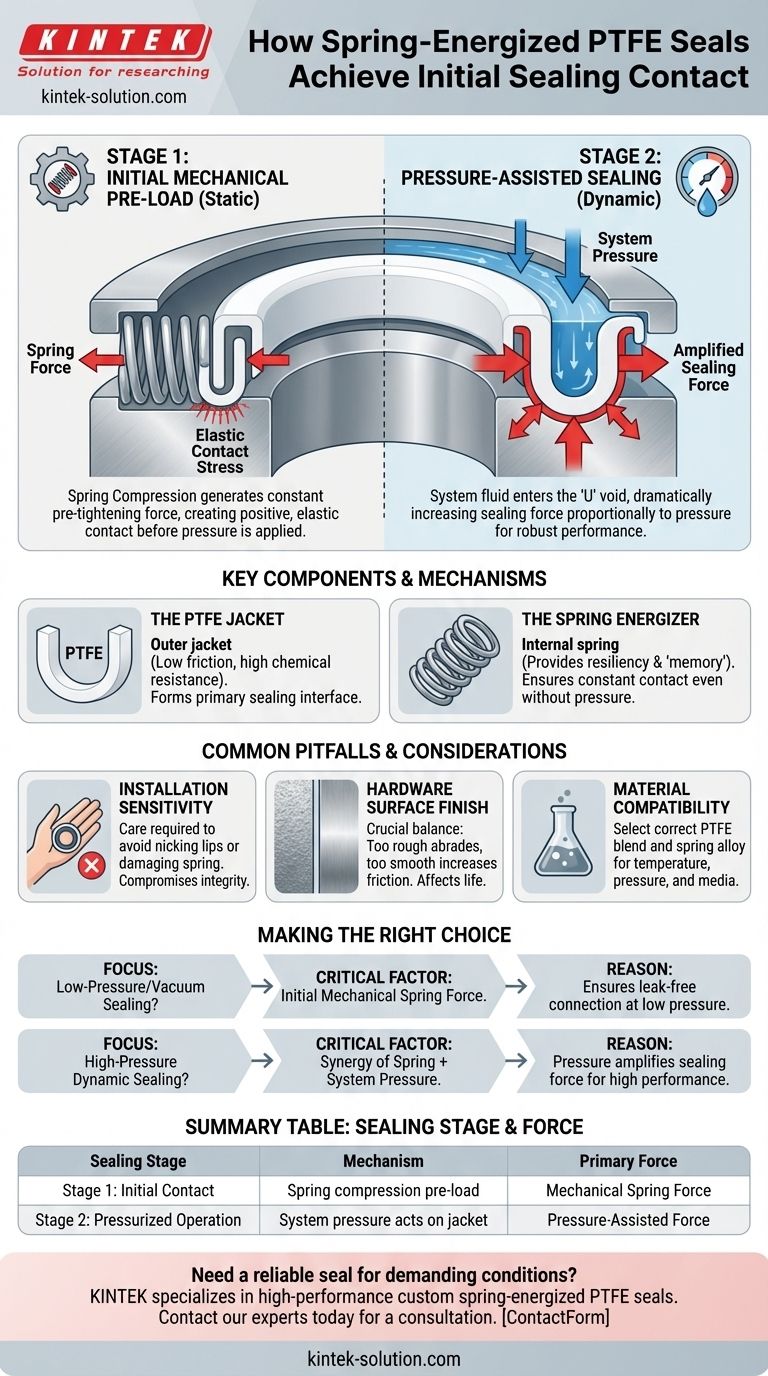

The initial seal of a spring-energized PTFE ring is established by mechanical force. When the seal is installed into its designated groove, the internal metal spring is compressed. This compression generates a constant, pre-tightening reaction force that pushes the flexible PTFE jacket outwards, creating a positive, elastic contact stress against the sealing surfaces before any system pressure is even applied.

The core principle is a two-stage sealing mechanism. An internal spring provides a constant, initial mechanical force for low-pressure and static sealing, while the system's fluid pressure is intelligently channeled by the seal's design to amplify this force for robust, high-pressure performance.

The Sealing Mechanism: A Step-by-Step Breakdown

To fully grasp how these seals work, it's best to think of their function in two distinct phases: the initial static state and the dynamic pressurized state.

Stage 1: The Initial Mechanical Pre-Load

The spring is the heart of the initial seal. Its sole purpose is to provide a consistent outward (or inward, depending on the seal type) force on the PTFE jacket.

This spring energizer ensures that the seal lips are held firmly against the hardware surfaces from the moment of installation. This action creates the initial contact stress necessary to form a barrier against leakage at zero or very low pressures.

This mechanical force is also critical for compensating for minor imperfections in the hardware, thermal expansion or contraction, and any potential material creep in the PTFE jacket over time.

Stage 2: Pressure-Assisted Sealing

Once the system is pressurized, the seal's design truly begins to work. The U-shaped profile of the PTFE jacket is engineered to catch the system fluid.

This pressure enters the void inside the "U" and acts upon the inner surface of the seal jacket. The result is a dramatic increase in the sealing force, directly proportional to the system pressure itself.

This "self-energizing" characteristic ensures that as pressure increases, the sealing force also increases, maintaining a tight, reliable seal throughout the entire operating pressure range. The combined force from the spring and the system pressure is always greater than the pressure of the fluid trying to escape.

Understanding the Key Components

A spring-energized seal is a composite of two materials working in synergy. Each part plays a distinct and critical role.

The PTFE Jacket

The outer jacket, typically made from a blend of Polytetrafluoroethylene (PTFE), serves as the primary sealing interface. Its material properties provide low friction for dynamic applications and high chemical resistance against aggressive media.

The Spring Energizer

The internal spring, often made of stainless steel or other high-performance alloys, provides the resiliency and "memory" that the more rigid PTFE material lacks. It ensures the jacket remains in constant contact with the sealing surface, even when no pressure is present.

Common Pitfalls and Considerations

While highly effective, spring-energized seals are precision components. Their performance depends on proper handling and application design.

Installation Sensitivity

Unlike a simple O-ring, the installation of a spring-energized seal requires care. Nicking the soft PTFE lips or damaging the spring during assembly can immediately compromise the seal's integrity and lead to premature failure.

Hardware Surface Finish

The effectiveness of the PTFE jacket relies heavily on the quality of the mating hardware surfaces. A surface that is too rough will rapidly abrade the seal lip, while a surface that is too smooth may not provide adequate lubrication retention, increasing friction and wear.

Material Compatibility

The specific blend of the PTFE jacket and the material of the spring energizer must be carefully selected for the application's temperature, pressure, and chemical media. Choosing the wrong combination can lead to chemical degradation or loss of spring force at temperature extremes.

Making the Right Choice for Your Application

Understanding this dual-action mechanism is key to diagnosing issues and selecting the right design.

- If your primary focus is low-pressure or vacuum sealing: The initial force provided by the spring energizer is the most critical factor for ensuring a leak-free connection.

- If your primary focus is high-pressure dynamic sealing: You are relying on the synergy between the spring's initial load and the system pressure amplifying that sealing force during operation.

- If you are experiencing initial static leaks: The root cause is likely related to insufficient spring force, improper installation damaging the seal lip, or an out-of-specification hardware finish.

By mastering the principle of mechanical pre-load followed by pressure assistance, you can effectively leverage the high-performance capabilities of these advanced seals.

Summary Table:

| Sealing Stage | Mechanism | Primary Force | Key Benefit |

|---|---|---|---|

| Stage 1: Initial Contact | Spring compression provides pre-load | Mechanical Spring Force | Ensures sealing at zero/low pressure and compensates for system imperfections |

| Stage 2: Pressurized Operation | System pressure acts on the PTFE jacket | Pressure-Assisted Force | Sealing force increases with system pressure for robust high-performance sealing |

Need a reliable seal for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision spring-energized seals. Our seals are engineered to deliver the critical initial mechanical pre-load and self-energizing pressure response detailed in this article, ensuring leak-free performance in the most challenging semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, tailoring the PTFE blend and spring energizer to your specific temperature, pressure, and chemical media requirements.

Let us provide the sealing solution you need. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments