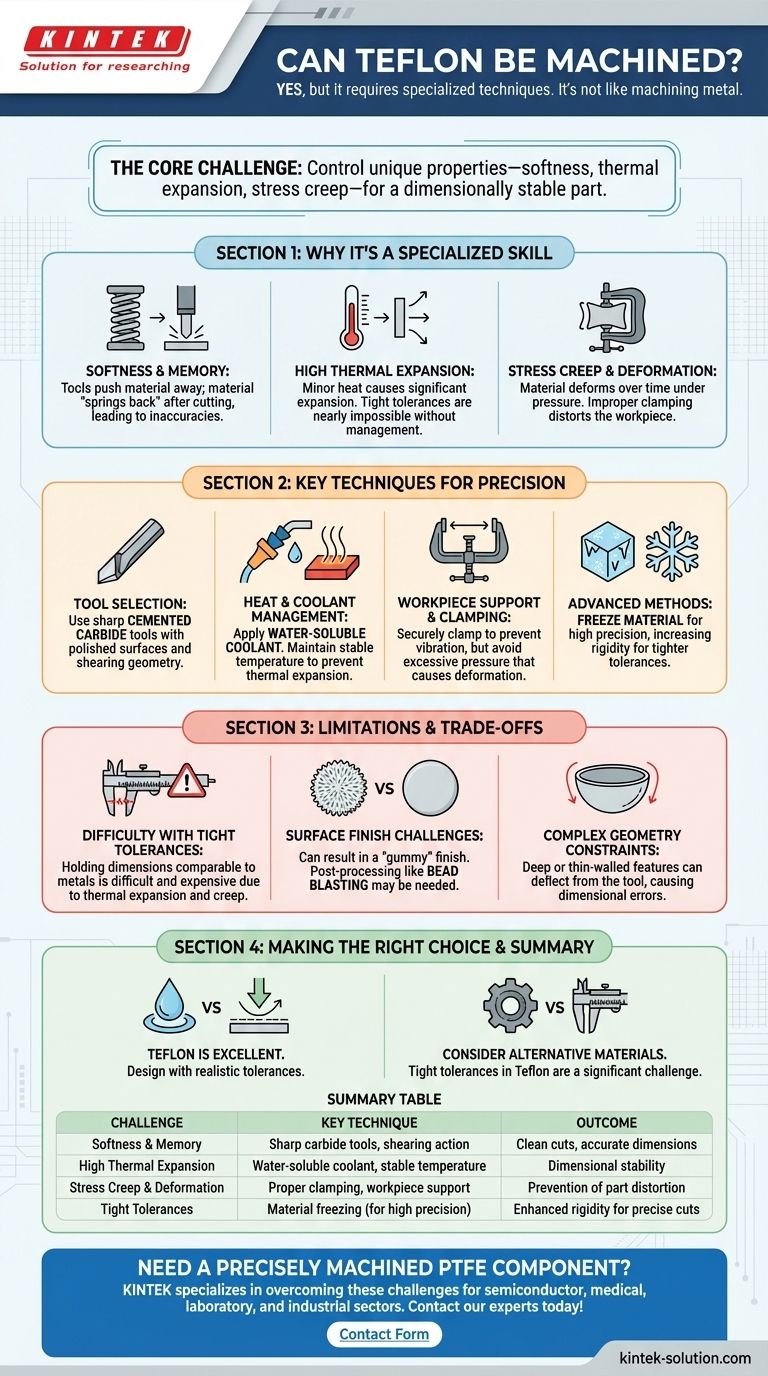

Yes, Teflon can be machined, but its unique properties demand specialized techniques that differ significantly from those used for metals or even other plastics. While it can be shaped using conventional methods, its inherent softness, high thermal expansion, and tendency to deform under pressure require careful management to achieve accurate results.

The core challenge of machining Teflon isn't whether it can be cut, but how to control its unique physical properties—softness, thermal expansion, and stress creep—to produce a dimensionally stable and precise final part.

Why Machining Teflon is a Specialized Skill

Teflon (PTFE) is not like other materials. Its desirable traits in application—low friction, chemical inertness, and flexibility—become direct challenges during the machining process.

Softness and Material Memory

Teflon is exceptionally soft, which means tools can easily push the material away rather than cutting it cleanly. This can lead to dimensional inaccuracies and a poor surface finish. The material also has a "memory" and can spring back slightly after a cut.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even minor heat generated during machining can cause the material to expand significantly, making it nearly impossible to hold tight tolerances if not properly managed.

Stress Creep and Deformation

The material is prone to stress creep, meaning it will deform over time when under pressure. Improper clamping or excessive tool pressure during machining can easily distort the workpiece, leading to a part that is out of specification.

Key Techniques for Precision Teflon Machining

Success hinges on accommodating the material's properties, not fighting against them. This involves specific choices in tooling, temperature control, and workpiece handling.

Tool Selection and Geometry

Use extremely sharp cemented carbide tools with polished surfaces. The geometry should be designed to create a shearing action rather than a pushing one, which helps ensure a clean cut and minimizes heat generation.

Heat and Coolant Management

Applying a water-soluble coolant is essential to dissipate heat and prevent thermal expansion from ruining the part's dimensions. Maintaining a stable temperature throughout the process is critical.

Workpiece Support and Clamping

The workpiece must be securely clamped to prevent vibration, but not so tightly that it causes deformation. Proper support along the length of the material is crucial to avoid bending or distortion from tool pressure.

Advanced Methods for High Precision

For applications demanding very tight tolerances, machinists may temporarily freeze the material before cutting. This makes the Teflon much more rigid, significantly reducing deformation and allowing for more precise cuts.

Understanding the Limitations and Trade-offs

While highly versatile, Teflon presents clear limitations that make it unsuitable for certain designs or when ultimate precision is the only goal.

Difficulty with Tight Tolerances

Achieving extremely tight tolerances is the single greatest challenge. Due to the combined effects of thermal expansion and stress creep, holding dimensions comparable to what is possible with metals is difficult and expensive.

Surface Finish Challenges

Without the right tools and techniques, Teflon can have a "gummy" or "fuzzy" surface finish. Post-processing techniques like bead blasting can be used to achieve a smoother, more uniform surface.

Complex Geometry Constraints

While most shapes are possible, deep or thin-walled features like bowls or unsupported disks can be particularly challenging. The material's flexibility can cause walls to deflect away from the cutting tool, leading to inconsistent thickness and dimensional errors.

Making the Right Choice for Your Application

Selecting Teflon should be a deliberate decision based on its unique end-use benefits, while fully understanding the manufacturing complexities involved.

- If your primary focus is chemical resistance or low friction: Teflon is an excellent choice, provided you can design the part with realistic dimensional tolerances in mind.

- If your primary focus is high-precision, rigid components: You should consider alternative materials, as the inherent nature of Teflon makes achieving tight tolerances a significant and costly challenge.

Ultimately, successful Teflon fabrication is a partnership between design and manufacturing, requiring a deep understanding of the material's unique behavior.

Summary Table:

| Challenge | Key Technique | Outcome |

|---|---|---|

| Softness & Material Memory | Sharp carbide tools, shearing action | Clean cuts, accurate dimensions |

| High Thermal Expansion | Water-soluble coolant, stable temperature | Dimensional stability |

| Stress Creep & Deformation | Proper clamping, workpiece support | Prevention of part distortion |

| Tight Tolerances | Material freezing (for high precision) | Enhanced rigidity for precise cuts |

Need a precisely machined PTFE component?

At KINTEK, we specialize in overcoming the unique challenges of Teflon machining. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your PTFE seals, liners, and labware meet your exact specifications for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to deliver dimensionally stable parts with superior surface finishes, leveraging advanced techniques to manage thermal expansion and stress creep.

Contact our experts today to discuss your project and experience the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key properties of PTFE for food and water grade gaskets? Ensure Purity and Safety

- What are the available forms of PTFE semi-finished products? A Guide to Stock Shapes for Machining

- What makes PTFE lip seals suitable for aerospace applications? Unmatched Performance in Extreme Conditions

- What are the overall benefits of using PTFE in lubrication systems? Achieve Unmatched Reliability in Extreme Conditions

- What are the key properties of PTFE that make it suitable for bushes? Discover the Ultimate Self-Lubricating Solution

- What methods are used to join or weld two PTFE sheets together? Achieve a Seamless, Leak-Proof Bond

- How do expanded PTFE gaskets contribute to longer flange service life? Achieve Superior Sealing and Reliability

- What types of components are commonly manufactured from PTFE? Seals, Bearings, Insulators & More