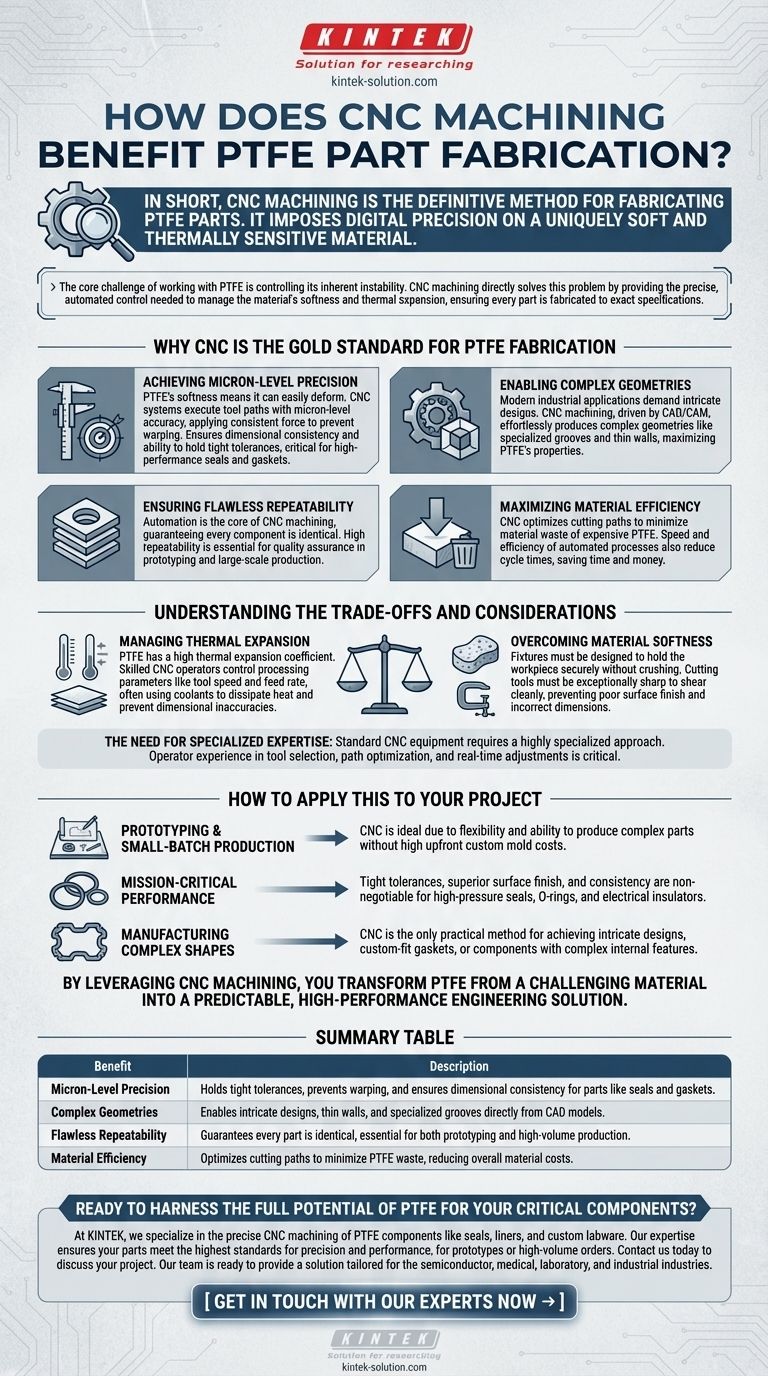

In short, CNC machining is the definitive method for fabricating Polytetrafluoroethylene (PTFE) parts because it imposes digital precision on a uniquely soft and thermally sensitive material. This combination unlocks the ability to create complex components with tight tolerances and exceptional repeatability, something manual methods cannot consistently achieve.

The core challenge of working with PTFE is controlling its inherent instability. CNC machining directly solves this problem by providing the precise, automated control needed to manage the material's softness and thermal expansion, ensuring every part is fabricated to exact specifications.

Why CNC is the Gold Standard for PTFE Fabrication

While PTFE is valued for its low friction and chemical resistance, its physical properties make it difficult to shape accurately. CNC (Computer Numerical Control) machining systematically overcomes these material-specific hurdles.

Achieving Micron-Level Precision

PTFE's softness means it can easily deform or compress under pressure. CNC systems execute tool paths with micron-level accuracy, applying consistent force and speed that prevent warping.

This ensures dimensional consistency and the ability to hold tight tolerances, which is critical for high-performance parts like seals and gaskets where even minor deviations can lead to failure.

Enabling Complex Geometries

Modern industrial applications demand parts with intricate designs, such as specialized grooves, thin walls, or complex internal features.

CNC machining, driven by CAD/CAM software, can produce these complex geometries effortlessly. This capability allows engineers to design parts that take full advantage of PTFE’s properties without being limited by manufacturing constraints.

Ensuring Flawless Repeatability

Manual fabrication is subject to human error, leading to variations between parts. Automation is the core of CNC machining, guaranteeing that every component is identical to the last.

This high repeatability is essential for quality assurance in both small-batch prototyping and large-scale production, ensuring uniform performance across all parts.

Maximizing Material Efficiency

PTFE can be an expensive material. CNC machining optimizes the cutting path to minimize material waste, a significant advantage over less precise methods.

Furthermore, the speed and efficiency of automated processes reduce cycle times, saving both time and money in the overall manufacturing process.

Understanding the Trade-offs and Considerations

Successfully machining PTFE is not as simple as loading the material and pressing a button. It requires a deep understanding of the material's behavior and how to compensate for it.

Managing Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes caused by tool friction.

A skilled CNC operator must carefully control processing parameters, such as tool speed and feed rate, and often use coolants to dissipate heat and prevent dimensional inaccuracies.

Overcoming Material Softness

The inherent softness of PTFE demands specialized handling. Fixtures must be designed to hold the workpiece securely without crushing or deforming it.

Cutting tools must be exceptionally sharp to shear the material cleanly rather than pushing or tearing it, which would result in a poor surface finish and incorrect dimensions.

The Need for Specialized Expertise

While standard CNC equipment can be used, the approach is highly specialized. The operator's experience is a critical factor.

Choosing the right tool material, optimizing the tool path to reduce cutting forces, and making real-time adjustments are skills that separate a successful outcome from a failed part.

How to Apply This to Your Project

CNC machining allows you to fully harness PTFE's benefits for critical components. The decision to use it depends on your project's specific requirements.

- If your primary focus is prototyping or small-batch production: CNC is ideal due to its flexibility and ability to produce complex parts without the high upfront cost of custom molds.

- If your primary focus is mission-critical performance: The tight tolerances, superior surface finish, and consistency of CNC are non-negotiable for parts like high-pressure seals, O-rings, and electrical insulators.

- If your primary focus is manufacturing complex shapes: CNC is the only practical method for achieving intricate designs, custom-fit gaskets, or components with complex internal features.

By leveraging CNC machining, you transform PTFE from a challenging material into a predictable, high-performance engineering solution.

Summary Table:

| Benefit | Description |

|---|---|

| Micron-Level Precision | Holds tight tolerances, prevents warping, and ensures dimensional consistency for parts like seals and gaskets. |

| Complex Geometries | Enables intricate designs, thin walls, and specialized grooves directly from CAD models. |

| Flawless Repeatability | Guarantees every part is identical, essential for both prototyping and high-volume production. |

| Material Efficiency | Optimizes cutting paths to minimize PTFE waste, reducing overall material costs. |

Ready to harness the full potential of PTFE for your critical components?

At KINTEK, we specialize in the precise CNC machining of PTFE components like seals, liners, and custom labware. Our expertise in managing material softness and thermal expansion ensures your parts meet the highest standards for precision and performance, whether you need prototypes or high-volume orders.

Contact us today to discuss your project requirements and get a quote. Our team is ready to provide a solution tailored for the semiconductor, medical, laboratory, and industrial industries.

Get in touch with our experts now →

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability