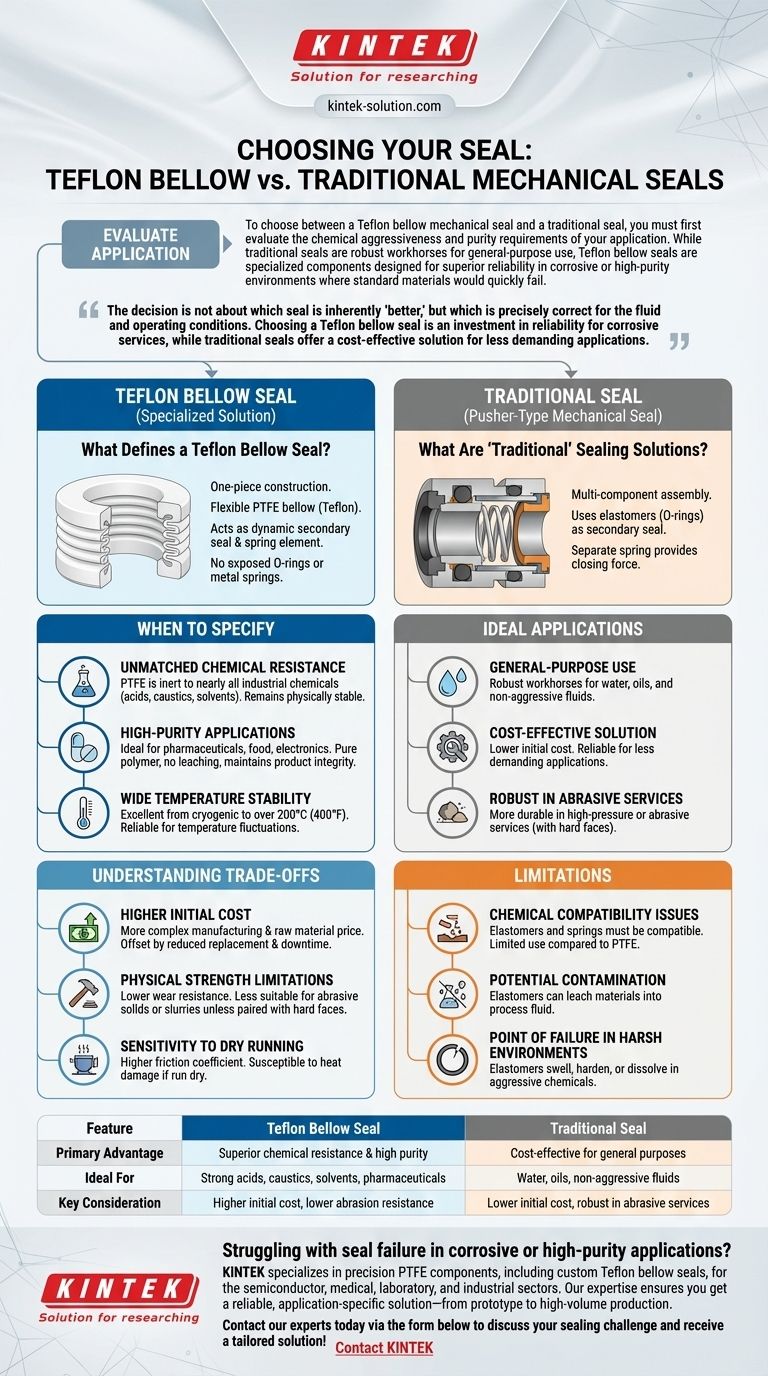

To choose between a Teflon bellow mechanical seal and a traditional seal, you must first evaluate the chemical aggressiveness and purity requirements of your application. While traditional seals are robust workhorses for general-purpose use, Teflon bellow seals are specialized components designed for superior reliability in corrosive or high-purity environments where standard materials would quickly fail.

The decision is not about which seal is inherently "better," but which is precisely correct for the fluid and operating conditions. Choosing a Teflon bellow seal is an investment in reliability for corrosive services, while traditional seals offer a cost-effective solution for less demanding applications.

The Core Difference: Material and Design

Understanding the fundamental construction of each seal type is the first step in making an informed decision. Their differences in material and design dictate their ideal applications.

What Defines a Teflon Bellow Seal?

A Teflon bellow seal is distinguished by its unique, one-piece construction. The flexible, convoluted bellow is made from Polytetrafluoroethylene (PTFE), commonly known as Teflon.

This bellow acts as both a dynamic secondary seal and the spring element, eliminating the need for separate O-rings and metal springs that would be exposed to the process fluid. This design makes its performance almost entirely dependent on the near-universal chemical resistance of PTFE.

What Are "Traditional" Sealing Solutions?

"Traditional" typically refers to pusher-type mechanical seals. These are multi-component assemblies that use elastomers, such as O-rings, as the secondary seal.

A separate spring (or multiple springs) provides the closing force on the seal faces. The wetted parts—the O-ring and spring—must be chemically compatible with the process fluid, which limits their use compared to the inert nature of a solid Teflon bellow.

When to Specify a Teflon Bellow Seal

A Teflon bellow seal is not a universal upgrade; it is a specific solution for challenging environments where traditional seals are a point of failure.

Unmatched Chemical Resistance

The primary reason to select a Teflon bellow seal is for unmatched chemical resistance. PTFE is inert to nearly all industrial chemicals, including strong acids, caustics, solvents, and oxidizers.

Where elastomers in a traditional seal would swell, harden, or dissolve, a Teflon bellow remains physically stable, ensuring seal integrity and preventing catastrophic leaks.

High-Purity Applications

In industries like pharmaceuticals, food production, and electronics, preventing product contamination is critical. Teflon bellows are ideal for these services.

Unlike elastomers that can leach materials into the process fluid, PTFE is a pure polymer that maintains product integrity.

Wide Temperature Stability

PTFE offers excellent thermal stability across a broad range of temperatures, from cryogenic conditions to over 200°C (400°F). This makes Teflon bellow seals a reliable choice for applications with significant temperature fluctuations.

Understanding the Trade-offs

No sealing solution is without its limitations. Objectively weighing the trade-offs is crucial for aligning your choice with operational realities.

The Initial Cost Factor

Teflon bellow seals typically have a higher initial cost than their traditional counterparts. This is due to the more complex manufacturing process and the price of the raw PTFE material.

However, this cost must be weighed against the potential for frequent replacement, downtime, and product loss if a less-resistant traditional seal fails prematurely in a corrosive service.

Physical Strength Limitations

While chemically robust, PTFE is a relatively soft material. It has lower wear resistance and physical strength compared to the metals and hard-face materials used in traditional seals.

This makes standard Teflon bellow seals less suitable for services with significant abrasive solids or slurries unless paired with appropriate hard seal faces.

Sensitivity to Dry Running

Teflon has a higher coefficient of friction than many standard seal face materials. This can make Teflon bellows more susceptible to heat damage if the pump is allowed to run dry (without liquid to lubricate and cool the seal faces).

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical demand of the system you are sealing.

- If your primary focus is handling aggressive chemicals or ensuring high purity: The superior chemical inertness of a Teflon bellow seal is non-negotiable.

- If your primary focus is cost-effectiveness for general-purpose fluids like water or oils: A traditional mechanical seal with the appropriate elastomer is the most economical and reliable choice.

- If your primary focus is durability in high-pressure or abrasive services: A robust, traditional multi-spring seal with hard faces is often the more durable solution.

Ultimately, a proper seal selection is a technical decision that balances material science against the operational demands of your system to ensure long-term reliability.

Summary Table:

| Feature | Teflon Bellow Seal | Traditional Seal |

|---|---|---|

| Primary Advantage | Superior chemical resistance & high purity | Cost-effective for general purposes |

| Ideal For | Strong acids, caustics, solvents, pharmaceuticals | Water, oils, non-aggressive fluids |

| Key Consideration | Higher initial cost, lower abrasion resistance | Lower initial cost, robust in abrasive services |

Struggling with seal failure in corrosive or high-purity applications? KINTEK specializes in precision PTFE components, including custom Teflon bellow seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a reliable, application-specific solution—from prototype to high-volume production. Contact our experts today via the form below to discuss your sealing challenge and receive a tailored solution! Contact KINTEK

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining