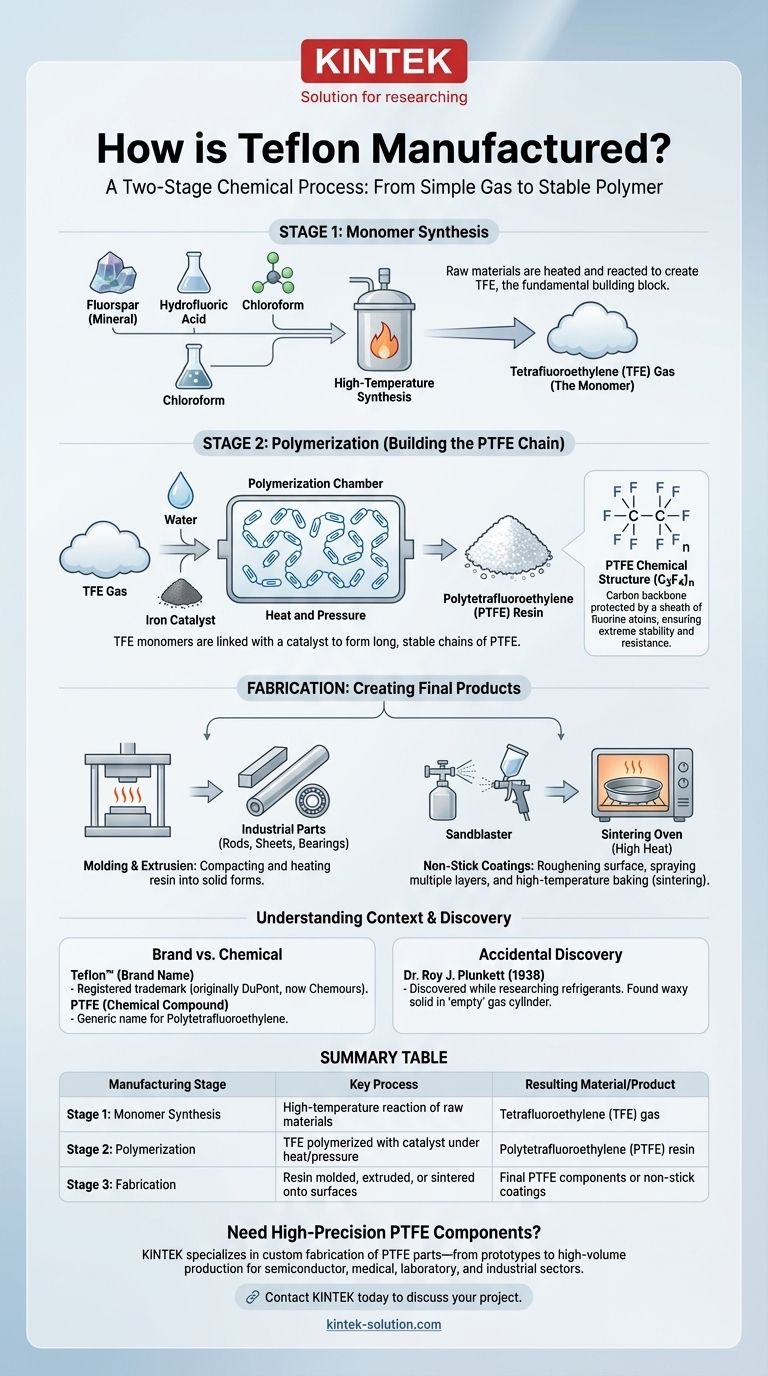

At its core, Teflon is created through a two-stage chemical process. First, common industrial chemicals are used to synthesize a gas called tetrafluoroethylene (TFE). This gas is then subjected to heat and pressure with a catalyst in a process called polymerization, which links the individual gas molecules into long, stable chains to form the solid resin known as polytetrafluoroethylene (PTFE), the chemical substance behind the Teflon brand.

The manufacturing of Teflon is a process of forging exceptionally strong chemical bonds. It transforms a simple gas into a highly stable solid polymer, and it is the strength of these carbon-fluorine bonds that gives the final material its signature non-stick, heat-resistant, and chemically inert properties.

From Raw Materials to a Unique Monomer

The entire process begins by creating the essential building block for the final polymer. This first stage is about synthesizing the monomer gas from which everything else is built.

The Starting Ingredients

The journey starts with common industrial materials. The key ingredients are fluorspar (a mineral), hydrofluoric acid, and chloroform.

Creating Tetrafluoroethylene (TFE)

These ingredients are heated together in a chemical reaction chamber. This high-temperature synthesis breaks them down and reassembles them to create tetrafluoroethylene (TFE), a simple gas that serves as the foundational molecule, or monomer.

The Polymerization Process: Building the PTFE Chain

Once the TFE monomer has been created and purified, the next stage is to link these individual molecules together into the long, powerful chains that form the final material.

Linking the Monomers

The TFE gas is cooled, liquefied, and then mixed with water and an iron catalyst. This initiates the polymerization reaction. Think of it as linking thousands of identical paper clips (the TFE molecules) into a single, incredibly long, and strong chain.

The Resulting Chemical Structure

This process creates polytetrafluoroethylene (PTFE), a polymer with the chemical formula (C2F4)n. The "n" signifies a vast number of repeating C2F4 units. In this structure, a strong carbon backbone is completely surrounded by a protective sheath of fluorine atoms, making it extraordinarily stable and resistant.

Fabricating Final Teflon Products

The raw PTFE resin—typically a white, granular solid—is rarely used in its initial form. It must be processed and shaped into the final products we recognize.

Creating Solid Shapes

For industrial parts like rods, sheets, or bearings, the PTFE resin is shaped using methods like molding or extrusion. This involves compacting the resin and heating it under pressure to fuse the particles into a solid, durable form.

Applying Non-Stick Coatings

For cookware, the process is more nuanced. The metal pan surface is first roughened by sandblasting to create a texture for the coating to grip. Multiple thin layers of PTFE resin are then sprayed on and baked at high temperatures. This baking process, called sintering, permanently bonds the layers to each other and to the pan.

Understanding the Context: Brand vs. Chemical

A common point of confusion is the relationship between the brand name "Teflon" and the actual chemical compound. Understanding the distinction is key to understanding the material.

Teflon: The Brand Name

Teflon™ is the registered trademark for PTFE, originally discovered by DuPont and now owned by its spin-off company, Chemours. It is the most widely recognized brand name for this type of coating.

PTFE: The Chemical Compound

Polytetrafluoroethylene (PTFE) is the generic chemical name for the substance itself. Other companies can and do manufacture PTFE under different brand names for various applications.

The Accidental Discovery

This remarkable material was discovered by accident in 1938. Dr. Roy J. Plunkett was researching new refrigerants when he found a gas cylinder that appeared empty but was still heavy. Upon cutting it open, he discovered a waxy, incredibly slippery solid inside—the world's first PTFE.

How This Process Defines Teflon's Use

The specific manufacturing steps are directly responsible for the properties that make PTFE so valuable in different fields. By understanding the goal, you can appreciate which part of the process is most critical.

- If your primary focus is industrial applications: The polymerization process, which creates a chemically inert and durable material, is key for parts like seals, gaskets, and bearings that must withstand harsh environments.

- If your primary focus is non-stick cookware: The final application method of layering and high-temperature baking is what creates the tough, heat-resistant surface you rely on for cooking.

- If your primary focus is scientific understanding: The strength of the carbon-fluorine bond, forged during synthesis, is the fundamental reason for PTFE's extreme resistance to heat, chemicals, and adhesion.

Understanding how Teflon is made reveals that its extraordinary properties are not an accident, but the direct result of a precise chemical architecture built one molecule at a time.

Summary Table:

| Manufacturing Stage | Key Process | Resulting Material/Product |

|---|---|---|

| Stage 1: Monomer Synthesis | High-temperature reaction of fluorspar, hydrofluoric acid, and chloroform. | Tetrafluoroethylene (TFE) gas. |

| Stage 2: Polymerization | TFE is polymerized with a catalyst under heat and pressure. | Polytetrafluoroethylene (PTFE) resin. |

| Stage 3: Fabrication | Resin is molded, extruded, or sintered onto surfaces like cookware. | Final PTFE components (seals, liners, labware) or non-stick coatings. |

Need High-Precision PTFE Components?

KINTEK specializes in the custom fabrication of PTFE parts—from prototypes to high-volume production. Our expertise in manufacturing seals, liners, labware, and other components ensures they meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. We leverage the superior properties of PTFE to deliver parts with exceptional chemical resistance, thermal stability, and low friction.

Contact KINTEK today to discuss your project requirements and discover how our precision PTFE solutions can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its primary applications? A Guide to Teflon's Industrial Uses

- What makes Teflon plastic sheets highly resistant to chemicals? The Power of a Molecular Fortress

- How does Teflon perform in outdoor applications? Unmatched Durability Against Weather and UV

- What type of polymerization is used to create Teflon? A Guide to Free-Radical Chain-Growth

- What is the chemical composition of PTFE? Unlocking the Power of Carbon-Fluorine Bonds

- How does PTFE perform in chemical-heavy environments? Unmatched Chemical Resistance for Demanding Applications

- Why is Teflon considered important in modern technology? For Unmatched Chemical and Thermal Resistance

- What is the volume resistivity and power factor of PTFE? Discover the Ultimate Electrical Insulator