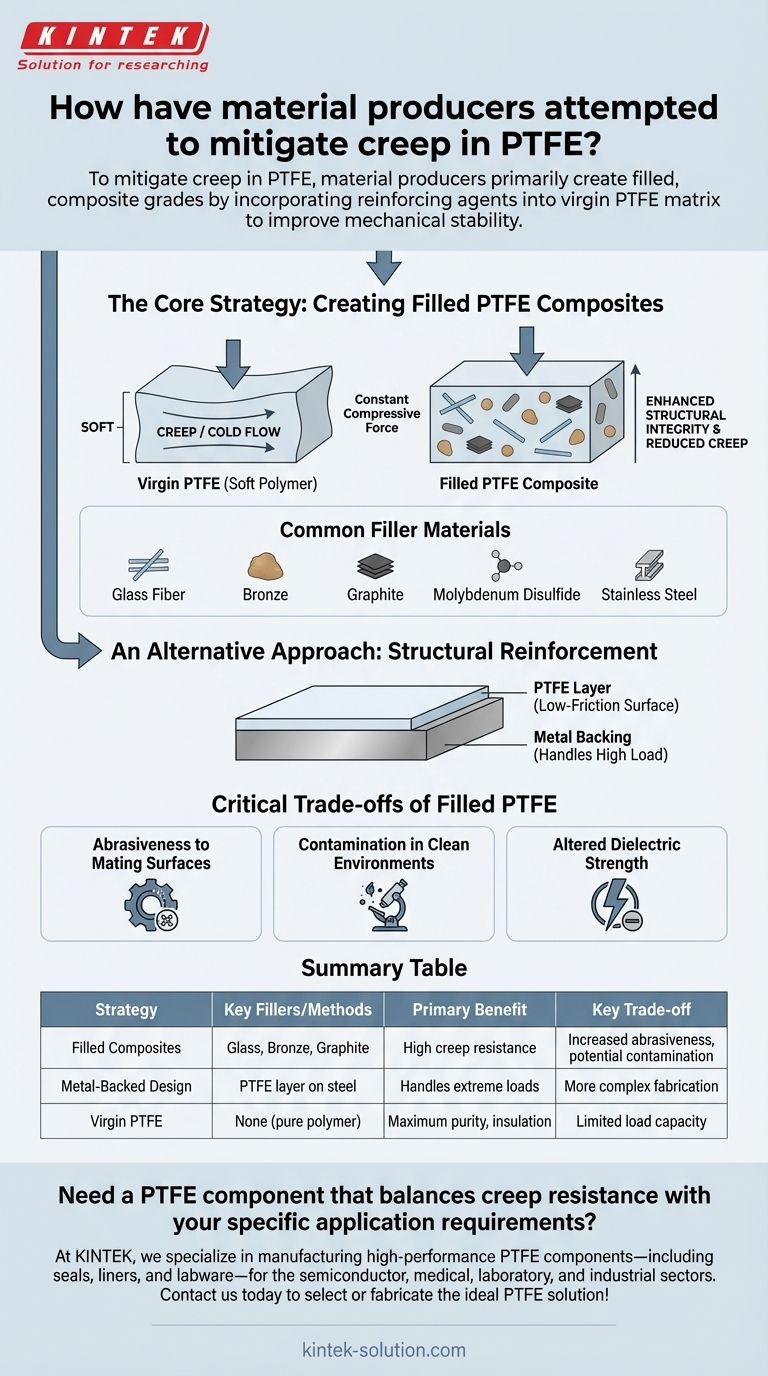

To mitigate creep in PTFE, material producers have primarily focused on creating filled, composite grades of the material. These engineered versions incorporate various reinforcing agents into the virgin PTFE matrix to improve its mechanical stability under sustained load.

The fundamental challenge is that PTFE's natural tendency to deform under constant pressure limits its use in high-load applications. The solution involves reinforcing the material with fillers, but this introduces critical trade-offs regarding abrasion, purity, and electrical properties that must be carefully considered.

The Core Strategy: Creating Filled PTFE Composites

The most common and effective method for improving PTFE's mechanical properties is to transform it from a single polymer into a composite material by adding fillers.

Why Virgin PTFE Creeps

Polytetrafluoroethylene (PTFE) is a soft polymer that can deform over time when subjected to a constant compressive force, a phenomenon known as creep or cold flow. This limits its use as a structural component in applications involving sustained high pressure.

How Fillers Improve Creep Resistance

By introducing a secondary material, or filler, into the PTFE matrix, producers create a composite with enhanced structural integrity. These filler particles are harder and more dimensionally stable than the surrounding polymer, effectively reinforcing it and significantly reducing its tendency to creep.

Common Filler Materials

Producers use a variety of fillers to achieve different performance characteristics. Common choices include:

- Glass Fiber

- Bronze

- Graphite

- Molybdenum Disulfide

- Stainless Steel

An Alternative Approach: Structural Reinforcement

For applications with exceptionally high loads where even filled grades are insufficient, a different strategy is employed.

Metal-Backed Components

Instead of modifying the material itself, the component's design is altered. A thin layer of PTFE (often a filled grade) is bonded to a rigid metal backing, such as a steel washer. The metal substrate handles the high mechanical load, preventing deformation, while the PTFE provides the low-friction surface.

Critical Trade-offs of Filled PTFE

While fillers successfully reduce creep, they fundamentally change the nature of the material and introduce new considerations. This is not a "free upgrade"; it is a design compromise.

Abrasiveness to Mating Surfaces

Adding hard particles like glass or bronze can make the PTFE component abrasive. This can cause premature wear on softer mating surfaces, such as shafts or housings, which is a critical factor in dynamic sealing or bearing applications.

Contamination in Clean Environments

Filled grades can shed microscopic particles of the filler material over time. This makes them unsuitable for applications where purity is paramount, such as in food processing, medical devices, or semiconductor manufacturing.

Altered Dielectric Strength

Virgin PTFE is an excellent electrical insulator. However, adding conductive fillers like graphite, bronze, or stainless steel dramatically reduces its dielectric strength and changes its electrical properties, making it unsuitable for many insulating applications.

Selecting the Right Solution for Your Application

Choosing the correct PTFE variant requires balancing the need for creep resistance against the specific demands of your operating environment.

- If your primary focus is high-load mechanical performance: A filled grade is the standard solution, with bronze or stainless steel fillers offering excellent compressive strength.

- If your primary focus is reducing friction on a soft shaft: Consider a graphite or molybdenum disulfide filled PTFE, which adds lubricity with less abrasiveness than glass.

- If your primary focus is a clean environment: Virgin PTFE may be the only option, requiring you to manage the load to stay within its creep limits.

- If your primary focus is electrical insulation: You must use virgin PTFE, as most common performance-enhancing fillers are conductive.

Ultimately, understanding these reinforcement strategies and their inherent compromises is the key to successfully deploying PTFE in demanding applications.

Summary Table:

| Strategy | Key Fillers/Methods | Primary Benefit | Key Trade-off |

|---|---|---|---|

| Filled Composites | Glass, Bronze, Graphite | High creep resistance | Increased abrasiveness, potential contamination |

| Metal-Backed Design | PTFE layer on steel | Handles extreme loads | More complex fabrication |

| Virgin PTFE | None (pure polymer) | Maximum purity, insulation | Limited load capacity |

Need a PTFE component that balances creep resistance with your specific application requirements?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard filled grade for high-load scenarios or a custom virgin PTFE solution for clean environments, we provide precision production from prototypes to high-volume orders.

Contact us today to discuss your project and let our experts help you select or fabricate the ideal PTFE solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is Glass-Filled PTFE and what are its properties? A Guide to Enhanced PTFE Performance

- How does PTFE contribute to semiconductor manufacturing? Ensure Purity and Prevent Contamination

- What are the key properties of PTFE that make it ideal for industrial use? Unlock Unmatched Performance in Harsh Environments

- What are the primary properties of Teflon that make it a 'powerhouse plastic'? Unlock Unmatched Performance

- What are the applications of PTFE laminated fabric in special apparel? A Guide to Advanced Protection & Comfort

- How is Teflon applied in the medical sector? Unlocking Biocompatibility and Sterility for Healthcare

- Why is Teflon so slippery? The Secret is a Self-Lubricating, Sacrificial System

- What are the benefits of carbon-filled PTFE? Enhance Strength, Wear & Conductivity