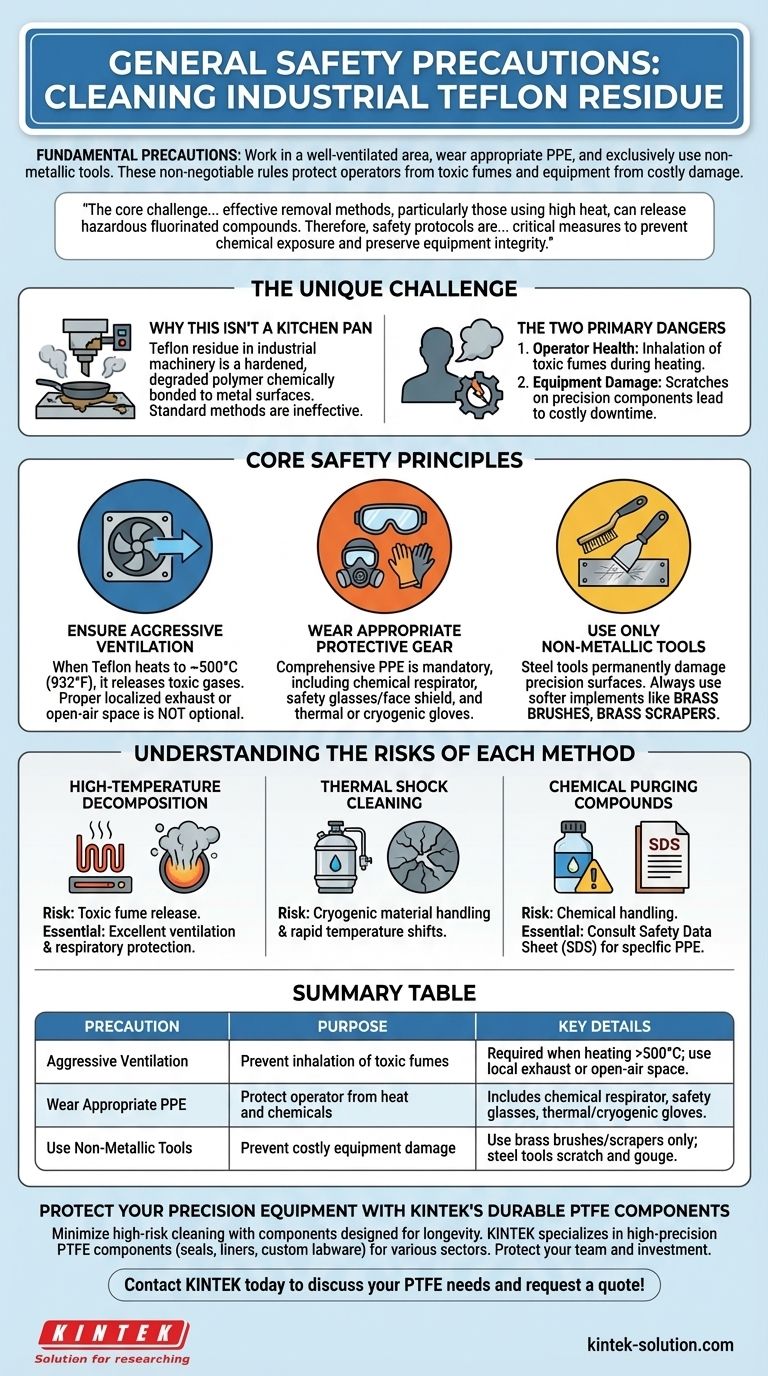

The fundamental safety precautions for cleaning industrial Teflon residue are to work in a well-ventilated area, wear appropriate personal protective equipment (PPE), and exclusively use non-metallic tools to avoid damaging machinery. These non-negotiable rules are designed to protect both the operator from toxic fumes and the expensive equipment from costly damage.

The core challenge in cleaning industrial Teflon residue is that effective removal methods, particularly those using high heat, can release hazardous fluorinated compounds. Therefore, safety protocols are not merely suggestions but critical measures to prevent chemical exposure and preserve equipment integrity.

The Unique Challenge of Industrial Teflon

Why This Isn't a Kitchen Pan

Industrial machinery, such as screws and barrels in extrusion processes, operates under extreme pressure and temperature. Teflon residue in this context is not a simple food stain but a hardened, degraded polymer that has chemically bonded to the metal surfaces.

Standard cleaning methods are completely ineffective. Removing this stubborn residue requires aggressive techniques that introduce significant safety risks if not managed correctly.

The Two Primary Dangers

The entire safety framework is built around mitigating two distinct risks. The first is operator health, primarily concerning inhalation of toxic fumes released during heating.

The second risk is equipment damage. Scratches or gouges on a precision screw or barrel from improper tools can ruin the component, leading to expensive downtime and replacement costs.

Core Safety Principles Explained

Ensure Aggressive Ventilation

When Teflon is heated to high temperatures, around 500°C (932°F), it begins to decompose. This process releases toxic fluorinated gases.

Proper ventilation is not optional; it is the primary defense against inhaling these harmful fumes. This means using localized exhaust systems or working in an open, well-aired space specifically designated for this type of maintenance.

Wear Appropriate Protective Gear

Given the risks of high heat and chemical fumes, comprehensive PPE is mandatory. This typically includes a respirator rated for chemical fumes, safety glasses or a face shield, and thermal gloves to handle hot components.

The specific gear required can vary depending on the cleaning method, such as using cryogenic gloves for thermal shock cleaning with liquid nitrogen.

Use Only Non-Metallic Tools

Steel or other hard metal tools will permanently scratch, score, or gouge the finely machined surfaces of screws and barrels. These imperfections can disrupt material flow, create dead spots where material degrades, and shorten the lifespan of the equipment.

Always use softer implements like brass brushes, brass scrapers, or other specialized non-metallic tools designed for this purpose.

Understanding the Risks of Each Method

High-Temperature Decomposition

This common method involves heating the components to soften the Teflon for mechanical removal. Its primary risk is the release of toxic fumes, making excellent ventilation and respiratory protection essential.

Thermal Shock Cleaning

This technique uses liquid nitrogen to rapidly cool the part, then heats it to crack the residue from thermal expansion. The key hazards here involve the safe handling of cryogenic materials and managing rapid temperature shifts.

Chemical Purging Compounds

Using a purging compound can help break up residue, but it may not remove it completely. The main safety consideration is chemical handling. Always consult the Safety Data Sheet (SDS) for the specific compound to understand its risks and required PPE.

How to Apply This to Your Task

- If your primary focus is operator safety: Prioritize methods that minimize heat. Begin with chemical purging compounds to loosen as much residue as possible before considering any high-temperature techniques.

- If your primary focus is equipment preservation: Strictly enforce the "non-metallic tools only" rule. A brass scraper is always safer for the equipment than a steel screwdriver, regardless of the cleaning method.

- If your primary focus is speed and efficiency: High-temperature cleaning is often fastest, but it carries the highest risk. This method should only be performed with strict adherence to all safety protocols, especially comprehensive ventilation and PPE.

Ultimately, a safe and effective cleaning process protects both your team and your investment.

Summary Table:

| Precaution | Purpose | Key Details |

|---|---|---|

| Aggressive Ventilation | Prevent inhalation of toxic fumes | Required when heating Teflon above 500°C (932°F); use local exhaust or open-air space. |

| Wear Appropriate PPE | Protect operator from heat and chemicals | Includes chemical respirator, safety glasses/face shield, and thermal or cryogenic gloves. |

| Use Non-Metallic Tools | Prevent costly equipment damage | Use brass brushes/scrapers only; steel tools will scratch and gouge precision surfaces. |

Protect Your Precision Equipment with KINTEK's Durable PTFE Components

Cleaning Teflon residue is a high-risk process. Why not minimize the risk with components designed for longevity and easy maintenance? KINTEK specializes in manufacturing high-precision, durable PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our products are engineered to withstand extreme conditions, reducing the frequency and hazard of aggressive cleanings.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application. Protect your team and your investment with components built to the highest standards.

Contact KINTEK today to discuss your PTFE needs and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments