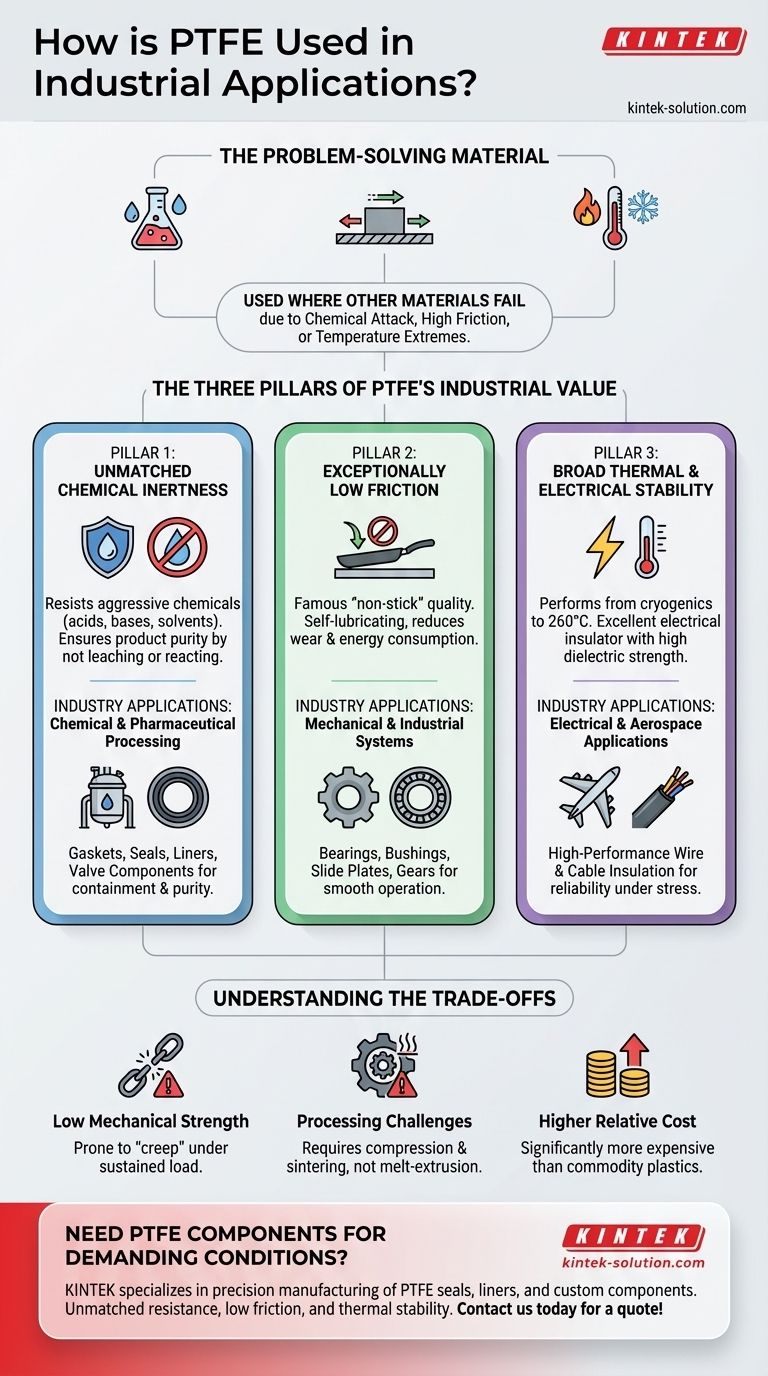

At its core, Polytetrafluoroethylene (PTFE) is used in industrial applications where other materials fail due to chemical attack, high friction, or temperature extremes. It is most commonly fabricated into components like seals, gaskets, bearings, and non-stick coatings, serving critical functions in industries ranging from chemical processing and aerospace to pharmaceuticals and food manufacturing.

PTFE's value is not derived from a single feature, but from its unique combination of three key properties: near-total chemical inertness, an extremely low coefficient of friction, and a wide operating temperature range. This makes it a premier problem-solving material for the most demanding engineering environments.

The Three Pillars of PTFE's Industrial Value

To understand why PTFE is so ubiquitous, you must understand the foundational properties that drive its selection. It's rarely chosen for its structural strength, but for its ability to survive and perform where other plastics and even metals cannot.

Pillar 1: Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists degradation from a vast range of aggressive chemicals, including strong acids, bases, solvents, and oxidizing agents.

This chemical stability makes it the default material for containing and transporting highly corrosive substances. It ensures product purity by not leaching or reacting, which is a non-negotiable requirement in the pharmaceutical and food industries.

Pillar 2: Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous "non-stick" quality. This property is inherent to the material and does not degrade over time.

In mechanical applications, this translates to self-lubricating parts. Using PTFE for bearings, slide plates, and gears significantly reduces wear, lowers energy consumption, and minimizes maintenance requirements compared to materials like nylon or acetal.

Pillar 3: Broad Thermal & Electrical Stability

PTFE maintains its properties across a very wide temperature range, performing reliably in both cryogenic conditions and high-heat environments up to 260°C (500°F).

Furthermore, it is an excellent electrical insulator with high dielectric strength. This combination of thermal stability and electrical resistance makes it ideal for high-performance wire and cable insulation, especially in aerospace and electronics where reliability is paramount.

How PTFE Is Deployed Across Key Industries

The theoretical properties of PTFE translate directly into tangible solutions for specific industrial challenges.

In Chemical and Pharmaceutical Processing

The primary driver here is containment and purity. PTFE is used to fabricate gaskets, seals, and linings for reactors, valves, and transport systems.

This prevents hazardous leaks of corrosive chemicals and protects the integrity of sensitive products like Active Pharmaceutical Ingredients (APIs) from contamination. PTFE expansion joints are also common, accommodating thermal expansion in pipe systems while resisting chemical attack.

In Mechanical and Industrial Systems

The goal is to reduce friction and wear. PTFE is molded into plain bearings, bushings, and slide plates for machinery.

These components operate smoothly without external lubrication, extending the life of the machinery and reducing the energy needed to run it. It is also applied as a surface coating to reduce friction on other parts.

In Electrical and Aerospace Applications

The key needs are insulation and reliability under stress. PTFE is used as a high-performance insulator for wires and cables.

Its ability to withstand extreme temperatures and resist chemical exposure makes it a critical material for wiring in aircraft engines and other demanding aerospace and electronic systems where failure is not an option.

Understanding the Trade-offs of PTFE

No material is perfect. While PTFE excels in extreme conditions, its limitations are important to recognize for proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for structural components that bear significant loads, as it can be prone to "creep" or cold flow, where the material deforms permanently under sustained pressure.

Processing and Fabrication Challenges

Unlike common thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques. It must be compressed and sintered—a process closer to metallurgy or ceramics—which can be more complex and costly.

Higher Relative Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than commodity plastics like polyethylene or polypropylene. Its use is justified only when its unique combination of properties is necessary to solve a specific engineering challenge that cheaper materials cannot address.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary problem you need to solve.

- If your primary focus is corrosion and contamination control: Use PTFE for vessel linings, pipe systems, seals, and gaskets where chemical inertness and purity are critical.

- If your primary focus is reducing friction and wear: Use PTFE for self-lubricating bearings, slide plates, and low-friction surface coatings in mechanical systems.

- If your primary focus is high-temperature or electrical insulation: Use PTFE for high-reliability wire insulation and specialized seals in aerospace, electronics, or power generation.

PTFE is ultimately an engineering tool for solving problems of survivability in extreme chemical, thermal, and mechanical environments.

Summary Table:

| PTFE Property | Key Industrial Application |

|---|---|

| Chemical Inertness | Seals, gaskets, liners for chemical & pharmaceutical processing |

| Low Friction | Self-lubricating bearings, bushings, slide plates |

| Thermal/Electrical Stability | High-performance wire insulation for aerospace & electronics |

Need PTFE components that can withstand your most demanding conditions?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver unmatched chemical resistance, low friction, and thermal stability—whether you need prototypes or high-volume production.

Contact us today to discuss your specific application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application