Choosing the right seal is a critical engineering decision where the choice between an O-ring, square ring, quad ring, or flat gasket depends entirely on the application's specific demands. The primary factors include whether the seal is for a static or dynamic application, the system pressure, and the geometry of the mating surfaces. Elastomeric seals like O-rings work by being squeezed into a groove, while flat gaskets rely on high compressive force between two flat flanges.

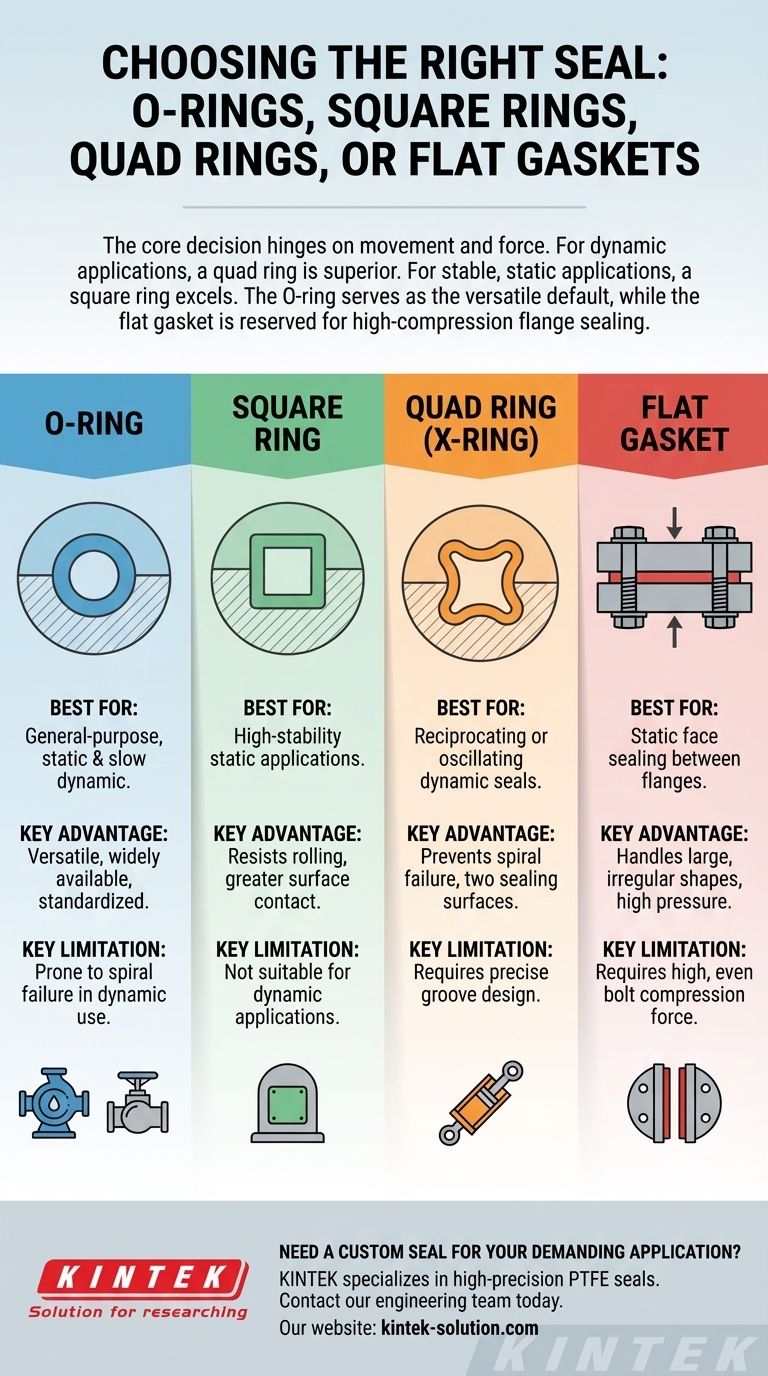

The core decision hinges on movement and force. For dynamic applications, a quad ring is superior. For stable, static applications, a square ring excels. The O-ring serves as the versatile default, while the flat gasket is reserved for high-compression flange sealing.

The Fundamental Sealing Mechanisms

To make an informed choice, you must first understand how these components fundamentally differ in their method of creating a seal.

How Elastomeric Seals Work (O-Rings, Square, Quad)

These seals are designed to be installed in a precisely machined groove, where they are slightly compressed or "squeezed" upon assembly.

This initial squeeze creates a low-pressure seal. As system pressure increases, it pushes the elastomer against the groove walls, energizing the seal and increasing the sealing force.

Crucially, this design means they generally require far less pressure to achieve an effective seal compared to a flat gasket.

How Flat Gaskets Work

A flat gasket, by contrast, does not typically sit in a groove. It is placed between two flat, rigid surfaces (flanges) and creates a seal through high compressive force.

This force, usually applied by bolts, deforms the gasket material, forcing it to flow into the microscopic imperfections of the flange surfaces. This method requires significant clamping force to work effectively.

Comparing the Contenders: Profile by Profile

Each seal's unique geometry dictates its ideal use case.

The O-Ring: The Versatile Standard

The O-ring is the most common and versatile seal due to its simplicity, high availability, and extensive standardization (e.g., AS568 sizes).

Its round profile is effective in a wide range of static and slow-moving dynamic applications, making it the go-to choice for general-purpose sealing in pumps, valves, and cylinders.

The Square Ring: The Stable Static Seal

A square ring, with its rectangular cross-section, offers greater surface contact than an O-ring of the same size.

This flat profile provides excellent stability and resists the rolling or twisting that can occur with O-rings during assembly. It is an outstanding choice for static sealing applications.

The Quad Ring (X-Ring): The Dynamic Specialist

The quad ring features a four-lobed profile that offers two distinct sealing surfaces. This design is its primary advantage in dynamic situations.

The lobes prevent the seal from rolling in its groove during reciprocating or oscillating motion, which is a common failure mode for O-rings known as spiral failure. This makes it the superior choice for hydraulic cylinders and other moving components.

The Flat Gasket: The High-Compression Solution

Flat gaskets are designed almost exclusively for static face sealing, typically between two flanges.

They are ideal for applications with non-standard shapes or where a precision groove cannot be machined. Their effectiveness is entirely dependent on achieving and maintaining a high, evenly distributed bolt load.

Understanding the Trade-offs

No seal is perfect for every situation. Acknowledging their limitations is key to preventing leaks.

Dynamic vs. Static Applications

This is the most critical distinction. While O-rings can handle some slow dynamic movement, they are prone to spiral failure.

For any reciprocating, oscillating, or rotating application, the quad ring is the technically superior and more reliable choice. Square rings and flat gaskets should be limited to purely static applications.

Pressure and Sealing Force

O-rings, square rings, and quad rings are excellent for both vacuum and high-pressure systems because the system pressure itself energizes the seal. However, at very high pressures, they can be forced into the clearance gap, a failure called extrusion.

Flat gaskets require a massive initial sealing force but can be engineered to handle extremely high pressures, as the force is contained by the flanges and bolts.

Installation and Groove Design

The performance of O-rings, square rings, and quad rings is entirely dependent on a correctly designed and machined groove. An incorrect groove depth or width will lead to immediate failure.

Flat gaskets are more forgiving of surface imperfections but are unforgiving of improper or uneven torque on the clamping bolts, which can lead to leaks.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your design.

- If your primary focus is general-purpose, standardized sealing: The O-ring is the proven, widely available, and cost-effective default choice.

- If your primary focus is high-stability static sealing: The square ring offers superior resistance to rolling and is an excellent upgrade for static face or radial seals.

- If your primary focus is reliable dynamic sealing: The quad ring is the correct technical choice to prevent spiral failure and ensure a long service life.

- If your primary focus is sealing large, flat surfaces or flanges: The flat gasket is the only suitable option, designed specifically for high-compression static applications.

By matching the seal's geometry to the application's demands, you ensure a reliable, leak-free design.

Summary Table:

| Seal Type | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| O-Ring | General-purpose, static & slow dynamic | Versatile, widely available, standardized | Prone to spiral failure in dynamic use |

| Square Ring | High-stability static applications | Resists rolling, greater surface contact | Not suitable for dynamic applications |

| Quad Ring (X-Ring) | Reciprocating or oscillating dynamic seals | Prevents spiral failure, two sealing surfaces | Requires precise groove design |

| Flat Gasket | Static face sealing between flanges | Handles large, irregular shapes, high pressure | Requires high, even bolt compression force |

Need a Custom Seal for Your Demanding Application?

Choosing the right seal is critical for performance and reliability. At KINTEK, we specialize in manufacturing high-precision PTFE seals, including O-rings and custom gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise in custom fabrication ensures a perfect fit and superior performance.

Let us help you achieve a leak-free design. Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability