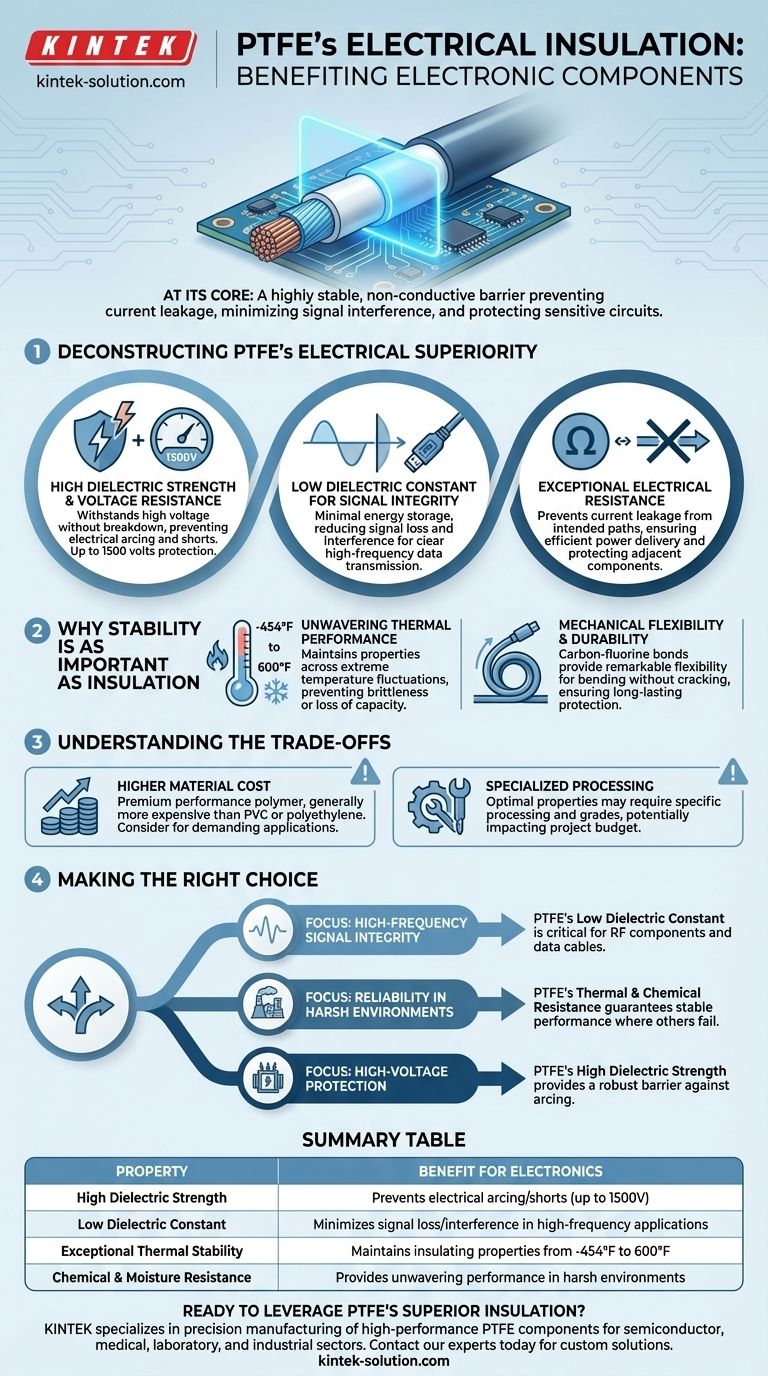

At its core, PTFE's electrical insulation benefits electronic components by creating a highly stable and non-conductive barrier. This barrier prevents current leakage, minimizes signal interference, and protects sensitive circuits from high-voltage damage, ensuring both reliability and high performance.

The true value of PTFE in electronics isn't just its ability to block electricity. It's the unique combination of high voltage resistance, minimal signal interference (low dielectric constant), and unwavering stability across extreme temperatures and chemical exposures that makes it a uniquely reliable insulator.

Deconstructing PTFE's Electrical Superiority

To understand why PTFE is a preferred insulator, we need to look beyond the general label and examine the specific properties that make it so effective in demanding electronic applications.

High Dielectric Strength and Voltage Resistance

Dielectric strength measures a material's ability to withstand high voltage without breaking down and allowing current to pass through.

PTFE excels in this area, capable of resisting high voltages, with some specifications rating it for up to 1500 volts. This prevents electrical arcing or short-circuiting, protecting components from catastrophic failure.

Low Dielectric Constant for Signal Integrity

The dielectric constant is a critical factor in high-frequency applications, such as data cables, connectors, and antennas. It indicates how much electrical energy a material stores when exposed to an electric field.

PTFE has a very low dielectric constant. This means it absorbs minimal energy from the signal passing through the conductor it insulates. The result is lower signal loss and reduced interference, preserving the integrity and clarity of high-speed data transmission.

Exceptional Electrical Resistance

Beyond withstanding high voltage, PTFE exhibits extremely high electrical resistance. This property is fundamental to its role as an insulator.

This high resistance ensures that electrical current does not "leak" away from its intended path. This protects adjacent sensitive components from stray currents and ensures the efficient delivery of power throughout a circuit.

Why Stability is as Important as Insulation

An insulator's properties are only valuable if they remain consistent under real-world operating conditions. PTFE's exceptional stability across a range of environmental stressors is what sets it apart.

Unwavering Thermal Performance

Electronic components generate heat and often operate in environments with fluctuating temperatures.

PTFE maintains its excellent electrical properties across an exceptionally wide temperature range, from as low as -454°F to as high as 600°F. Unlike other materials that can become brittle or lose insulating capacity, PTFE remains stable and reliable.

Resilience Against Chemicals and Moisture

PTFE is famously impervious to nearly all solvents and chemicals. It also does not absorb moisture.

This chemical inertness is vital in industrial or harsh environments where exposure could degrade other insulating materials, leading to electrical failure.

Mechanical Flexibility and Durability

The underlying carbon-fluorine bonds in PTFE's structure provide remarkable flexibility.

This allows it to be used effectively as insulation for wires and cables that need to bend and move without cracking or compromising the protective barrier. This ensures long-lasting physical and electrical protection.

Understanding the Trade-offs

While PTFE offers an elite combination of properties, it is essential to consider its practical limitations for any design.

Higher Material Cost

PTFE is a premium performance polymer. As a result, it is generally more expensive than more common insulating materials like PVC or polyethylene.

For applications where the operating environment is mild and performance demands are low, a less expensive alternative may be sufficient.

Specialized Processing

While versatile, achieving optimal properties for the most demanding applications may require specialized grades of PTFE.

These specialized materials can require specific processing techniques and may come at an even higher cost, which must be factored into the overall project budget.

Making the Right Choice for Your Application

Selecting the right insulator depends entirely on the primary goal of your electronic design.

- If your primary focus is high-frequency signal integrity: PTFE's low dielectric constant is its most critical feature, ensuring minimal signal loss in RF components and high-speed data cables.

- If your primary focus is reliability in harsh environments: PTFE's unmatched thermal and chemical resistance guarantees stable insulation performance where other materials would fail.

- If your primary focus is high-voltage protection: PTFE's high dielectric strength provides a robust barrier against electrical arcing, making it ideal for transformers, connectors, and power components.

Ultimately, choosing PTFE is an investment in the long-term stability and performance of your electronic system.

Summary Table:

| Property | Benefit for Electronics |

|---|---|

| High Dielectric Strength | Prevents electrical arcing and short-circuits, even at high voltages (up to 1500V). |

| Low Dielectric Constant | Minimizes signal loss and interference in high-frequency applications (e.g., data cables, RF components). |

| Exceptional Thermal Stability | Maintains insulating properties from -454°F to 600°F, ensuring reliability in extreme conditions. |

| Chemical & Moisture Resistance | Provides unwavering performance in harsh environments where other materials would degrade. |

Ready to leverage PTFE's superior insulation for your electronic components?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, labware, and custom fabricated parts. Whether you're developing prototypes or scaling up for high-volume production in the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your components meet the highest standards of reliability and performance.

Contact our experts today to discuss how our custom PTFE solutions can protect and enhance your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications