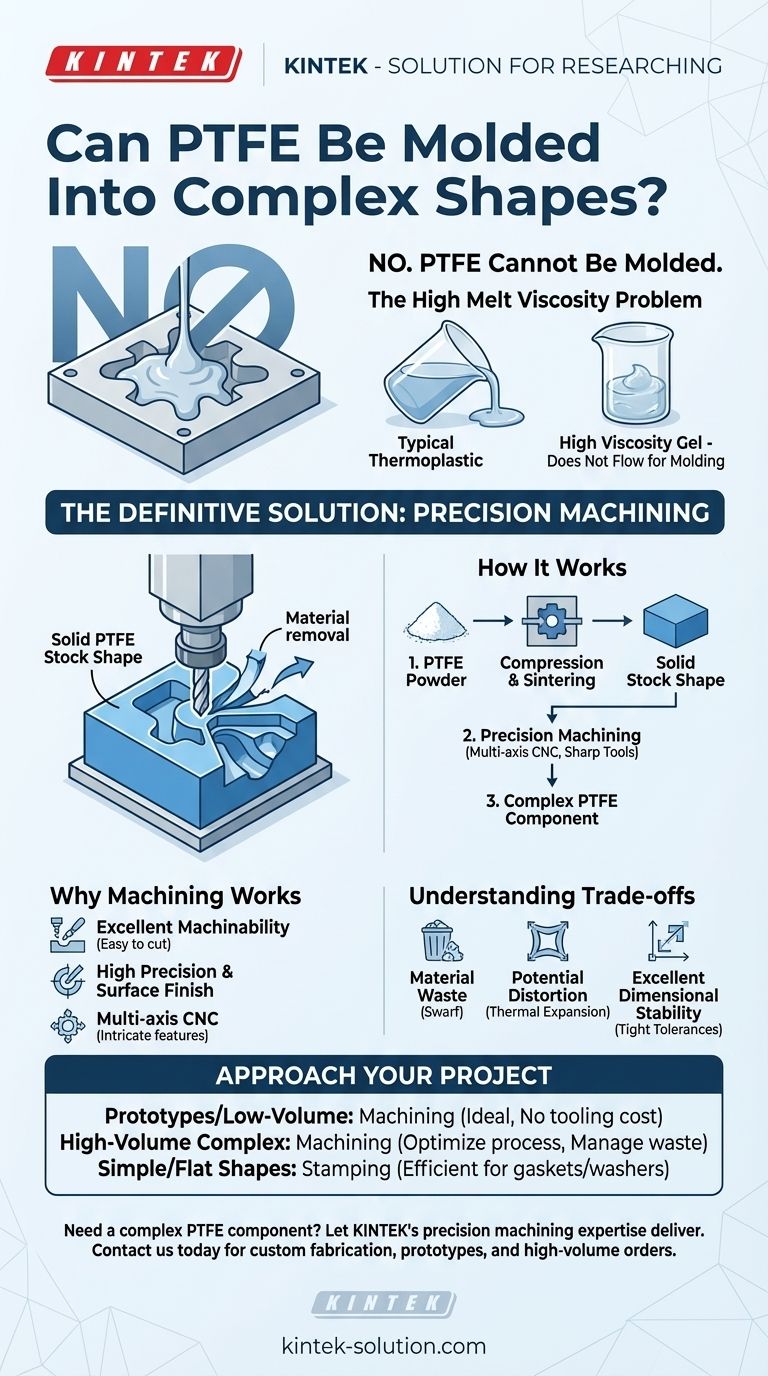

Contrary to conventional plastic processing, PTFE cannot be molded into complex shapes. Its extremely high melting point and gel-like consistency when heated prevent it from flowing into a mold like typical thermoplastics. Therefore, the universal method for creating intricate PTFE components is through machining from solid stock shapes.

The core challenge with PTFE is its inability to be melt-processed. The definitive solution is to shift your mindset from molding to machining, a subtractive process where complex geometries are carved from a solid block or rod of the material.

Why PTFE Defies Traditional Molding

The unique molecular structure of Polytetrafluoroethylene (PTFE) is the source of its desirable properties, but it also dictates its manufacturing limitations.

The Problem of High Melt Viscosity

Unlike common plastics such as polyethylene or polypropylene, PTFE does not truly melt into a low-viscosity liquid. When it reaches its transition temperature (around 327°C), it becomes a translucent, high-viscosity gel that does not flow.

This behavior makes it completely unsuitable for conventional melt-processing techniques like injection molding, which rely on the material flowing easily to fill every detail of a mold cavity.

How Stock Shapes Are Formed

Instead of melting, PTFE parts start as a fine powder. This powder is compressed into a simple preform (like a billet, rod, or sheet) and then heated in a sintering oven.

This process fuses the particles together, creating a solid, dense stock shape. It is these pre-formed shapes that become the raw material for creating complex parts.

The Definitive Solution: Precision Machining

Because it cannot be molded, the industry relies on subtractive manufacturing to produce complex PTFE components. Fortunately, PTFE is exceptionally well-suited for this process.

The Excellent Machinability of PTFE

PTFE is a relatively soft material that is very easy to machine. The process is often compared to machining hardwood and can be done using standard mechanical equipment.

This ease of machining ensures that even highly complex designs can be produced with high precision and excellent surface finishes.

Key Techniques for Precision

For creating complex geometries, multi-axis CNC (3, 4, and 5-axis) machines are essential. These allow the cutting tool to approach the part from multiple angles, enabling the creation of intricate features without repositioning the workpiece.

Achieving the best results requires sharp tools, precise control of cutting speeds and feed rates, and stable workholding methods like vacuum fixtures to prevent the soft material from deforming under clamping pressure.

Starting with Oversized Stock

Most PTFE stock shapes are intentionally sold slightly oversized. This industry practice provides machinists with extra material to ensure they can achieve the final, exact dimensions required by the design specifications.

Understanding the Trade-offs

While machining is the clear solution, it's important to understand the inherent trade-offs of this subtractive process compared to molding.

Inevitable Material Waste

The primary drawback of machining is material waste. Every feature that is cut away from the solid stock becomes scrap material (swarf). For highly complex parts with significant material removal, this can impact the overall cost.

Potential for Distortion

As a soft material with a high coefficient of thermal expansion, PTFE can be prone to distortion. Improper clamping pressure or heat buildup from dull tooling can compromise the dimensional accuracy of the final part.

Excellent Dimensional Stability

Despite these risks, well-executed machining yields highly precise results. The references confirm that both standard and glass-filled PTFE possess excellent dimensional stability, which is critical for ensuring the final part meets tight tolerances.

How to Approach Your PTFE Project

Choosing the right strategy depends on your specific application and production volume.

- If your primary focus is prototypes or low-volume production: Machining is the ideal and most cost-effective method, as it requires no investment in expensive molding tools.

- If your primary focus is a high-volume complex part: Machining remains the required method, but focus on optimizing the process with multi-axis CNC to minimize setups and developing a strategy to manage material costs.

- If your primary focus is very simple, flat shapes: For parts like gaskets or washers, stamping them from a PTFE sheet can be a highly efficient alternative to machining individual components.

Embrace machining as the key to unlocking the full potential of PTFE for your most demanding applications.

Summary Table:

| PTFE Manufacturing Method | Key Characteristic | Best For |

|---|---|---|

| Molding | Not possible; PTFE doesn't flow when heated | N/A |

| Machining from Stock | Subtractive process; excellent machinability | Complex shapes, prototypes, high-precision parts |

| Stamping | Cutting from sheet material | Simple, flat shapes like gaskets |

Need a complex PTFE component? Let KINTEK's precision machining expertise deliver.

While PTFE cannot be molded, our advanced CNC machining capabilities transform solid PTFE stock into highly complex, precision parts for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring dimensional stability and exact specifications.

Contact us today to discuss your project and receive a quote for your custom PTFE seals, liners, labware, and more.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does the low friction coefficient of PTFE expansion bellows benefit fluid flow? Reduce Energy Use & Prevent Blockages

- What are the advantages of using PTFE for spring-energized seal jackets? Superior Performance in Extreme Conditions

- What are the limitations of PTFE coated fasteners regarding abrasion resistance? The Trade-Off for Superior Chemical Protection

- What makes PTFE guide strips a reliable choice for harsh environments? Unmatched Chemical & Thermal Resilience

- What makes PTFE versatile in medical applications? Unlock the Power of Biocompatible Polymers

- Where are PTFE guide strips commonly used? Essential for Hydraulic Cylinders and High-Performance Machinery

- What are some medical applications of PTFE energized seals? Ensuring Reliability and Purity in Medical Devices

- How can PTFE be customized for specific applications? Tailor Performance with Fillers & Fabrication