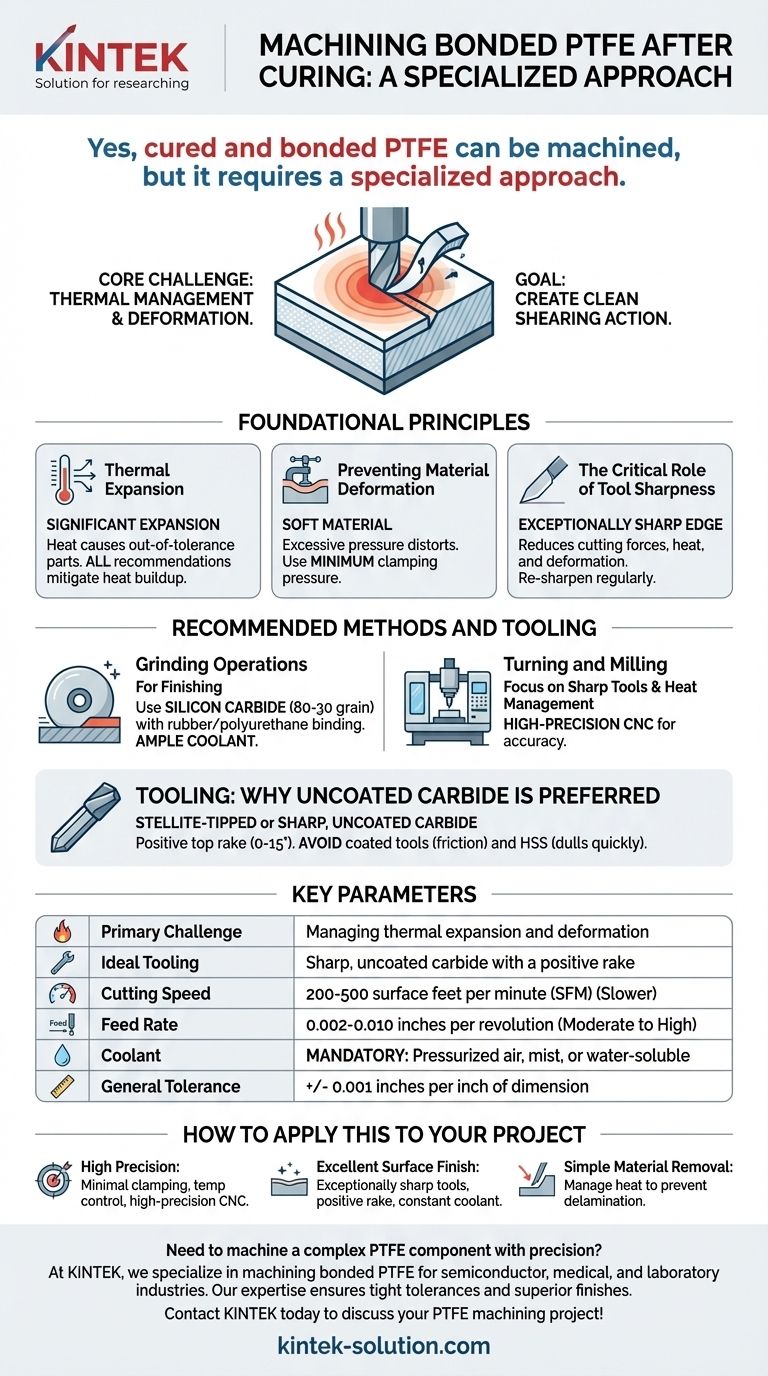

Yes, cured and bonded PTFE can be machined, but it requires a specialized approach. Success depends on using conventional methods like grinding, turning, or milling while adapting tools and parameters to manage the material's unique properties, such as high thermal expansion and softness.

The core challenge in machining PTFE is not material hardness, but thermal management and deformation. The goal is to use exceptionally sharp tools to create a clean shearing action, generating a distinct chip rather than rubbing or melting the material, which leads to poor finishes and dimensional inaccuracy.

Foundational Principles for Machining PTFE

To machine PTFE effectively, you must control for its inherent characteristics. Ignoring these principles is the primary cause of failed attempts.

The Primary Challenge: Thermal Expansion

PTFE expands and contracts significantly with temperature changes. The friction from machining can generate enough heat to cause the part to go out of tolerance before the cut is even finished.

All subsequent recommendations—from tool selection to coolant use—are designed to mitigate this heat buildup.

Preventing Material Deformation

PTFE is a soft material. Excessive clamping pressure in a vise or chuck will easily distort the part, leading to inaccurate final dimensions.

Likewise, dull tools or aggressive cuts will push and deform the material rather than cutting it cleanly.

The Critical Role of Tool Sharpness

An exceptionally sharp cutting edge is non-negotiable. A sharp tool reduces cutting forces, which in turn minimizes frictional heat and material deformation.

Tools should be re-sharpened regularly to maintain this keen edge, as even minor wear can degrade performance dramatically.

Recommended Machining Methods and Tooling

While standard machines are used, the tooling and setup are specific to PTFE's demands.

Tooling: Why Uncoated Carbide is Preferred

Stellite-tipped or sharp, uncoated carbide tools are the ideal choice. Coated tools can increase friction, while high-speed steel (HSS) dulls too quickly.

A positive top rake (between 0 and 15 degrees) on the tool helps create a shearing action and reduces cutting forces, promoting a cleaner cut.

Grinding Operations

Grinding is a common and effective method for finishing cured PTFE.

Use silicon carbide grindstones (grain size 80-30) with a rubber or polyurethane binding. For finer finishing, an aluminum oxide stone can be used. The grinding speed should be similar to that used for cast iron, with an open stone and ample coolant.

Turning and Milling

For turning and milling, the focus remains on sharp tools and heat management. High-precision CNC machines provide the control needed for accurate and repeatable results.

Understanding the Pitfalls and Key Parameters

Success lies in balancing several competing factors. Getting one wrong can compromise the entire operation.

The Speed vs. Feed Rate Balance

There is a delicate relationship between cutting speed and feed rate.

Generally, use slower cutting speeds (200-500 surface feet per minute is a starting range) and moderate to high feed rates (0.002 to 0.010 inches per revolution). This combination ensures the tool is actively removing a chip rather than rubbing against the surface, which would generate excessive heat. A feed rate that is too slow causes rubbing; one that is too fast can cause chipping.

The Importance of Coolant

Sufficient cooling is mandatory. Use pressurized air, a mist system, or a water-soluble coolant to continuously flush heat and chips away from the cutting zone. This is the most direct way to combat thermal expansion during the cut.

Workholding and Clamping Pressure

Apply the minimum clamping pressure necessary to hold the workpiece securely. This prevents the material from distorting or compressing, which would ruin dimensional accuracy.

Achieving Tight Tolerances

A good rule of thumb for general tolerances on PTFE parts is +/- 0.001 inches per inch of dimension. Tighter tolerances are achievable but require highly stable, reinforced PTFE grades and meticulous control over the entire machining process.

Post-Machining: Deburring

After machining, PTFE will have sharp edges or "burrs." These must be removed carefully with a sharp knife or dedicated deburring tool, as they can affect the performance or assembly of the final part.

How to Apply This to Your Project

Your specific parameters will depend on your primary objective.

- If your primary focus is high precision and tight tolerances: Prioritize minimal clamping pressure, a temperature-controlled environment, and high-precision CNC control.

- If your primary focus is an excellent surface finish: Emphasize using exceptionally sharp, uncoated carbide tools with a positive rake and a constant supply of coolant.

- If your primary focus is simple material removal: You can be more flexible, but managing heat to prevent delamination of the bond remains the critical factor.

Ultimately, machining PTFE successfully is a process of finesse that rewards a focus on sharp tools and thermal control.

Summary Table:

| Key Parameter | Recommendation |

|---|---|

| Primary Challenge | Managing thermal expansion and deformation |

| Ideal Tooling | Sharp, uncoated carbide with a positive rake |

| Cutting Speed | 200-500 surface feet per minute (SFM) |

| Feed Rate | 0.002-0.010 inches per revolution |

| Coolant | Pressurized air, mist, or water-soluble coolant is mandatory |

| General Tolerance | +/- 0.001 inches per inch of dimension |

Need to machine a complex PTFE component with precision?

At KINTEK, we specialize in machining bonded PTFE for the semiconductor, medical, and laboratory industries. Our expertise in managing thermal expansion and using specialized tooling ensures your parts meet tight tolerances and superior surface finishes.

We offer custom fabrication from prototypes to high-volume orders. Let us handle the challenges of machining PTFE so you get a reliable, high-performance part.

Contact KINTEK today to discuss your PTFE machining project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What operating conditions are PTFE-lined plug valves particularly suitable for? Control Corrosive & High-Purity Fluids

- What makes PTFE extruded rods suitable for bearings and bushings? Discover Low-Friction, Maintenance-Free Performance

- What are the key properties of PTFE rotary shaft seals? Solve Extreme Chemical, Temperature, and Speed Challenges

- Why is deburring critical after machining PTFE? Ensure Component Integrity and Reliability

- How does the non-stick surface of PTFE flange gaskets benefit installation and maintenance? Cut Costs & Downtime

- What types of PTFE-lined bearings are available? Find the Right Bearing for Your Load and Motion Needs

- What are the advantages of graphite packing over PTFE packing? Superior Performance in High-Temp & High-Speed Applications

- What tools are used in the CNC machining of PTFE? Achieve Clean, Precise Cuts