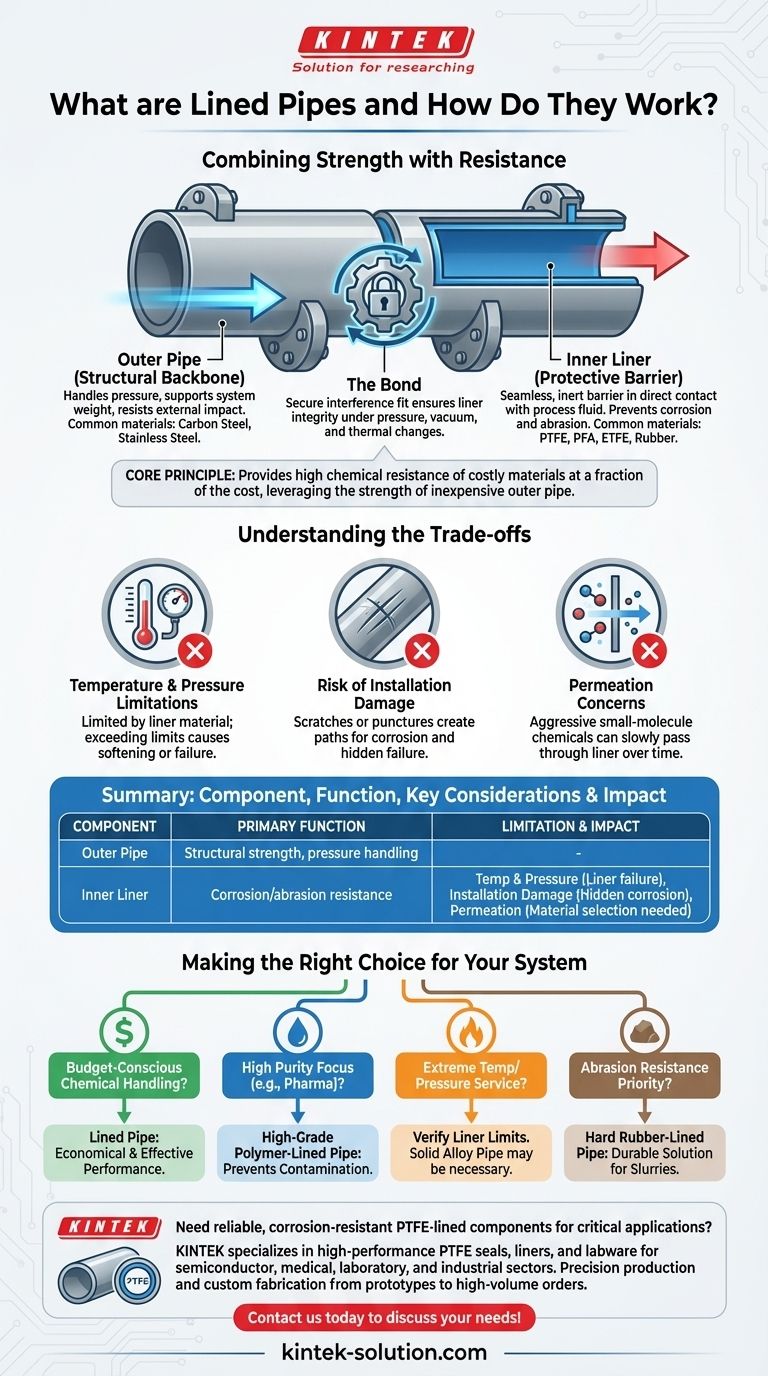

In short, a lined pipe is a composite pipe made of two distinct layers. It combines a strong, rigid outer pipe (typically carbon or stainless steel) with a corrosion-resistant inner liner (often a plastic like PTFE or a specialized rubber). This design leverages the structural integrity of the metal while protecting it from aggressive chemicals or abrasive materials that flow through the system.

The fundamental purpose of a lined pipe is to provide the high chemical resistance of an expensive specialty material at a fraction of the cost. It achieves this by using a robust, inexpensive outer pipe for mechanical strength and a thin inner liner to handle the corrosive media.

The Core Principle: Separating Strength from Resistance

To understand how lined pipes work, it's best to think of them as two components working in tandem, each with a specific job.

The Outer Pipe: The Structural Backbone

The outer pipe, often called the casing or housing, is responsible for all the mechanical duties. Its primary job is to handle pressure, support the system's weight, and resist external impacts.

Materials like carbon steel are excellent for this role because they are strong, rigid, and cost-effective. However, they have poor resistance to many chemicals and will corrode quickly if exposed.

The Inner Liner: The Protective Barrier

The inner liner is the component that is in direct contact with the process fluid. Its sole purpose is to act as a seamless, inert barrier, preventing the corrosive or abrasive fluid from ever touching the outer steel pipe.

Liner materials are chosen for their specific chemical resistance properties. Common liners include PTFE, PFA, and ETFE for extreme chemical and high-temperature service, or various types of rubber for abrasive slurries.

The Bond: Ensuring System Integrity

The liner is securely fitted inside the outer pipe. This is often achieved through an interference fit, where the liner is fractionally larger than the pipe's interior and is mechanically locked into place under pressure. This ensures the liner does not collapse under vacuum or move during thermal expansion and contraction.

Understanding the Trade-offs

While highly effective, lined pipe is a specialized solution with specific limitations that must be respected. Choosing it requires understanding its operational boundaries.

Temperature and Pressure Limitations

The weak point of a lined pipe system is almost always the liner itself. While the steel casing can handle high temperatures and pressures, a plastic liner has a much lower operating ceiling. Exceeding the liner's maximum temperature can cause it to soften, deform, or fail.

Risk of Installation Damage

The liner's integrity is paramount. A small scratch, cut, or puncture in the liner during installation will create a path for corrosive fluid to reach the steel casing. This can cause hidden corrosion that compromises the pipe's structural integrity, leading to a catastrophic failure.

Permeation Concerns

Certain highly aggressive and small-molecule chemicals can slowly pass through, or permeate, a plastic liner over time. In these critical applications, the small amount of permeated fluid can still attack the outer pipe, making material selection crucial.

Making the Right Choice for Your System

Selecting the correct piping material is a balance of performance, safety, and cost. Lined pipe is an excellent tool when used in the right context.

- If your primary focus is handling aggressive chemicals on a budget: Lined pipe is often the most economical and effective solution, providing better performance than stainless steel at a lower cost than solid exotic alloys.

- If your primary focus is high purity: A high-grade polymer-lined pipe prevents product contamination from metal leaching, making it ideal for pharmaceutical or semiconductor applications.

- If your primary focus is extreme high-temperature or high-pressure service: You must verify that the liner's limits are not exceeded; a solid alloy pipe may be a more reliable, albeit more expensive, choice.

- If your primary focus is abrasion resistance: A hard rubber-lined pipe is a proven and durable solution for handling abrasive slurries found in mining and mineral processing.

Ultimately, choosing lined pipe is an engineering decision that prioritizes chemical compatibility and cost-effectiveness for a specific operational window.

Summary Table:

| Component | Material Examples | Primary Function |

|---|---|---|

| Outer Pipe (Casing) | Carbon Steel, Stainless Steel | Provides structural strength, handles pressure, and supports system weight. |

| Inner Liner (Barrier) | PTFE, PFA, ETFE, Rubber | Acts as a corrosion-resistant barrier against aggressive or abrasive fluids. |

| Key Consideration | Limitation | Impact |

| Temperature & Pressure | Limited by liner material (e.g., PTFE softens at high temps) | Exceeding limits can cause liner failure. |

| Installation | Risk of scratches or punctures | Can lead to hidden corrosion and system failure. |

| Chemical Permeation | Small molecules may pass through liner over time | Requires careful material selection for critical applications. |

Need reliable, corrosion-resistant PTFE-lined components for your critical applications? KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and offer custom fabrication—from prototypes to high-volume orders—to meet your exact specifications. Contact us today to discuss how our solutions can enhance your system's durability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What material is used to make PTFE flange gaskets? Choose the Right PTFE for Your Sealing Needs

- What are the applications of ultra-thin PTFE washers (0.03mm – 0.1mm)? Solve Microscopic Engineering Challenges

- How is PTFE used in sports rehabilitation and medical devices? Unlock Superior Biocompatibility and Performance

- What are the key properties of Teflon bearings? Engineered for Extreme Environments

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What factors have contributed to the expansion of the global supply chain for Teflon machined parts? Key Drivers and Industry Insights

- What is PTFE commonly known as and why is it used for gaskets? | Superior Sealing Solutions

- What technological advancements have been made in PTFE lined check valves? Boost Efficiency & Reliability