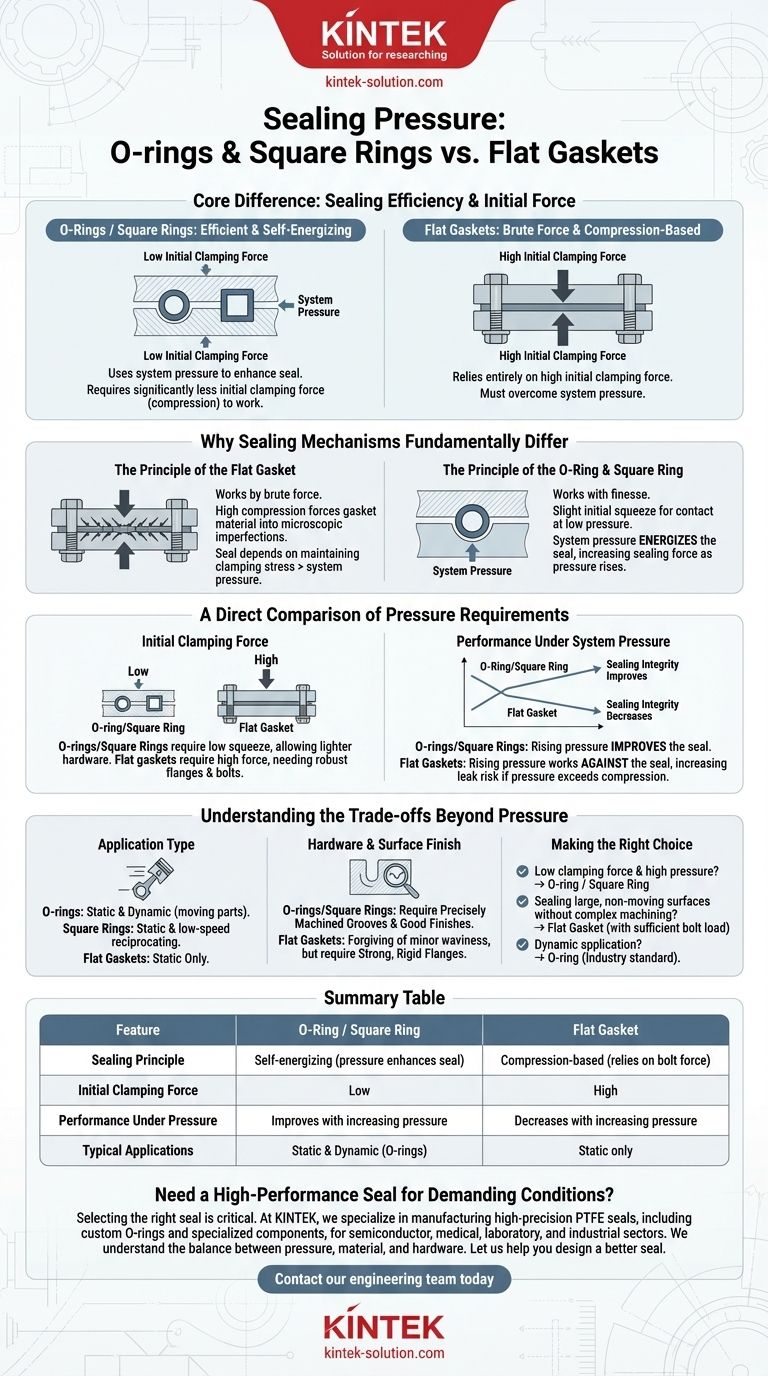

In terms of sealing pressure, O-rings and square rings are fundamentally more efficient than flat gaskets. They require significantly less initial clamping force (compression) to create an effective seal because they are designed to use the system's own pressure to enhance their sealing capability. A flat gasket, by contrast, relies entirely on a high initial clamping force to work.

The critical distinction is how the seal is energized. O-rings and square rings are "self-energizing," using system pressure to their advantage. Flat gaskets are "compression-based," relying solely on the mechanical force applied to them.

Why Sealing Mechanisms Fundamentally Differ

To understand the difference in pressure requirements, we must first examine how each type of seal functions at a mechanical level. Their designs dictate their relationship with both clamping force and system pressure.

The Principle of the Flat Gasket

A flat gasket works by brute force. It is placed between two flanges, and a high clamping force (usually from bolts) is applied to compress the gasket material.

This high compression stress forces the gasket material to flow into the microscopic imperfections of the flange surfaces, creating a barrier. The seal's integrity depends entirely on maintaining a clamping stress that is greater than the system pressure trying to force a leak.

The Principle of the O-Ring and Square Ring

An O-ring or square ring works with more finesse. It sits in a precisely machined groove and is given a slight initial squeeze (compression) to ensure it makes contact with the sealing surfaces.

This initial squeeze creates the seal at zero or low pressure. As system pressure is introduced, it acts on the ring, pushing it firmly against the opposite side of the groove. This pressure energizes the seal, meaning the sealing force increases as the system pressure increases.

A Direct Comparison of Pressure Requirements

The different operating principles lead to vastly different requirements for both the initial installation and performance under load.

Initial Clamping Force

Flat gaskets require high clamping force. The flanges and bolts must be robust enough to generate and withstand the significant load needed to make the gasket material flow and seal properly.

O-rings and square rings require only a low initial squeeze. The hardware's primary job is to hold the components together and provide this slight compression, not to generate massive sealing stress. This often allows for lighter and less expensive hardware designs.

Performance Under System Pressure

For a flat gasket, rising system pressure works against the seal. It actively tries to push the flanges apart and overcome the initial clamping force. If the system pressure exceeds the compressive stress on the gasket, a leak will occur.

For an O-ring or square ring, rising system pressure improves the seal (up to the material's physical limits). The pressure differential across the ring actively forces it more tightly into the sealing surfaces, reinforcing its integrity.

Understanding the Trade-offs Beyond Pressure

While O-rings and square rings are more efficient regarding pressure, the choice of seal depends on the total context of the application.

Application Type: Static vs. Dynamic

O-rings are exceptional for both static (non-moving) and dynamic (moving parts, like pistons or rotating shafts) applications.

Square rings are primarily used in static applications but can be suitable for some low-speed reciprocating motion.

Flat gaskets are exclusively for static applications, such as pipe flanges, covers, and access panels. They cannot be used where parts move relative to one another.

Hardware and Surface Finish Requirements

O-rings and square rings demand precisely machined grooves with good surface finishes to function correctly. Any imperfection in the groove can create a leak path.

Flat gaskets are more forgiving of minor surface waviness but require strong, rigid flanges that won't bend or warp under the high bolt loads required for a reliable seal.

Making the Right Choice for Your Application

Selecting the correct seal is a matter of aligning the component's strengths with your primary engineering goal.

- If your primary focus is low clamping force and high-pressure sealing: An O-ring or square ring is the superior choice, as they use system pressure to enhance the seal.

- If your primary focus is sealing between two large, non-moving surfaces without complex machining: A flat gasket is a simple and effective solution, provided you can apply and maintain sufficient bolt load.

- If you need a seal for any dynamic (moving) application: An O-ring is the industry-standard and most reliable option.

Ultimately, understanding how a seal interacts with pressure is the key to designing a reliable and efficient system.

Summary Table:

| Feature | O-Ring / Square Ring | Flat Gasket |

|---|---|---|

| Sealing Principle | Self-energizing (pressure enhances seal) | Compression-based (relies on bolt force) |

| Initial Clamping Force | Low | High |

| Performance Under Pressure | Improves with increasing pressure | Decreases with increasing pressure |

| Typical Applications | Static & Dynamic (O-rings) | Static only |

Need a High-Performance Seal for Demanding Conditions?

Selecting the right seal is critical for the reliability and efficiency of your system. At KINTEK, we specialize in manufacturing high-precision PTFE seals, including custom O-rings and specialized components, for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between pressure requirements, material compatibility, and hardware design. Whether you need a prototype for testing or a high-volume production run, our expertise in custom fabrication ensures you get a seal that performs flawlessly under pressure.

Let us help you design a better seal. Contact our engineering team today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does Teflon's performance in extreme temperatures benefit industrial applications? Ensuring Reliable Performance from -200°C to +260°C

- What are some physical properties of PTFE with fillers? Enhance Strength, Wear, and Thermal Performance

- What is the purpose of the built-in spring in PTFE shaft seals? To Ensure a Reliable, Long-Lasting Seal

- What are the main differences between FR4 and PTFE PCB laminate materials? Choose the Right Material for Your Application

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- How is MoS2 (Moly) typically combined in PTFE applications? Synergistic Fillers for Low Friction

- What types of contaminants should be avoided with PTFE-lined bearings? Protect Your Investment and Maximize Performance

- What are the advantages of Teflon square bars? Solve Extreme Engineering Challenges