Unlike traditional plastics, Polytetrafluoroethylene (PTFE) cannot be processed by melting it and injecting it into a mold. Due to its extremely high melt viscosity, it must first be compressed from a powder into a solid shape, a process often called molding. This solid shape is then heated in a controlled oven in a process called sintering, which fuses the particles together into a durable mass.

Because PTFE does not truly melt and flow like other polymers, its processing is more analogous to powdered metallurgy or ceramics than to conventional plastic injection molding. The fundamental strategy involves compressing PTFE powder into a solid "preform" and then sintering it, creating stock shapes that are subsequently machined to final specifications.

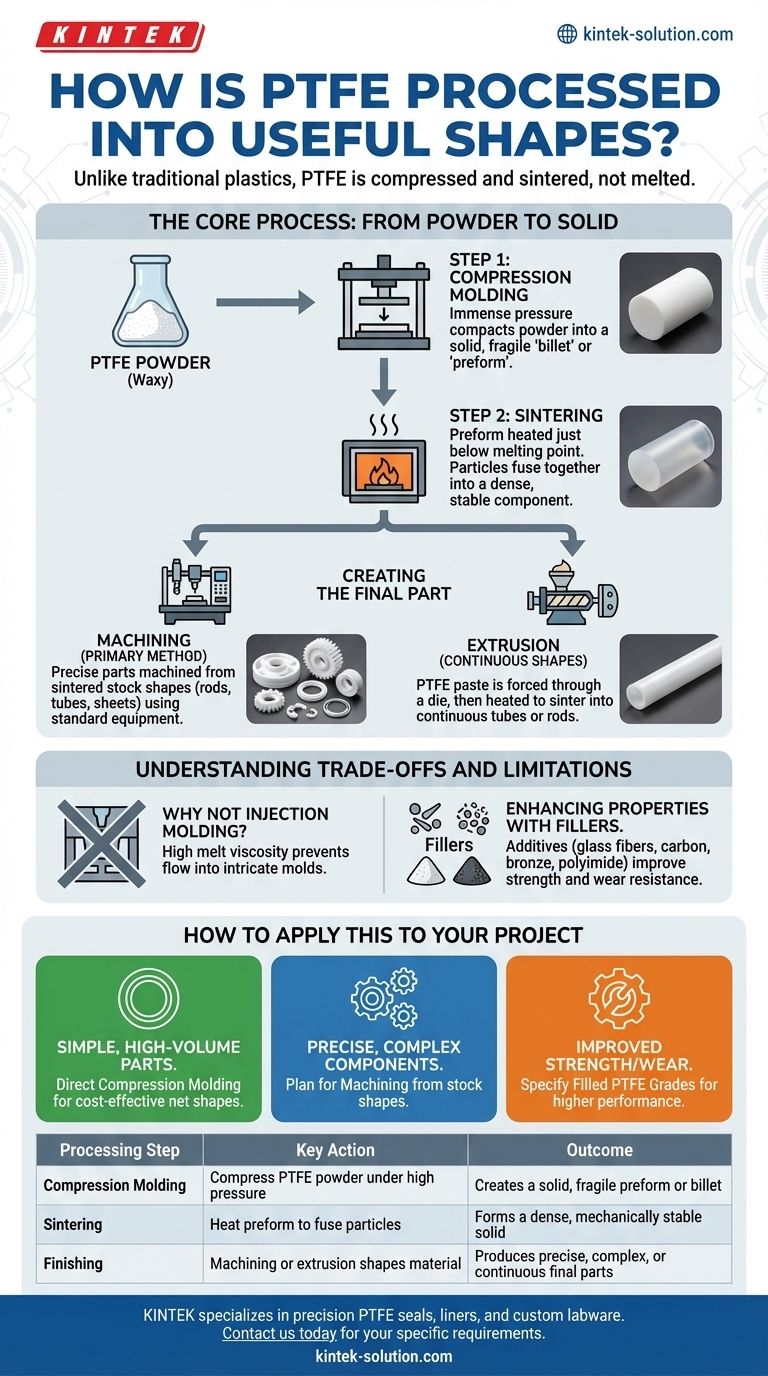

The Core Process: From Powder to Solid

The unique properties of PTFE dictate a multi-step manufacturing workflow. Understanding this sequence is critical to designing parts that can be produced effectively and economically.

The Starting Material: A Waxy Powder

PTFE begins as a fine, waxy, powder-like substance created through either suspension or dispersion polymerization. This raw powder is the base material that is formed into solid shapes.

Step 1: Compression Molding

The first step is to place the PTFE powder into a mold and apply immense pressure. This compacts the powder into a solid, but still fragile, shape known as a "billet" or "preform." This process gives the part its basic form, whether it's a simple rod, a thick sheet, or a basic seal.

Step 2: Sintering

The compressed preform is then carefully removed from the mold and placed in a sintering oven. It is heated to a high temperature, just below its actual melting point, for a specific period. This does not melt the material but causes the individual PTFE particles to fuse together, creating a solid, dense, and mechanically stable component.

Creating the Final Part

Once a solid, sintered stock shape is produced, it must be finished into its final form. This is almost always accomplished through one of two methods.

Machining: The Primary Finishing Method

The vast majority of detailed PTFE components are created by machining them from sintered stock shapes like rods, tubes, and sheets. PTFE is known for being exceptionally easy to machine using standard equipment, including tools typically used for woodworking or metalworking. Its dimensional stability ensures that precise and complex geometries can be achieved through turning, milling, and drilling.

Extrusion for Continuous Shapes

For creating long, continuous profiles like tubes or rods, a process called extrusion can be used. In this method, a PTFE paste (a mix of powder and a lubricant) is forced through a shaped die. The resulting profile is then heated to remove the lubricant and sinter the PTFE, creating a finished, continuous length.

Understanding the Trade-offs and Limitations

The unique processing of PTFE offers distinct advantages but also imposes important design constraints.

Why Not Injection Molding?

PTFE's high melt viscosity prevents it from flowing into the intricate cavities of an injection mold. This is the single most important factor differentiating its processing from common thermoplastics like nylon or polycarbonate.

Constraints on Shape Complexity

Because the initial form is created by compression, highly complex net-shape parts with undercuts or intricate internal features are generally not feasible to mold directly. Designs must be compatible with being machined from a simpler stock shape.

Enhancing Properties with Fillers

The mechanical properties of pure PTFE, such as its resistance to wear or deformation under load (creep), can be limited. To overcome this, additives like glass fibers, carbon, bronze, or polyimide are blended with the raw powder. These "filled" or "compounded" grades offer significantly improved performance.

How to Apply This to Your Project

Choosing the right approach depends entirely on your application's specific requirements for geometry, performance, and volume.

- If your primary focus is creating simple, high-volume parts like seals or bushings: Direct compression molding of a PTFE compound can be a cost-effective method to produce the net shape.

- If your primary focus is producing precise, complex components: Plan to machine your parts from standard PTFE stock rods, sheets, or tubes.

- If your primary focus is improving mechanical strength or wear resistance: Specify a filled grade of PTFE (e.g., glass-filled, carbon-filled) to meet your performance targets.

By understanding this unique "compress, sinter, and machine" workflow, you can effectively leverage the powerful properties of PTFE for your most demanding applications.

Summary Table:

| Processing Step | Key Action | Outcome |

|---|---|---|

| Compression Molding | PTFE powder is compressed under high pressure | Creates a solid, fragile preform or billet |

| Sintering | Preform is heated to fuse particles without melting | Forms a dense, mechanically stable solid |

| Finishing | Machining or extrusion shapes the sintered material | Produces precise, complex, or continuous final parts |

Need high-performance PTFE components for your project? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in compression molding, sintering, and machining ensures superior quality and durability. Contact us today to discuss your specific requirements and leverage our advanced fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key characteristics of PTFE plugs? Master Performance in Extreme Conditions

- How do PTFE lined check valves differ from traditional swing check valves? A Guide to Superior Flow Control

- How does the heat resistance of Teflon plastic sheets benefit high-temperature applications? Ensure Unmatched Stability and Reliability

- What tools and techniques are recommended for machining PTFE? Achieve Precision and a Clean Finish

- What industrial applications utilize extruded PTFE rods? Key Uses in Chemical, Aerospace & More

- What factors should be considered when selecting a PTFE lip seal? Optimize Your Sealing System for Reliability

- What post-machining steps improve PTFE surface finish? Achieve a Smooth, High-Performance Surface

- How can PTFE bellows be customized for different applications? Tailor Flexibility, Pressure Rating, and Purity