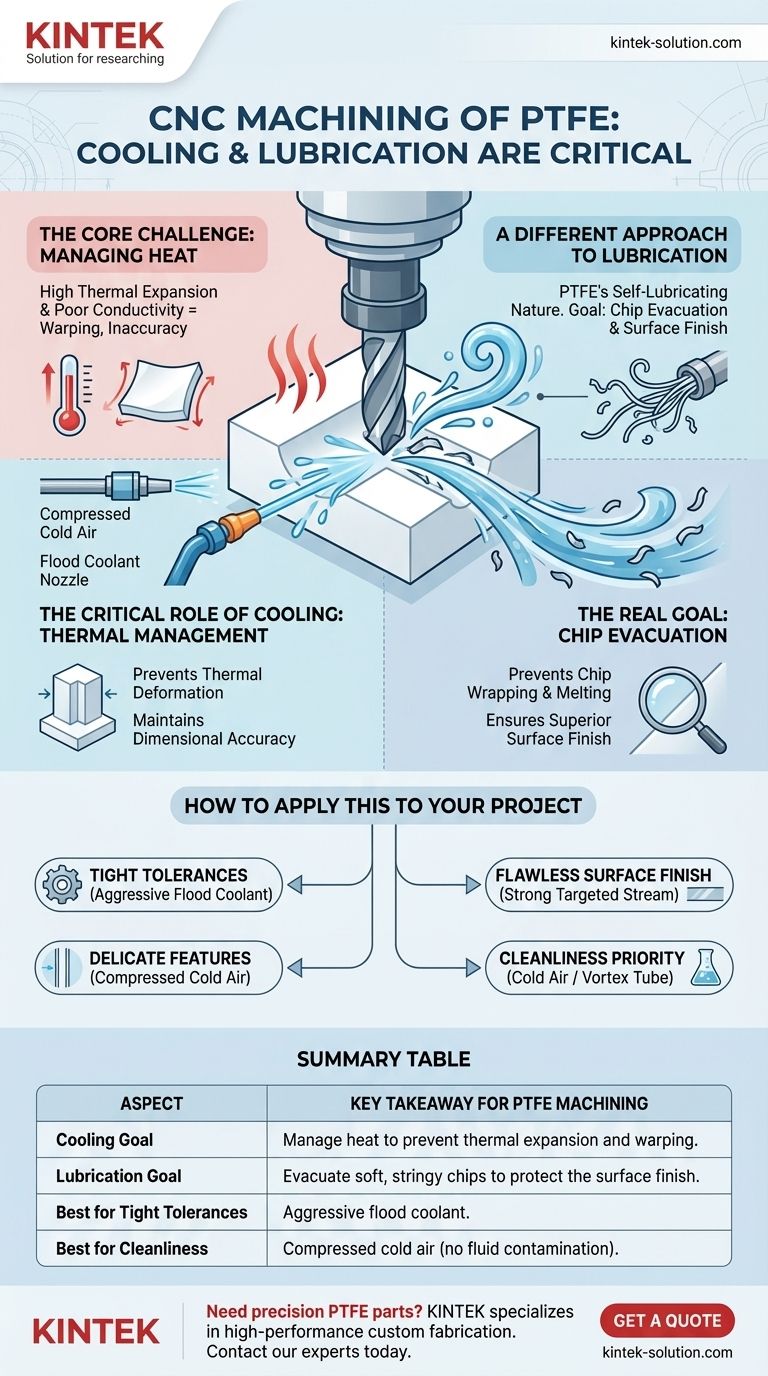

In CNC machining PTFE, cooling and lubrication are not just beneficial; they are critical. Their primary role is to manage the extreme heat sensitivity of the material. Effective cooling directly prevents thermal deformation and warping, ensuring dimensional accuracy, while the fluid stream serves the essential function of clearing chips to maintain a clean cut and superior surface finish.

Because PTFE is a poor thermal conductor with a high rate of thermal expansion, active cooling is the single most important factor in maintaining dimensional stability. Its self-lubricating nature means the goal of a fluid is less about friction and more about aggressive chip evacuation.

The Core Challenge: Managing Heat in PTFE

Understanding how PTFE behaves with heat is fundamental to machining it successfully. Its unique properties create a specific set of challenges that cooling and lubrication are designed to solve.

High Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among polymers. Even a small increase in temperature can cause the material to expand significantly, destroying tight tolerances.

Poor Thermal Conductivity

Unlike metals, PTFE is an excellent thermal insulator. It does not dissipate heat away from the cutting tool. This causes heat to concentrate right at the point of contact, leading to localized melting and deformation.

The Consequence: Warping and Inaccuracy

The combination of high expansion and poor conductivity is a recipe for failure. The localized heat causes the material to expand unevenly, resulting in warped parts, inaccurate features, and a high scrap rate if not properly managed.

The Critical Role of Cooling

Cooling is your primary defense against the thermal challenges of PTFE. It is not an optional step for achieving high-quality results.

Preventing Thermal Deformation

The main job of a cooling system is to extract heat from the workpiece and tool as quickly as it is generated. This stabilizes the material's temperature and prevents the expansion that leads to warping.

Maintaining Dimensional Accuracy

By keeping the part at a consistent, cool temperature throughout the machining process, you ensure that the dimensions you cut are the dimensions you have when the part is finished. This is essential for holding tight tolerances.

Common Cooling Methods

Compressed cold air is an effective and clean option for lighter cuts, offering good heat removal and chip clearing. For more aggressive machining or deep cuts, a flood coolant (typically a water-soluble oil) is superior for its ability to carry away more heat and aggressively flush chips.

A Different Approach to Lubrication

While the terms "cooling" and "lubrication" are often used together, their functions diverge when machining PTFE.

PTFE's Self-Lubricating Nature

PTFE has an exceptionally low coefficient of friction. The material is inherently slippery, which is why it is often used for non-stick coatings and bearings. Therefore, the need for a lubricant to reduce friction between the tool and the material is far less critical than with metals.

The Real Goal: Chip Evacuation

The primary function of the fluid stream in PTFE machining is chip control. PTFE produces long, stringy, and soft chips that can easily wrap around the tool or melt onto the part's surface. A strong flow of coolant or air is vital to clear these chips from the cutting zone immediately.

Enhancing Surface Finish

By effectively clearing chips, the fluid prevents them from being recut or marring the finished surface. This action is crucial for achieving a smooth, high-quality surface finish free from melted material.

Understanding the Pitfalls

Failing to properly manage the thermal environment is the most common reason for poor results when machining PTFE.

The Risk of Insufficient Cooling

Any interruption or inadequacy in the cooling stream will allow heat to build up instantly. This can ruin a part in seconds, making consistent and well-aimed cooling absolutely essential.

The Problem of Chip Wrapping

If the air or coolant flow is too weak, chips will not evacuate properly. This wrapping can increase heat, damage the cutting tool, and destroy the surface finish of the component.

Coolant Contamination

While effective, liquid coolants can absorb into porous grades of PTFE. For applications in the medical or food industries, you must ensure the coolant is approved for the part's end-use or opt for a clean method like cold air.

How to Apply This to Your Project

Your strategy for cooling and lubrication should be dictated by the specific requirements of your component.

- If your primary focus is holding tight tolerances: Prioritize aggressive and consistent cooling with a flood coolant to eliminate any chance of thermal expansion.

- If your primary focus is a flawless surface finish: Use a strong, targeted stream of coolant or cold air specifically to ensure chips are cleared instantly from the cutting path.

- If you are machining thin-walled or delicate features: Use compressed cold air to minimize cutting pressure while still providing the essential cooling to prevent the feature from warping.

- If part cleanliness is the top priority: Rely exclusively on a vortex tube or other cold air gun system to avoid any potential fluid contamination.

Mastering thermal control is the key to unlocking precise and repeatable results when machining PTFE.

Summary Table:

| Aspect | Key Takeaway for PTFE Machining |

|---|---|

| Cooling Goal | Manage heat to prevent thermal expansion and warping. |

| Lubrication Goal | Evacuate soft, stringy chips to protect the surface finish. |

| Best for Tight Tolerances | Aggressive flood coolant. |

| Best for Cleanliness | Compressed cold air (no fluid contamination). |

Need to machine PTFE components with precision and reliability? At KINTEK, we specialize in the custom fabrication of high-performance PTFE parts for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing the unique thermal challenges of PTFE ensures your prototypes and high-volume orders meet the strictest dimensional and surface finish requirements.

Contact our PTFE machining experts today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How resistant are Teflon encapsulated O-rings to compression set? Achieve Long-Term Sealing Reliability

- What is the purpose of the holes in PTFE lined butterfly valves? Ensure Perfect Alignment for Leak-Proof Sealing

- What production processes are used to manufacture precision PTFE components? A Guide to CNC Machining & More

- What are some specific applications of Teflon lip seals in industrial machinery? Engineered for Extreme Conditions

- Does carbon fiber-filled PTFE damage shafts? Ensure Longevity with Proper Material Pairing

- What types of fluids can PTFE control valves handle? Master Corrosive Chemicals with Confidence

- How does the temperature resistance of PTFE O-rings compare to other materials? Superior Performance from -250°C to +260°C

- How do PTFE sliding bearings work? Support Heavy Loads with Minimal Friction