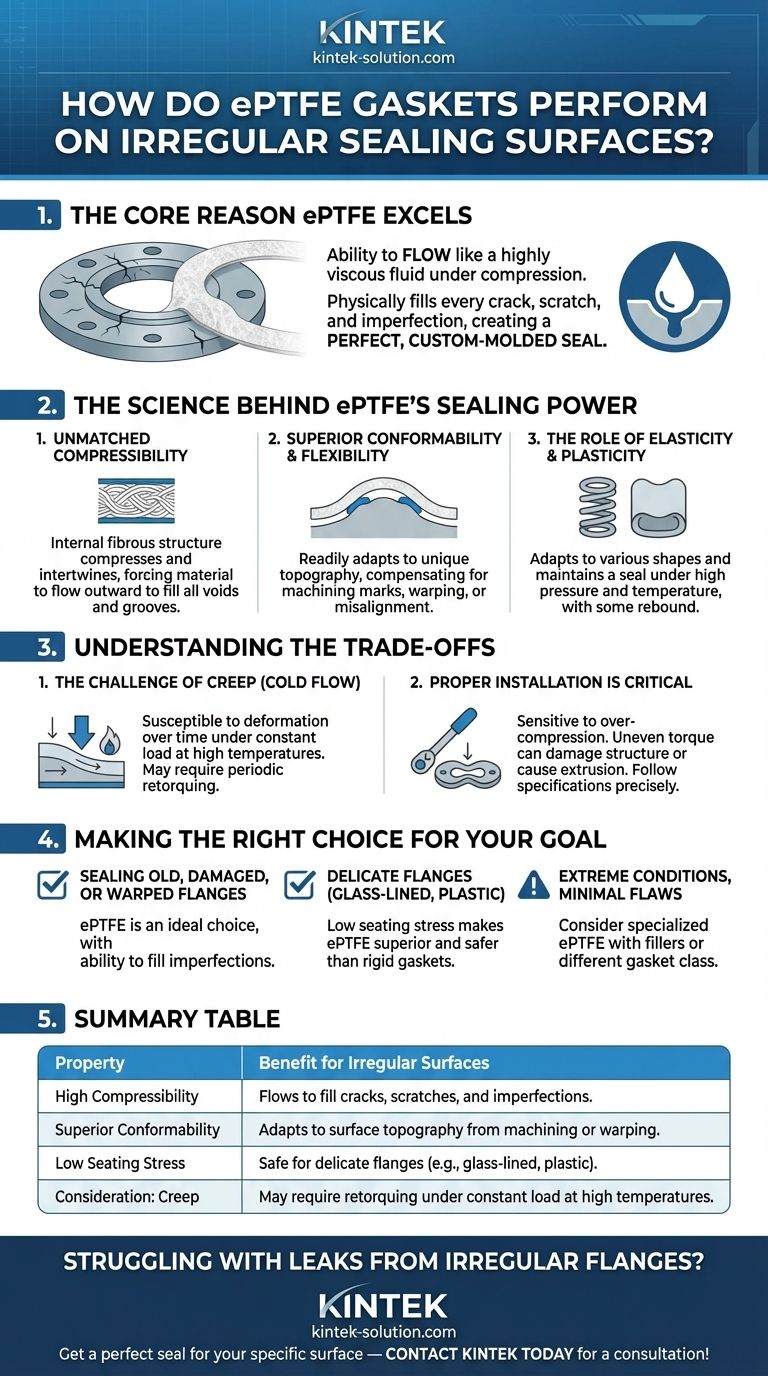

To put it simply, ePTFE gaskets perform exceptionally well on irregular sealing surfaces. Their unique material properties allow them to create a tight, reliable seal where more rigid materials would fail. This performance is a direct result of their extreme softness and high compressibility.

The core reason ePTFE excels is its ability to flow like a highly viscous fluid under compression. It physically fills every crack, scratch, and imperfection on a flange face, creating a perfect, custom-molded seal for that specific surface.

The Science Behind ePTFE's Sealing Power

To understand why ePTFE is so effective, you need to look at its fundamental material characteristics. It isn't just a soft material; its internal structure is engineered for conformability.

Unmatched Compressibility

ePTFE is defined by its high compressibility. When you tighten the bolts on a flange, the gasket doesn't just get thinner; its internal fibrous structure compresses and intertwines.

This action forces the material to flow outward and into any available space, effectively filling voids, grooves, and surface irregularities.

Superior Conformability and Flexibility

This material exhibits excellent flexibility and conformability. It readily adapts to the unique topography of the mating surfaces.

This allows the gasket to compensate for deviations caused by machining marks, stiffness deformation, or slight installation misalignments, ensuring a secure seal even in challenging, real-world conditions.

The Role of Elasticity and Plasticity

ePTFE possesses good elasticity and plasticity, which allows it to adapt to various shapes while maintaining a seal under high temperature and pressure.

Some of its rebound characteristics mean that as internal system pressure increases, the force pushing the gasket against the sealing surfaces also increases, reinforcing the seal's integrity.

Understanding the Trade-offs

While ePTFE is an exceptional problem-solver for irregular surfaces, no material is perfect. Acknowledging its limitations is key to using it correctly.

The Challenge of Creep (Cold Flow)

The very softness that makes ePTFE so conformable also makes it susceptible to creep, or "cold flow."

Under a constant compressive load, especially at elevated temperatures, the material can slowly deform over time. This can lead to a loss of bolt torque and a reduction in sealing stress, which may require periodic retorquing.

Proper Installation is Critical

Because the material is so soft, it's more sensitive to over-compression than harder gaskets.

Applying excessive or uneven torque can damage the gasket's internal structure or cause it to extrude out of the flange, compromising the seal. Always follow the manufacturer's torque specifications precisely.

Making the Right Choice for Your Goal

Selecting the right gasket means matching the material's strengths to your specific problem.

- If your primary focus is sealing old, damaged, or warped flanges: ePTFE is an ideal choice, as its ability to fill imperfections is second to none.

- If your application involves delicate flanges (like glass-lined or plastic): The low seating stress required for ePTFE makes it a superior and safer option than rigid gaskets.

- If your system has extreme temperatures and pressures with minimal surface flaws: You may need to consider a specialized ePTFE with fillers (like silica or glass) to improve creep resistance, or a different gasket class entirely.

By understanding how ePTFE's properties address surface irregularities, you can confidently specify it to solve your most difficult sealing challenges.

Summary Table:

| Property | Benefit for Irregular Surfaces |

|---|---|

| High Compressibility | Flows to fill cracks, scratches, and imperfections. |

| Superior Conformability | Adapts to surface topography from machining or warping. |

| Low Seating Stress | Safe for delicate flanges (e.g., glass-lined, plastic). |

| Consideration: Creep | May require retorquing under constant load at high temperatures. |

Struggling with leaks from irregular or damaged flanges? KINTEK manufactures high-performance ePTFE gaskets and seals specifically designed to solve these exact challenges. Our components provide the superior conformability and low seating stress you need for a reliable seal on warped, scratched, or delicate surfaces in semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders to meet your precise specifications.

Get a perfect seal for your specific surface — Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE O-rings? Superior Sealing for Extreme Conditions

- What makes ePTFE sheets a preferred material in the food, beverage, and pharmaceutical sectors? Ensuring Product Purity and Safety

- Why are PTFE-lined butterfly valves resistant to corrosion? The Power of an Inert Barrier

- In what types of mechanical assemblies are Teflon bushes particularly valuable? Enhance Durability in Rotating and Sliding Parts

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments

- How does the cost of PTFE PCBs compare to FR4 PCBs? A Guide to High-Frequency Material Selection

- What are some variations of control valve designs? A Guide to Linear vs. Rotary Motion Valves

- What are the key benefits of PTFE coatings in corrosion resistance? Achieve Unmatched Protection for Your Components